Metal-loaded titanium-based catalyst and preparation method thereof

A supported catalyst and supported technology, applied in the direction of metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the constraints of catalyst performance improvement and application, metal particle size Difficult to control and other problems, to achieve excellent catalytic performance, easy control of preparation parameters, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

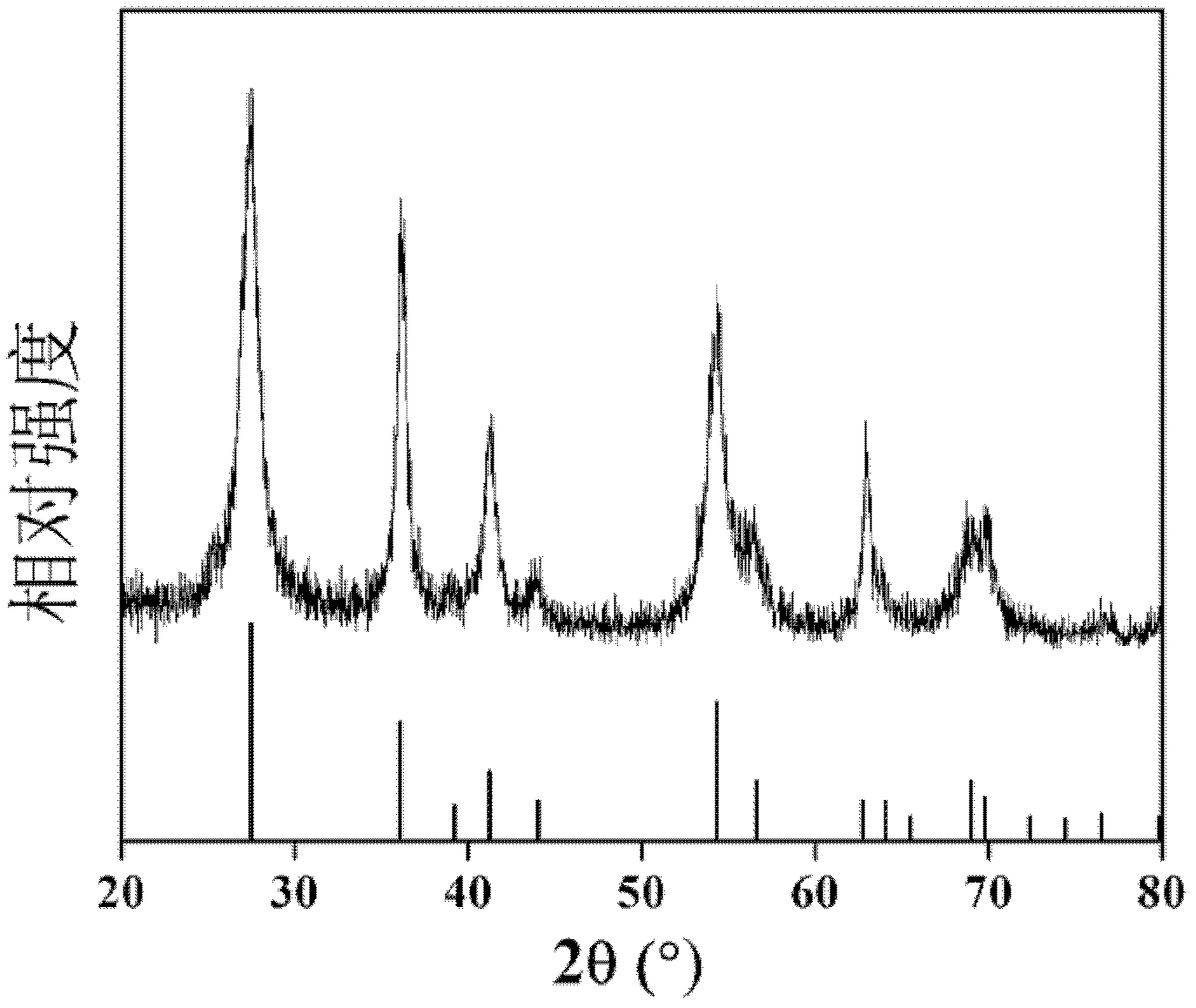

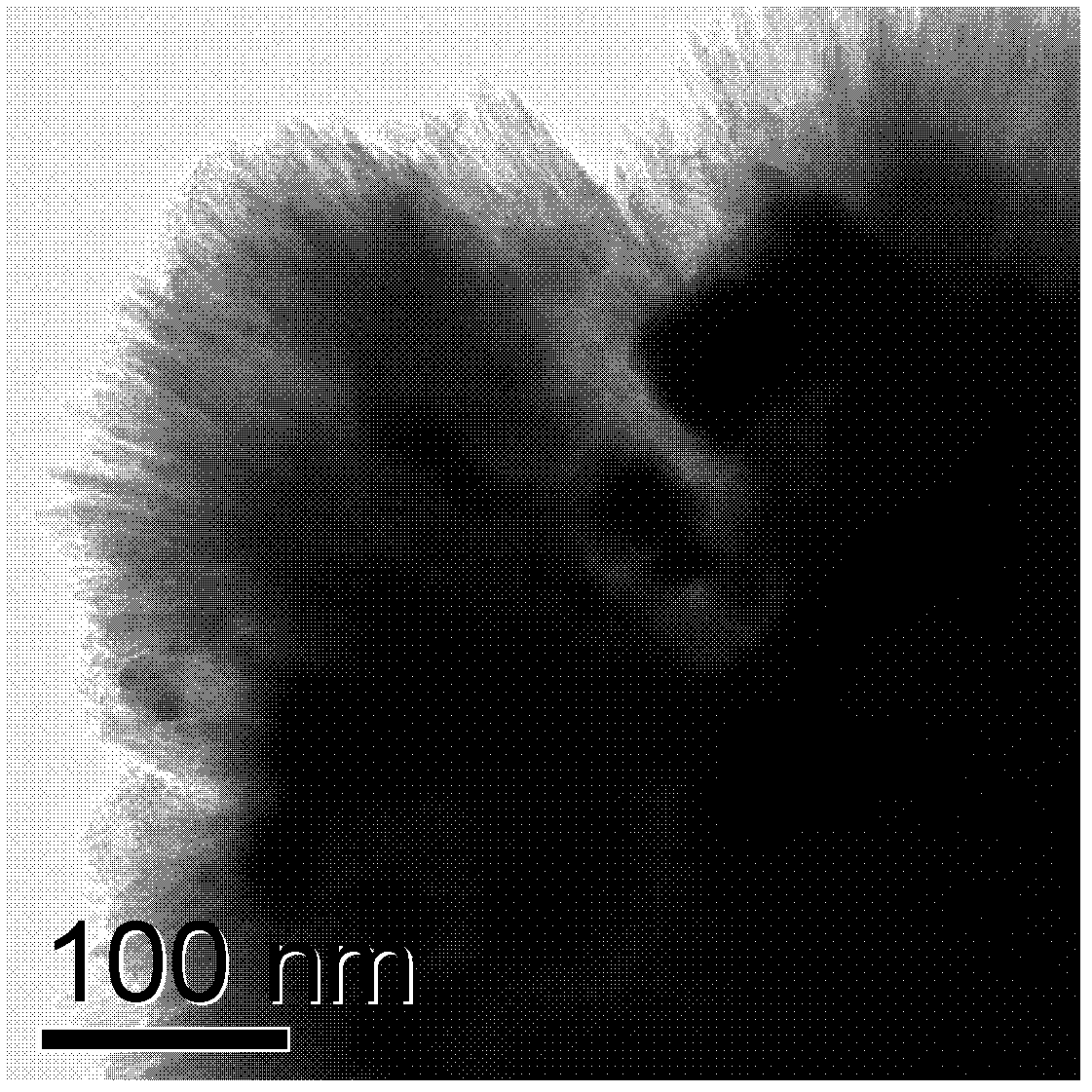

[0038] At room temperature, 48.2 grams of titanium trichloride (20wt%, TiCl 3 ) And 120.5 g of saturated sodium chloride solution were placed in a 200 mL three-necked flask, and nitrogen was introduced, and the oxygen in the reaction system was removed by magnetic stirring for 30 minutes. Then it was heated in an oil bath at a constant temperature of 100°C for 12 hours. Wait for the flask to gradually cool to room temperature, quickly wash the obtained precipitate, and then redisperse it into 120 mL of distilled water, stir it magnetically, and heat to 80°C. Then 3 mL of 0.02M palladium chloride solution was injected, and after 15 minutes of reaction, 21 mL of palladium chloride solution of the same concentration was injected again. Keep the temperature at a constant temperature for 12 hours to obtain a precipitate. The above reaction processes are all carried out in a nitrogen atmosphere. The precipitate was washed with deionized water several times, and dried in an oven at 6...

