Continuous ultrafine glass fibre and centrifugation manufacturing method thereof

A technology of ultra-fine glass fiber and glass fiber, which is applied in the field of continuous ultra-fine glass fiber, glass fiber, and centrifugal manufacturing of continuous ultra-fine glass fiber. It can solve the problems of producing continuous glass microfiber, achieve stable temperature, easy reaction process, Guaranteed continuity of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation method of the chopped continuous ultra-fine glass fiber that present embodiment centrifugation method comprises the following steps:

[0024] 1) In terms of mass, select 10 parts of borax, 41 parts of quartz sand, 8 parts of potassium feldspar powder, 5 parts of albite powder, 12 parts of dolomite, 19 parts of soda ash, and 2 parts of calcite;

[0025] 2) Heat the raw materials selected in step 1) to 1480°C to obtain molten glass;

[0026] 3) Grind with water abrasives to make the inner wall of the small hole of the centrifugal disc smooth, introduce the glass liquid in step 2) into the centrifugal plate with a rotation speed of 4000r / min, and the glass liquid is sprayed out from the small hole on the side wall of the centrifugal plate to form a fine glass flow; control the centrifugal During the process, the temperature of the molten glass in the centrifugal disc is 1300°C; the side wall of the centrifugal disc used in this embodiment is provided with 1...

Embodiment 2

[0032] The preparation method of the chopped continuous ultra-fine glass fiber that present embodiment centrifugation method comprises the following steps:

[0033] 1) By mass, select 8 parts of borax, 42 parts of quartz sand, 7 parts of potassium feldspar powder, 6 parts of albite powder, 11 parts of dolomite, 20 parts of soda ash, and 1 part of calcite;

[0034] 2) Heat the raw materials selected in step 1) to 1500°C to obtain molten glass;

[0035] 3) Grind with water abrasives to make the inner wall of the small hole of the centrifugal disc smooth, and introduce the glass liquid in step 2) into the centrifugal plate with a rotating speed of 3800r / min, and the glass liquid is sprayed out from the small hole on the side wall of the centrifugal plate to form a fine glass flow; control the centrifugal During the process, the temperature of the molten glass in the centrifugal disc is 1480°C; the side wall of the centrifugal disc used in this embodiment is provided with 8,000 sm...

Embodiment 3

[0041] The preparation method of the chopped continuous ultra-fine glass fiber that present embodiment centrifugation method comprises the following steps:

[0042] 1) In terms of mass, select 12 parts of borax, 40 parts of quartz sand, 9 parts of potassium feldspar powder, 4 parts of albite powder, 13 parts of dolomite, 18 parts of soda ash, and 3 parts of calcite;

[0043] 2) Heat the raw materials selected in step 1) to 1460°C to obtain molten glass;

[0044]3) Grind with water abrasives to make the inner wall of the small hole of the centrifugal disc smooth, introduce the glass liquid in step 2) into the centrifugal plate with a rotation speed of 4500r / min, and the glass liquid is sprayed out from the small hole on the side wall of the centrifugal plate to form a fine glass flow; control the centrifugal During the process, the temperature of the molten glass in the centrifugal disc is 1200°C; the side wall of the centrifugal disc used in this embodiment is provided with 15...

PUM

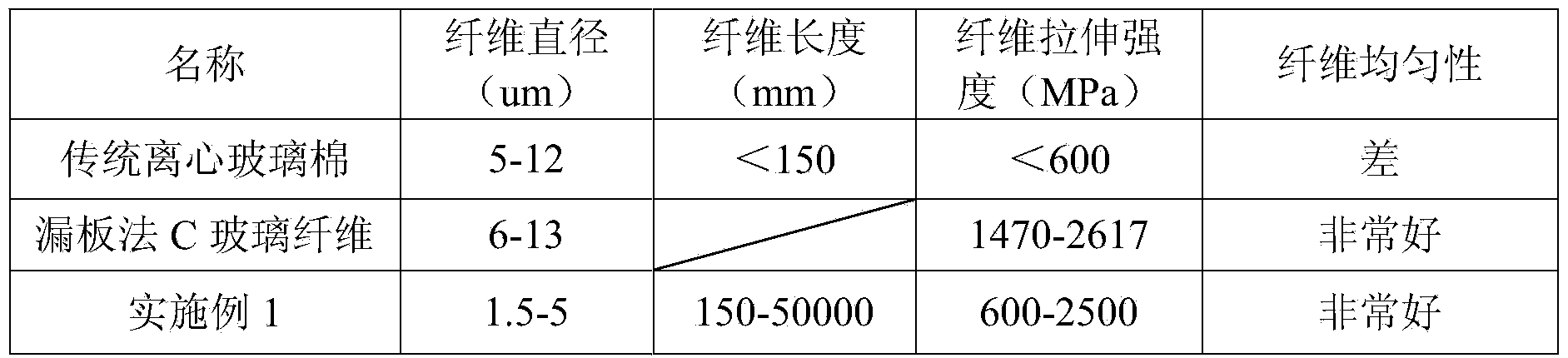

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com