Household gas burner

A gas burner and gas technology, which is applied to burners, gas fuel burners, combustion methods, etc., can solve problems such as affecting the performance of cooking appliances, low gas combustion efficiency, complex structure, etc., and achieve convenient and accurate fire control and adjustment. Improve overall performance and firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

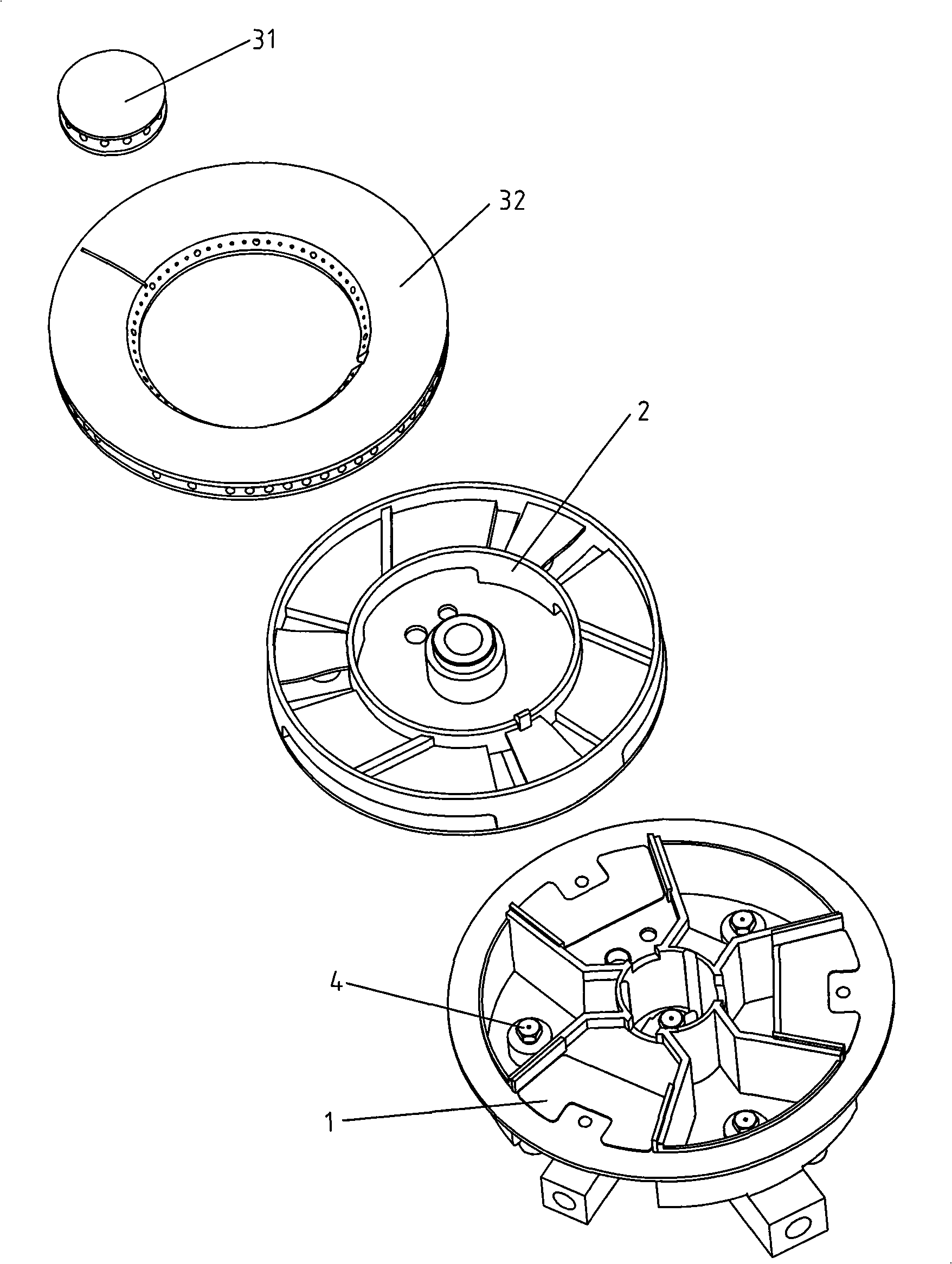

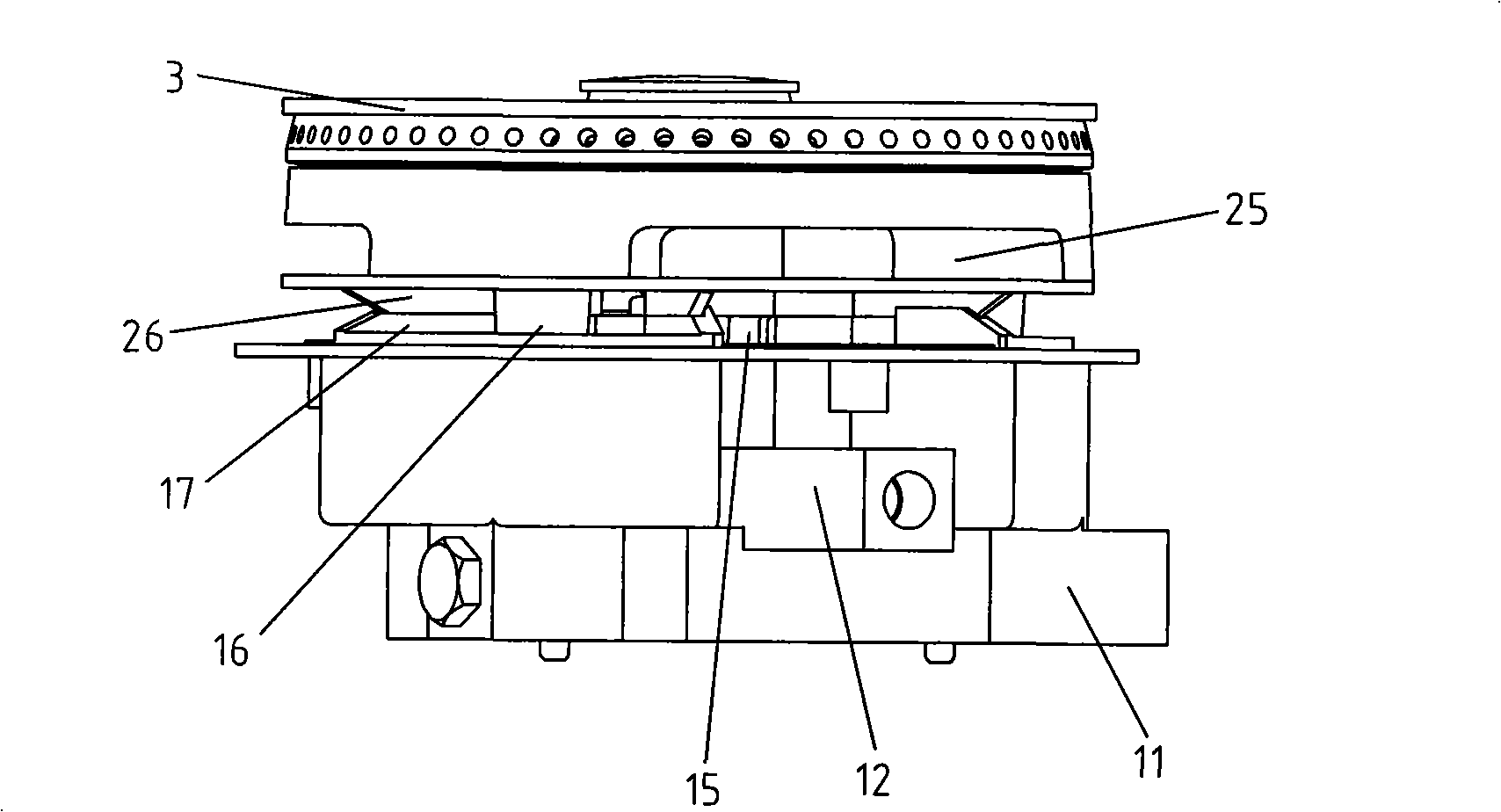

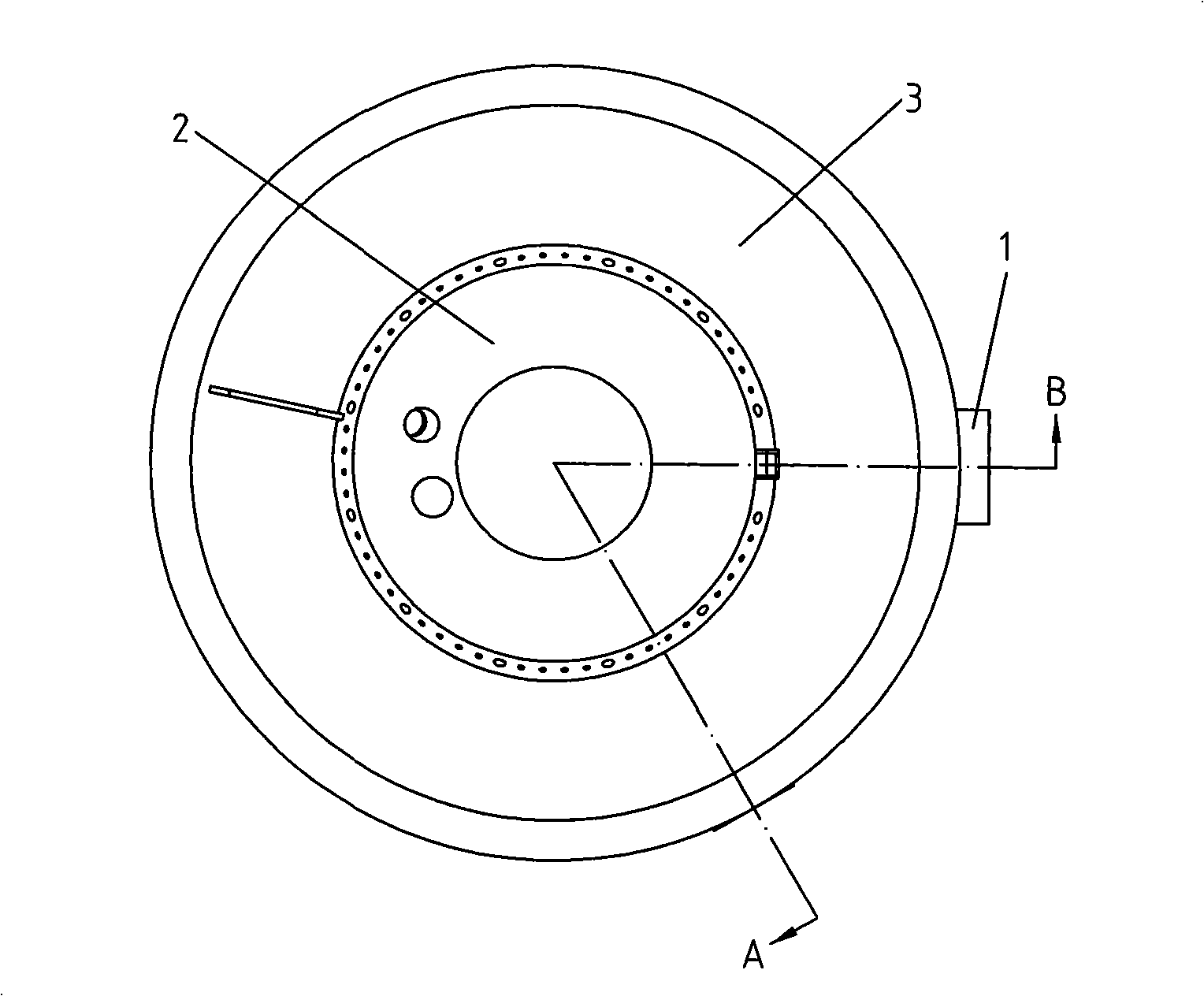

[0039] see Figure 1-Figure 13 , the present invention includes a gas distribution device 1, a gas mixing device 2, a fire cover 3 and a nozzle 4, wherein the gas mixing device 2 is located on the gas distribution device 1, the fire cover 3 is located on the gas mixing device 2, and the nozzle 4 is fixed on the gas distribution device within 1.

[0040] The gas distribution device 1 in this embodiment has an integrated structure, that is, the gas distribution device 1 is integrally formed, and includes a gas supply pipe, a distribution chamber, a central primary air inlet 15, a peripheral primary air inlet 16, and distribution device ribs 17 , No. 1 hole 18 of the ignition pin and No. 1 hole 19 of the thermocouple, wherein the air supply pipe includes the main air supply pipe 11 and the auxiliary air supply pipe 12, and the distribution chamber includes a central distribution chamber 13 and three peripheral distribution chambers 14. A central distribution chamber 13 is locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com