Lower air inlet gas burner for cooking appliance

A gas burner and cooker technology, which is applied in the field of integrated cookers, can solve the problems of unreasonable setting of fire hole parameters of the fire cover, impossibility of finishing, and high resistance of internal fire ejection, so as to improve the ejection effect and good flame appearance , flame clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

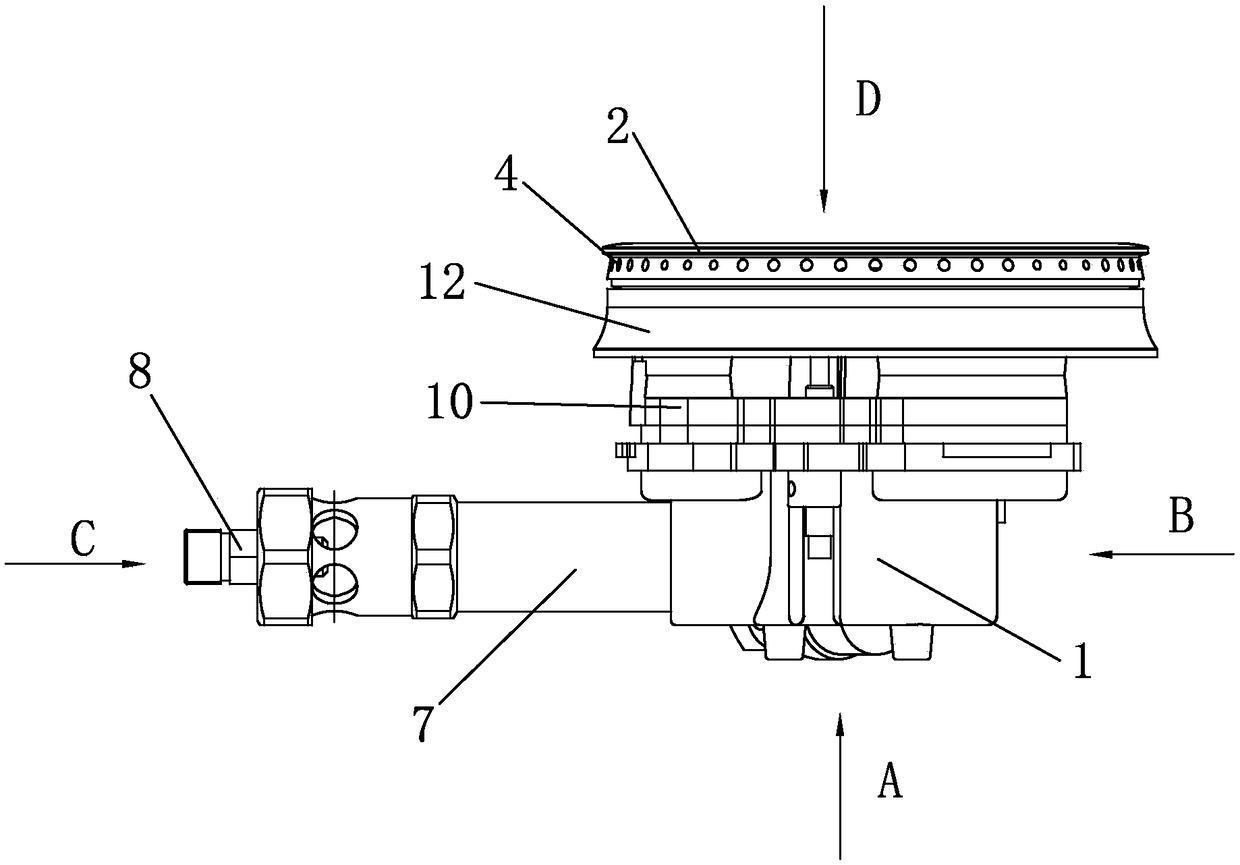

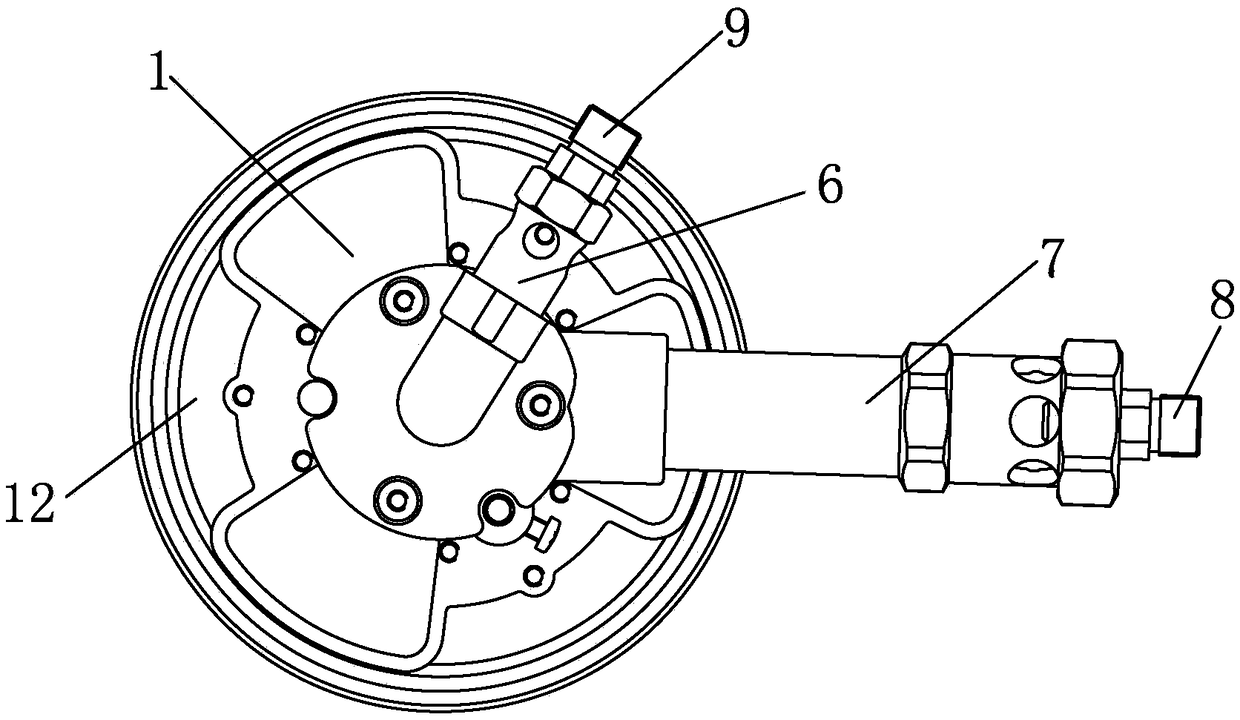

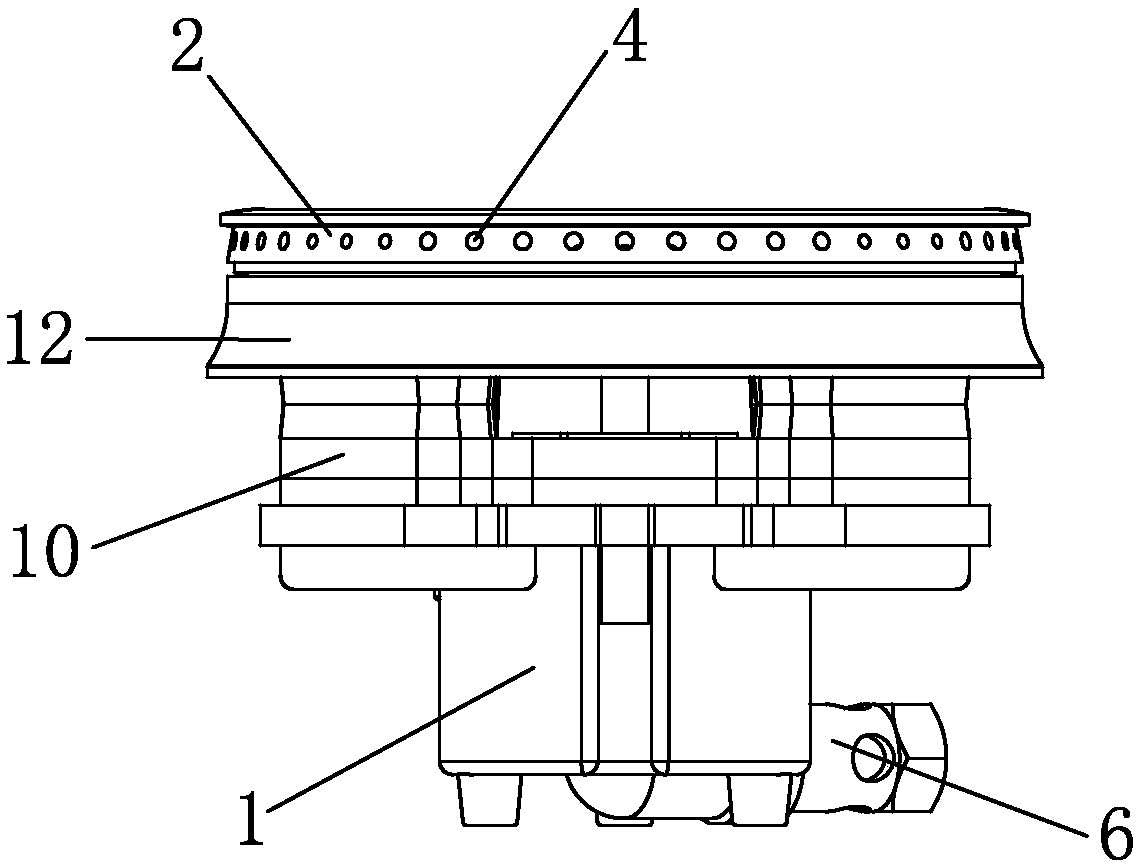

[0027] Such as Figure 1 to Figure 9 As shown, it is the gas burner with the lower air intake for the cooker of the present invention, including a base 1 and a fire cover, the fire cover includes an outer fire cover 2 and an inner fire cover 3, and the outer fire cover 2 is provided with an outer fire hole 4, The inner fire cover 3 is provided with the inner fire hole 5, and the outer fire cover 2 and the inner fire cover 3 are all arranged on the base 1, and the base 1 is provided with an ejector tube, and the ejector tube includes the inner fire injector tube 6 and the inner fire cover 3. Outer fire ejection pipe 7, outer fire ejection pipe 7 is provided with outer fire nozzle 8, inner fire ejection pipe 6 is provided with inner fire nozzle 9, base 1 and ejection pipe are split structures, ejection pipe and base 1 Threaded connection, the base 1 is made of aluminum die-casting technology, and the injection tube is made of mechanical processing technology to realize the finis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com