Embodiment 2

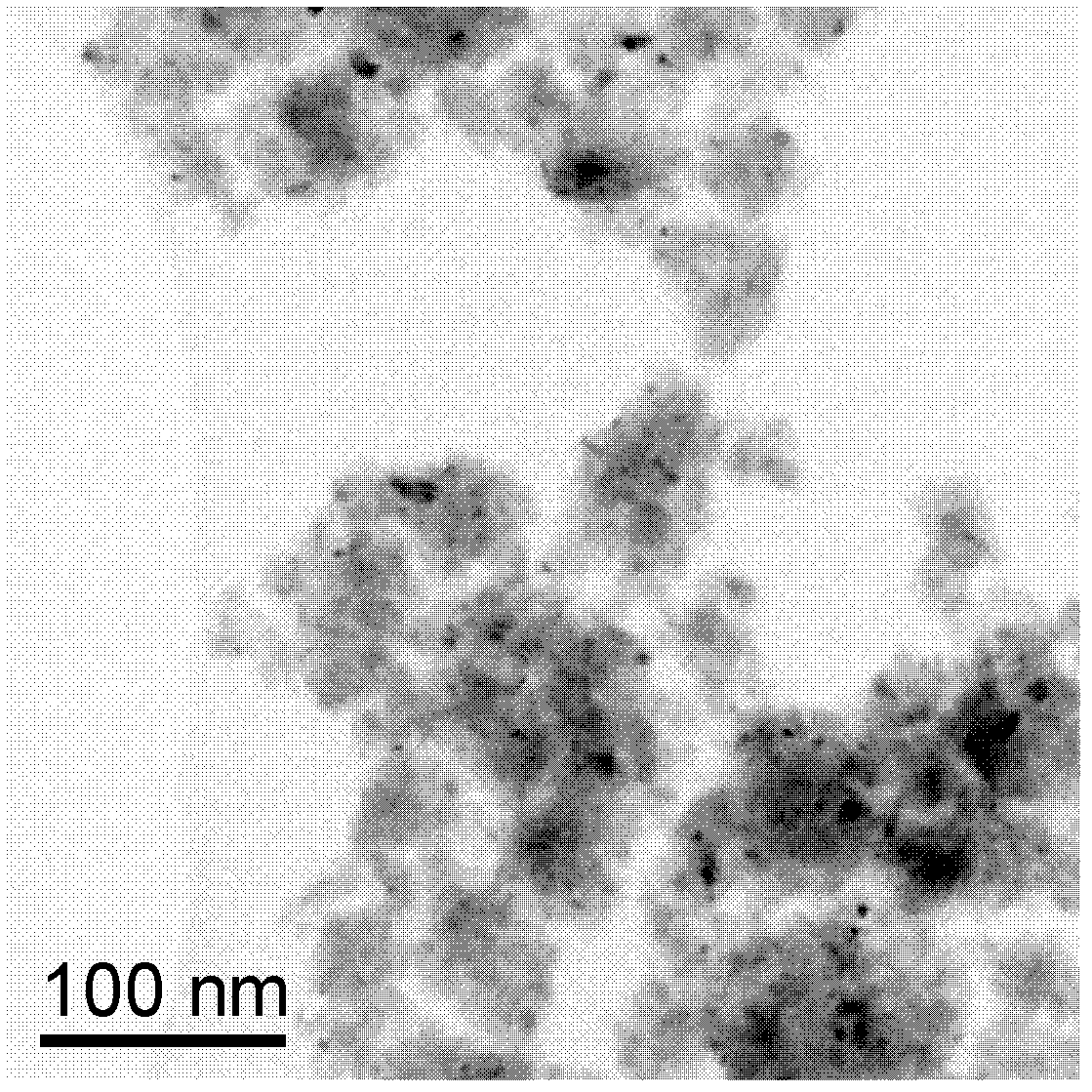

[0040] At room temperature, 48.2 grams of titanium trichloride (20wt%, TiCl 3 ) And 120.5 g of saturated sodium chloride solution were placed in a 200 mL three-necked flask, and nitrogen was introduced, and the oxygen in the reaction system was removed by magnetic stirring for 30 minutes. Then it was heated in an oil bath at a constant temperature of 80°C for 12 hours. Wait for the flask to gradually cool to room temperature, quickly wash the obtained precipitate, and then redisperse it into 120 mL of distilled water, stir it magnetically, and heat it to 100°C. Then 6mL of 0.02M copper chloride and 14.1mL of 0.02M palladium chloride solution were injected, and after 15 minutes of reaction, 18mL of 0.02M copper chloride and 42.3mL of 0.02M palladium chloride solution were injected again. Keep the temperature at a constant temperature for 12 hours to obtain a precipitate. The above reaction processes are all carried out in a nitrogen atmosphere. The precipitate was washed with d...

Embodiment 3

[0042] At room temperature, 24.1 grams of titanium trichloride (20wt%, TiCl 3 ) And 60.25 g of saturated sodium chloride solution were placed in a 200 mL three-necked flask, and nitrogen was introduced, and the oxygen in the reaction system was removed by magnetic stirring for 30 minutes. Then it was heated in an oil bath at a constant temperature of 90°C for 12 hours. Wait for the flask to gradually cool to room temperature, quickly wash the obtained precipitate, and then redisperse it in 120 mL of distilled water, stir it magnetically, and heat to 60°C. Then inject 6.3 mL of 0.01M chloroauric acid solution, and inject 6.3 mL of the same concentration of chloroauric acid solution again after 15 minutes of reaction. Keep the temperature at a constant temperature for 12 hours to obtain a precipitate. The above reaction processes are all carried out in a nitrogen atmosphere. The precipitate was washed with deionized water several times, and dried in an oven at 40° C. for 12 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com