Stove flue gas collection device and biomass burning furnace

A biomass combustion furnace and ash discharge device technology, applied in the field of combustion furnaces, can solve the problems of large difference in flue pressure, uneven heating of cooking pots, etc., and achieve good environmental protection performance, stable work, and reduced dust emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

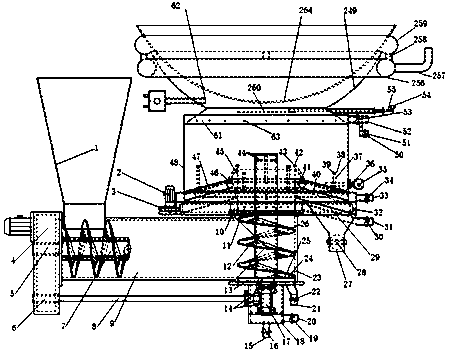

[0030]The upper end of the vertical feed pipe 23 is connected with the lower end of the furnace feed pipe 45, and the lower end of the vertical feed pipe 23 is connected with the vertical spiral support 18. The side of the vertical feed pipe 23 has a feed inlet and is connected with the horizontal feed pipe 9, and the other end of the horizontal feed pipe 9 is connected with the gearbox 4 and the funnel 1 respectively. The horizontal screw 7 is connected with the A output end 5 of the gearbox, and the horizontal screw 7 is flexibly connected with the horizontal feed pipe 9 . One end of the transmission shaft 8 is connected with the B output end 6 of the gearbox, and the other end is connected with one of the bevel gear sets 14, and the other end of the bevel gear set 14 is connected with the lower end of the vertical helix 26, and the transmission shaft 8 is connected with the vertical helix Bearing 18 is flexibly connected. One end of the chip removal valve B 16 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com