Indoor visible-light-responsive catalyst, and preparation method and application thereof

A catalyst and visible light technology, applied in the field of indoor environment, can solve the problems of limited reaction rate, single organic gas, limited use effect, etc., to achieve the effect of optimizing reaction efficiency, increasing conversion and utilization, and large market potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

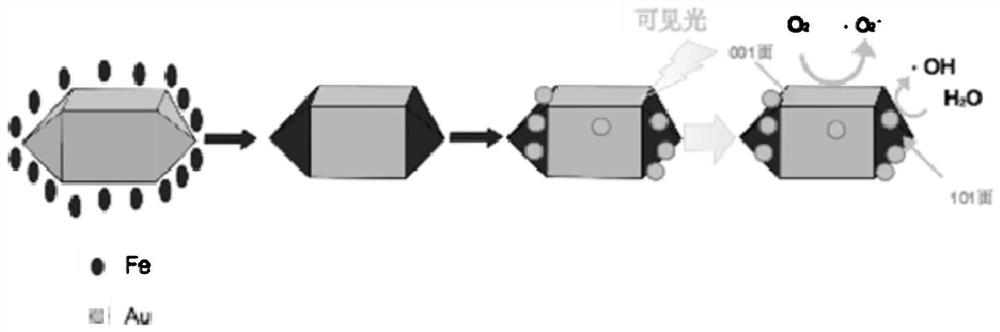

Method used

Image

Examples

Embodiment 1

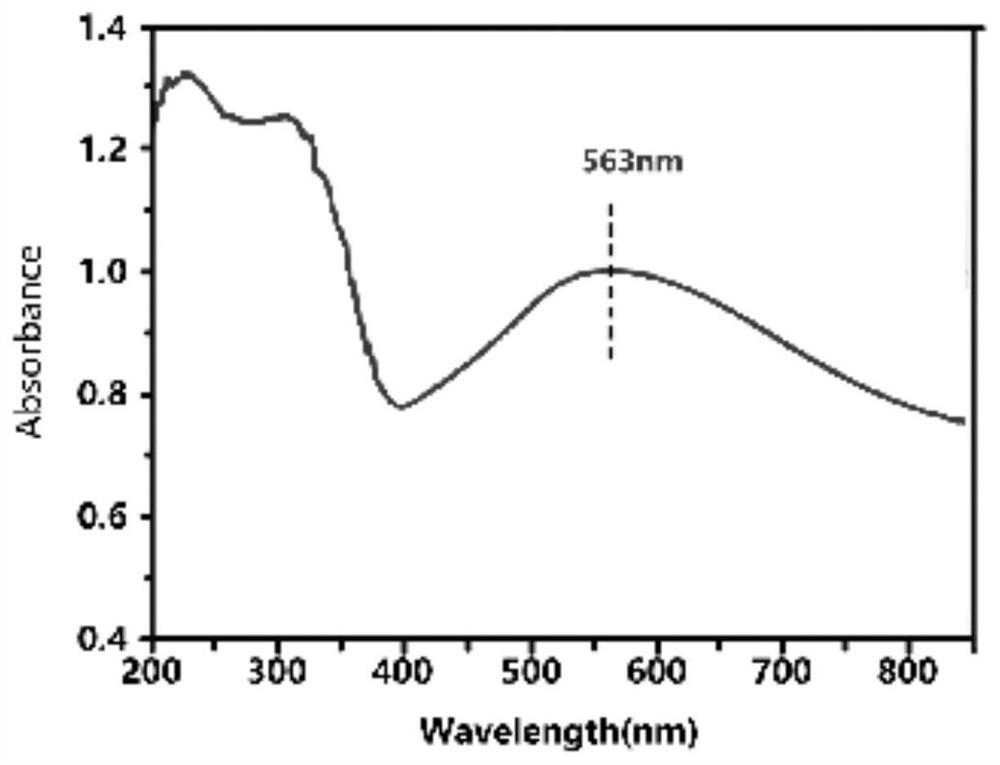

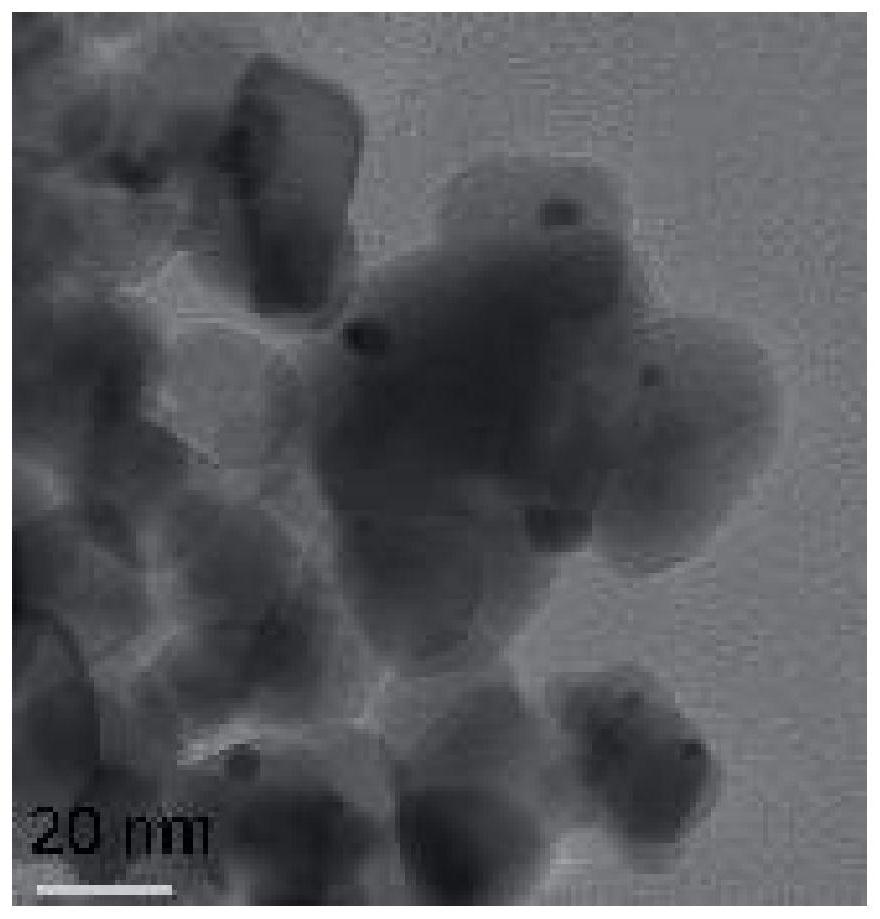

[0037] Dissolve 10g of titanium tetrachloride, 30ml of isopropanol, 10ml of deionized water and 1ml of diethylenetriamine in a beaker sonically at room temperature to form liquid A; take 10ml of ethanol, 20ml of deionized water, 1ml of nitric acid and 0.1g of chlorine at room temperature After 5 minutes of ultrasonication, the ferric oxide forms liquid B; add liquid A and liquid B into the polytetrafluoroethylene liner, mix and ultrasonically homogenize; keep the constant temperature in an oven at 100°C, and heat for 0.5 hours; naturally cool to room temperature, After sonication, it was centrifuged, washed three times with ethanol and deionized water, and dried to obtain Fe@TiO 2 powder.

[0038] The above 10gFe@TiO 2 Powder, 0.1g chloroauric acid and 0.1g polyvinylpyrrolidone were added to 30ml deionized water to dissolve water solution C; 0.5g hydrogen peroxide was added to 5ml deionized water to form solution D; under ice bath conditions, accompanied by 500r / min Add solu...

Embodiment 2

