Gas heating type industrial vertical kiln with central burner

A combustion device and gas heating technology, applied in the field of gas heating furnaces and kilns, can solve the problems of inability to burn through the calcined products, reduce the quality of the calcined products, and over-burn the calcined products, so as to reduce maintenance costs, improve the utilization rate of equipment, prolong the The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

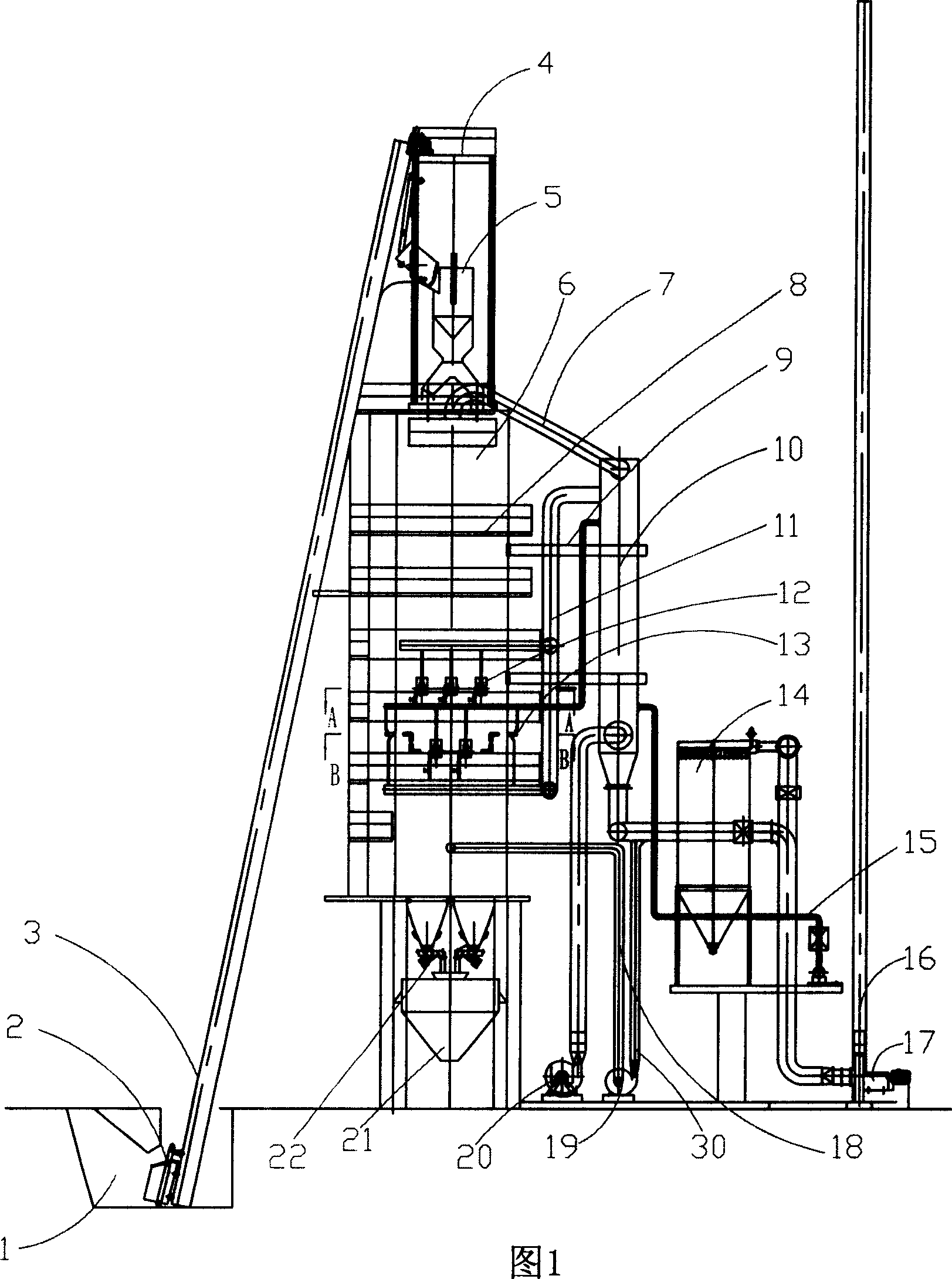

