Garbage incinerator and incineration method

A technology of waste incinerator and grate, which is applied in the direction of combustion method, incinerator, combustion type, etc., and can solve the problems of reducing the service life of the grate and damaging the grate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

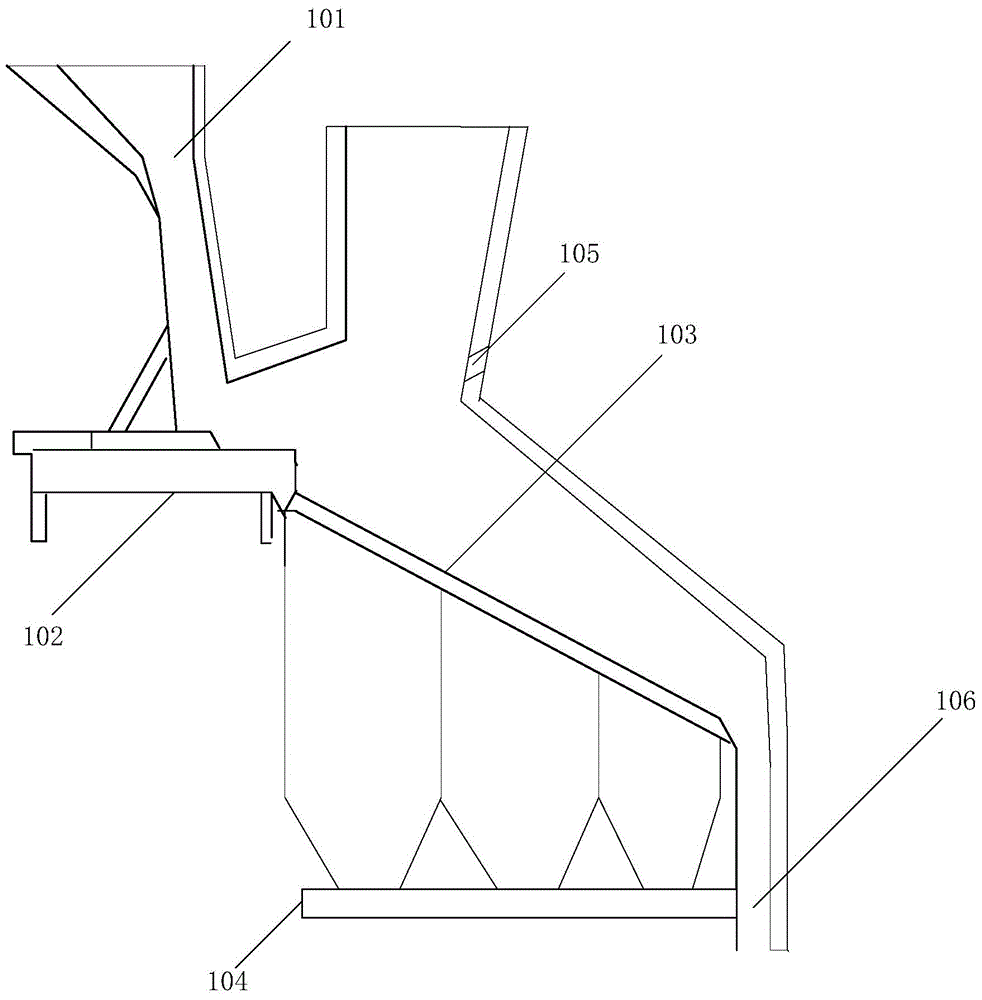

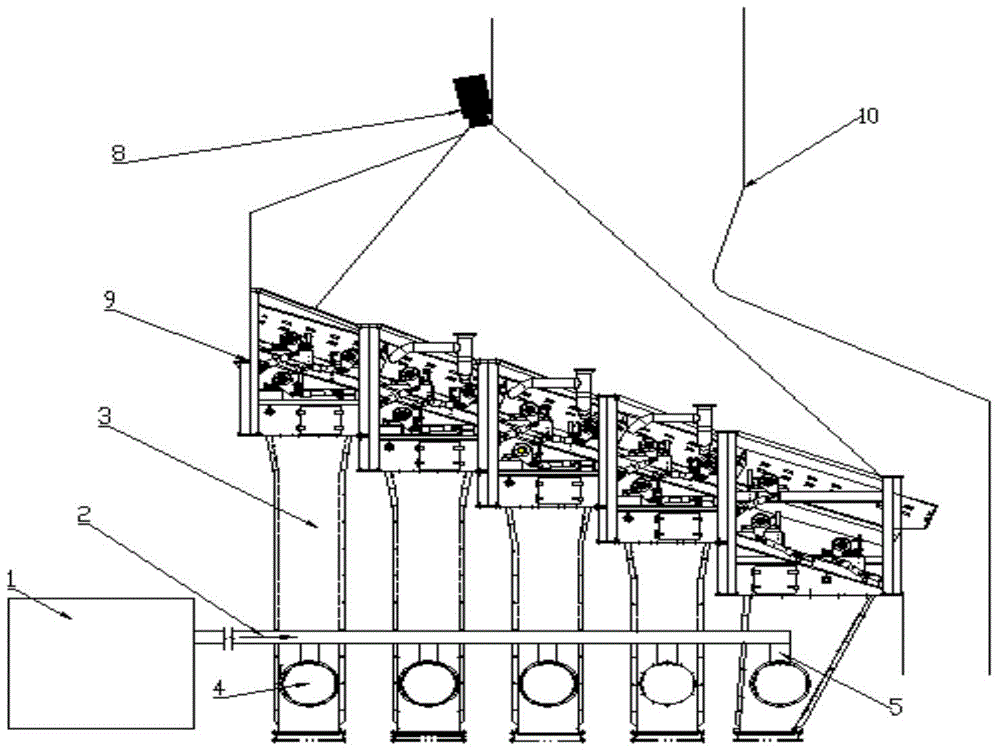

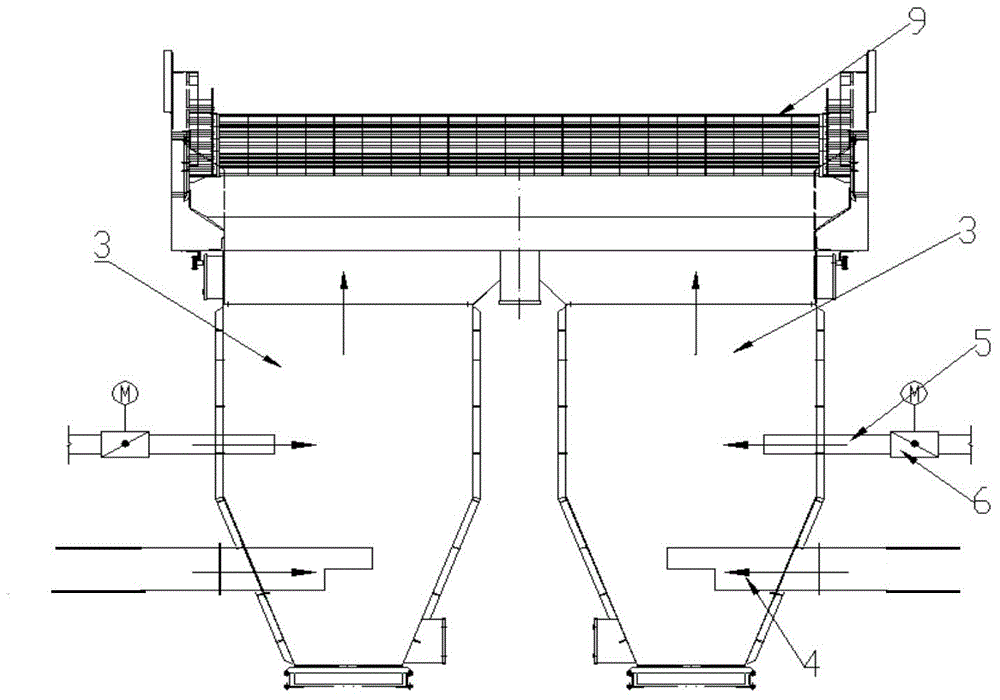

[0036] The invention provides a garbage incinerator, such as figure 2 As shown, the garbage incinerator of the present invention includes an oxygen generator 1, an oxygen air duct 2, an air chamber 3, a primary air inlet duct 4, an oxygen intake duct 5, an electric damper 6, a deflector 7, a camera 8, an incinerator Furnace 9 and hearth 10.

[0037] The garbage incinerator of the present invention will be further described below in conjunction with the accompanying drawings. The garbage incinerator of the present invention is zoned oxygen-enriched combustion, so that the garbage can be burned evenly on the grate, and the garbage can be fully burned, so that the garbage can be fully utilized. The thermal energy of the garbage can reduce the heat loss rate. In order to achieve the above purpose, the garbage incinerator of the present invention includes several independent air chambers located below the grate piece, and each independent air chamber is provided with The primary ...

Embodiment 2

[0054] The present invention also provides an incineration method of the garbage incinerator based on Embodiment 1, the method includes step S1: monitoring the flame position inside the garbage incinerator, and determining the grate pieces with uneven combustion conditions , and record and feed back the position of the air chamber corresponding to the grate piece;

[0055] Step S2: Open the electric damper of the oxygen intake pipe on the corresponding air chamber to increase the oxygen supply and improve the combustion condition.

[0056] Specifically, such as figure 2 , image 3 As shown, when uneven combustion occurs on the surface of the incinerator 9, when the flame does not spread to one or more areas on the incinerator with garbage material layers, or when it is necessary to increase the combustion effect of the material layer in one or more areas , the camera 8 records and feeds back the position of the oxygen content adjustment unit corresponding to the area. At th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com