[0040] At room temperature, 10g of isopropyl titanate, 30ml of isopropanol, 10ml of deionized water and 1ml of diethylenetriamine were ultrasonically dissolved in a beaker to form liquid A; at room temperature, 10ml of ethanol, 20ml of deionized water, 1ml of nitric acid and 0.1g Ferric nitrate was uniformly ultrasonicated for 5 minutes to form liquid B; add liquid A and liquid B into the polytetrafluoroethylene liner, mix and ultrasonically homogenize; keep the constant temperature in the oven at 100°C, heat for 0.5 hours; naturally cool to room temperature, After sonication, it was centrifuged, washed three times with ethanol and deionized water, and dried to obtain Fe@TiO 2 powder.

[0041] The above 10gFe@TiO 2Powder, 0.1g chloroauric acid and 0.1g polyvinylpyrrolidone were added to 30ml deionized water to dissolve water solution C; 0.5g sodium borohydride was added to 5ml deionized water to form solution D; under ice bath conditions, accompanied by 500r / min Add solution...

Embodiment 3

[0043] At room temperature, 16g of isopropyl titanate, 42ml of isopropanol, 20ml of deionized water and 3ml of diethylenetriamine were ultrasonically dissolved in a beaker to form liquid A; at room temperature, 20ml of ethanol, 30ml of deionized water, 2ml of nitric acid and 0.5g Ferric nitrate was uniformly ultrasonicated for 10 minutes to form liquid B; add liquid A and liquid B into the polytetrafluoroethylene liner, mix and ultrasonically homogenize; and continue to heat in an oven at a constant temperature of 150°C for 2 hours; naturally cool to room temperature, After sonication, it was centrifuged, washed three times with ethanol and deionized water, and dried to obtain Fe@TiO 2 powder.

[0044] The above 15gFe@TiO 2 Powder, 0.15g of chloroauric acid and 0.15g of polyvinylpyrrolidone were added to 60ml of deionized water to dissolve to prepare aqueous solution C; 0.75g of sodium borohydride was added to 12ml of deionized water to form solution D; under ice bath conditi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com