Visible photocatalytic functional fabric and preparation method thereof

A technology of functional fabrics and visible light, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of long operation period, complicated operation, low efficiency, etc., and achieve low preparation cost and simple operation , good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

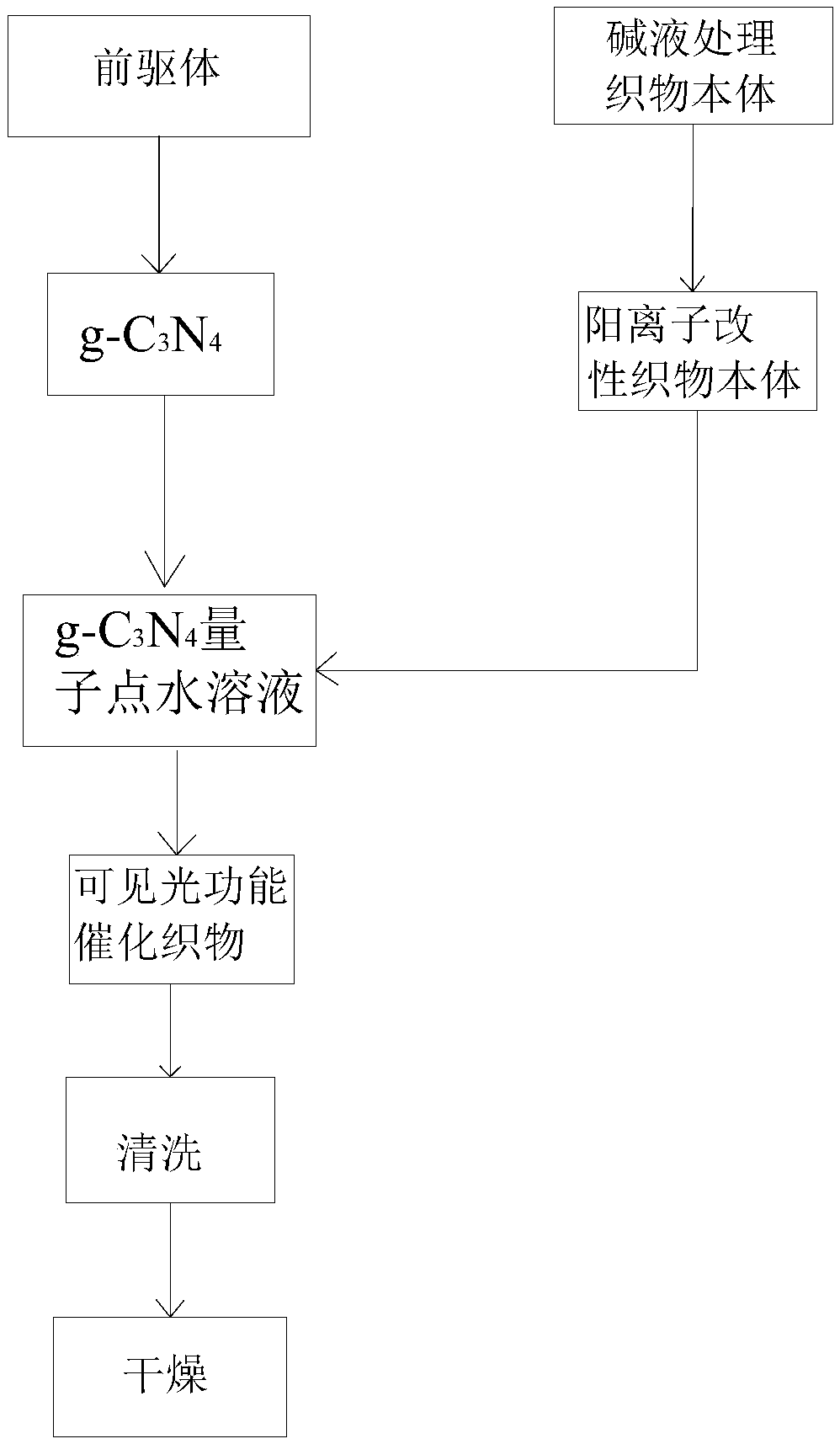

[0020] A method for preparing a visible light catalytic functional fabric, comprising the steps of:

[0021] (1) Treat the fabric body with lye. In the present invention, the lye is sodium hydroxide solution or potassium hydroxide solution, both of which are strong alkali solutions, so that a large number of -OH functional groups are formed on the surface of the fabric body for subsequent bonding.

[0022] Specifically, the treatment of the fabric body with lye can be carried out in the following manner: the fabric body is completely immersed in the lye, and can be stirred for 5 minutes to 30 minutes at a speed of 200r / min to 600r / min, so that the fabric body In full contact with the lye, more -OH functional groups are formed on the surface of the fabric body, and the temperature is 60 ° C ~ 100 ° C, so that sodium hydroxide or potassium hydroxide has a greater solubility, avoiding its deposition, and cannot carry out alkali well. deal with. Preferable settings: the concentr...

Embodiment 1

[0037] First, the polyimide fabric body is completely immersed in the sodium hydroxide solution with a concentration of 5g / L and a temperature of 60°C, and it is continuously stirred for 30min at a speed of 200r / min, and then the polyimide fabric body is used Rinse with deionized water and dry. Then immerse the polyimide fabric body treated with alkali solution in a nitrogen heterocyclic cationic compound solution with a temperature of 60°C and a pH value of 9 for 5 minutes, and use double dipping under the pressure of the paddle car to 0.1MPa. Padding is performed in the second padding process, followed by pre-baking at 100° C. for 5 minutes, and then baking at 160° C. for 1 minute to obtain the cationic modified polyimide fabric body.

[0038] First, the precursor thiourea was heated up to 500°C at a constant rate of 2°C / min, and then calcined at a constant temperature for 4 hours, then cooled to 480°C at a constant rate of 5°C / min, calcined at a constant temperature for 1 h...

Embodiment 2

[0042] First, completely immerse the viscose fabric body in a potassium hydroxide solution with a concentration of 20g / L and a temperature of 100°C, and stir continuously for 5 minutes at a speed of 600r / min, and then wash the viscose fabric body with deionized water and dry. Then, the body of the viscose fabric treated with alkali solution was immersed in the epoxy compound solution with a temperature of 100°C and a pH value of 11 for 60 minutes, and the two-dipping and two-rolling process was adopted under the condition that the pressure of the padding machine was 0.5MPa. Carry out padding, then pre-bake at 100°C for 10 minutes, and then bake at 160°C for 4 minutes to obtain the cationic modified viscose fabric body.

[0043] First, the precursors dicyandiamine and melamine were heated up to 600°C at a constant rate of 15°C / min, and then calcined at a constant temperature for 1 hour, then cooled to 540°C at a constant rate of 8°C / min, calcined at a constant temperature for 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com