A Biomass Combustion Furnace with Steady Feed Wind and Less Sparks

A biomass burning furnace, stable technology, applied in household stoves/stoves, solid heating fuel, lighting and heating equipment, etc., can solve the problems of uneven heating of cooking pots, large differences in flue pressure, etc., and achieve dust emission and pollutant reduction, good environmental performance, and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

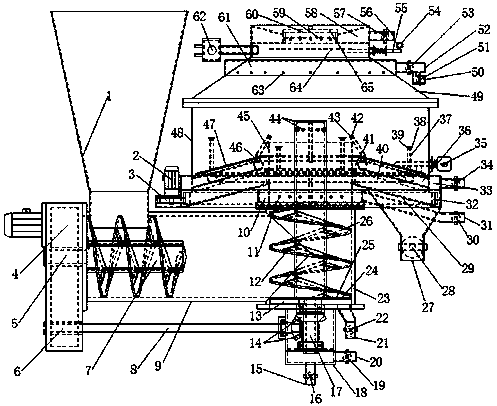

[0039] The upper end of the vertical feeding pipe 23 is connected with the lower end of the furnace feeding pipe 45 , and the lower end of the vertical feeding pipe 23 is connected with the vertical spiral support 18 . The side of vertical feed pipe 23 has feed inlet and is connected with horizontal feed pipe 9, and the other port of horizontal feed pipe 9 is connected with gearbox 4, and the end is connected with funnel 1 upwards.

[0040] The horizontal screw 7 is connected to the A output end 5, and the spiral body of the horizontal screw 7 is located below the funnel mouth of the funnel 1. Therefore, the horizontal screw 7 is rotationally connected with the horizontal feed pipe 9 through the A output end 5, and driven by the A output end 5 Lower horizontal feeding.

[0041]The B output end 6 of the gearbox is connected with one end of the transmission shaft 8, and the vertical spiral support 18 is provided with a bevel gear set 14, and the other end of the transmission sha...

Embodiment 2

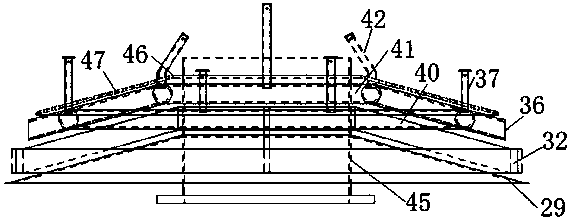

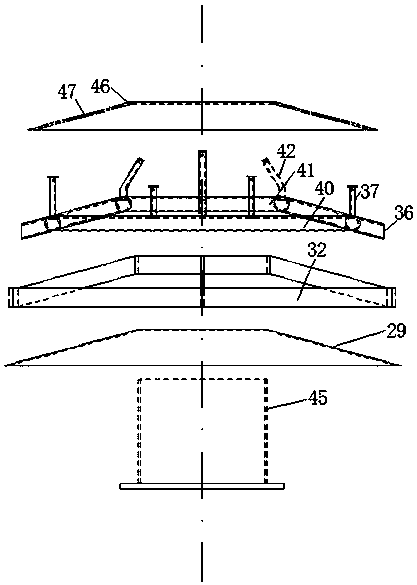

[0064] The upper furnace hearth 249 of the open shape is a round frustum annular structure, and the opening of the upper furnace hearth 249 of the open shape is a pot shape, and the upper port of the furnace hearth 48 is connected with the bottom port of the upper furnace hearth 249 of the open shape, and the bottom of the upper furnace hearth 249 of the open shape is provided with an ignition air outlet. Band 61; the upper and lower inner circles of the ignition wind belt 61 are connected with the bottom outer wall of the open-shaped upper furnace 249, and the bottom of the open-shaped upper furnace 249 is evenly opened on the same circumference with respect to the position of the ignition wind belt 61. Hole 63.

[0065] One end of the ignition gas valve 51 is connected with the ignition air inlet pipe 52, and the other end is the ignition gas inlet 50. One end of ignition air belt valve 53 is connected with ignition air inlet pipe 52, and the other end is connected with igni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com