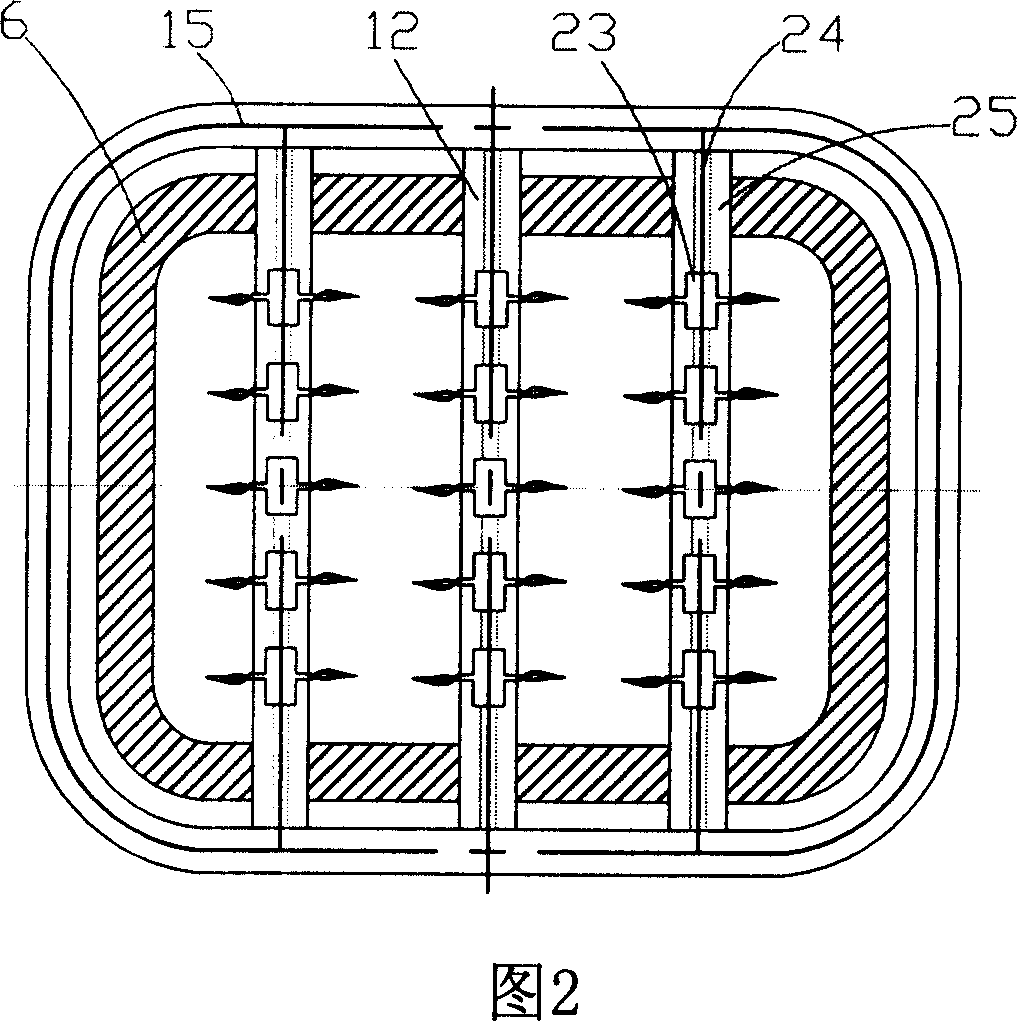

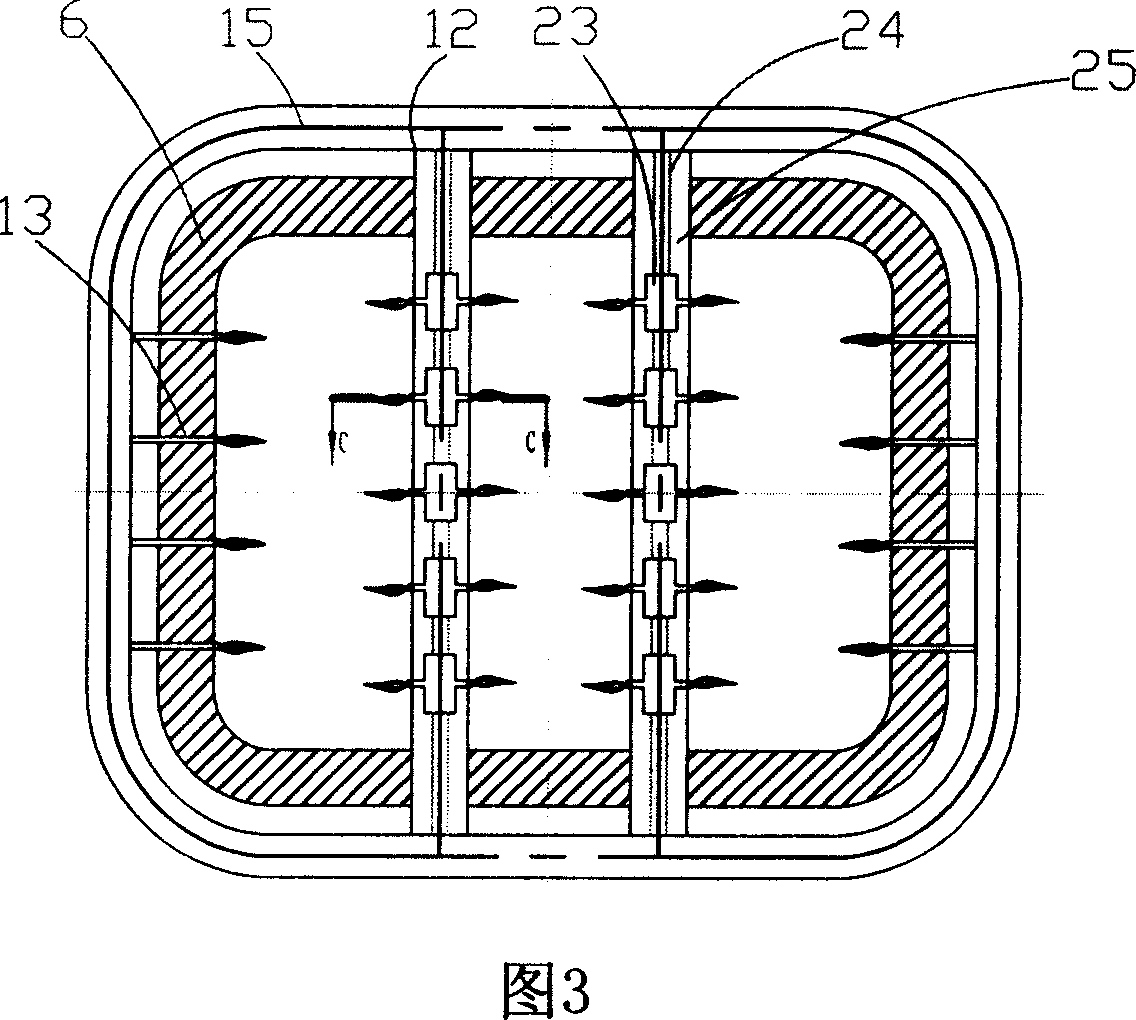

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] As shown in the figure, in the embodiment of the gas-heated industrial shaft kiln with a central combustion device involved in the present invention, it includes a kiln body, a feeding device, a fuel delivery device, a discharge device, a smoke exhaust device, and a combustion device Composition; the kiln body is a shaft kiln 6, a platform 8 is arranged on the top of the shaft kiln 6, a support 9 is arranged on its side, and a heat exchanger 10 is fixed on the support 9; the feeding device includes a pit 1, Feeding car 2, inclined bridge 3, feeding device support 4 and feeding device 5; said discharging device includes discharging car 21, electromagnetic vibration discharging machine 22; described smoke exhaust device includes dust collector 14, smoke exhaust fan 17, Exhaust gas pipeline 7, chimney 16, induced draft pipe 18, negative induced draft fan 19; Descri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com