Injection type metal burning torch

A shooting-suction cutting gun technology, applied in the field of cutting guns, can solve the problems of personal injury of operators, affecting the use effect of cutting guns, and rising cost of cutting guns, so as to achieve good temperature control, reduce replacement frequency, and improve the use effect Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

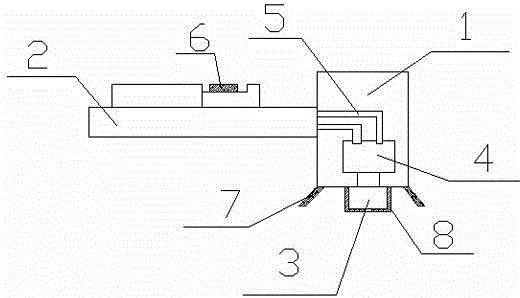

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

[0011] An injection-suction metal torch, comprising a torch head 1 and a torch handle 2, the torch head 1 is rectangular, the torch head 1 and the torch handle 2 are connected to each other, and a nozzle 3 is arranged under the torch head 1, The nozzle 3 is a cylindrical nozzle. The nozzle 3 is connected with an air mixing part 4. The air mixing part 4 is a mixing chamber. There is a scale adjustment file, and a shielding part 7 is arranged around the nozzle 3. The shielding part 7 is made of hard resin material, and the shielding part 7 is coated with a strong light shielding film. The heads 1 are connected to each other, the shielding part 7 is connected to the torch head at an oblique angle, and the nozzle 3 is provided with a high temperature resistant coating 8, which is a quartz coating, and the thickness of the high temperature resistant coating 8 is 5 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com