A heating furnace based on honeycomb ceramic regenerator

A technology of honeycomb ceramics and regenerators, which is applied to furnaces/stoves with hot water devices, heating methods, household heating, etc. It can solve the problems of large smoke and dust emissions, insufficient fuel combustion, etc., and achieve NOx Less generation, sufficient combustion, and good combustion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

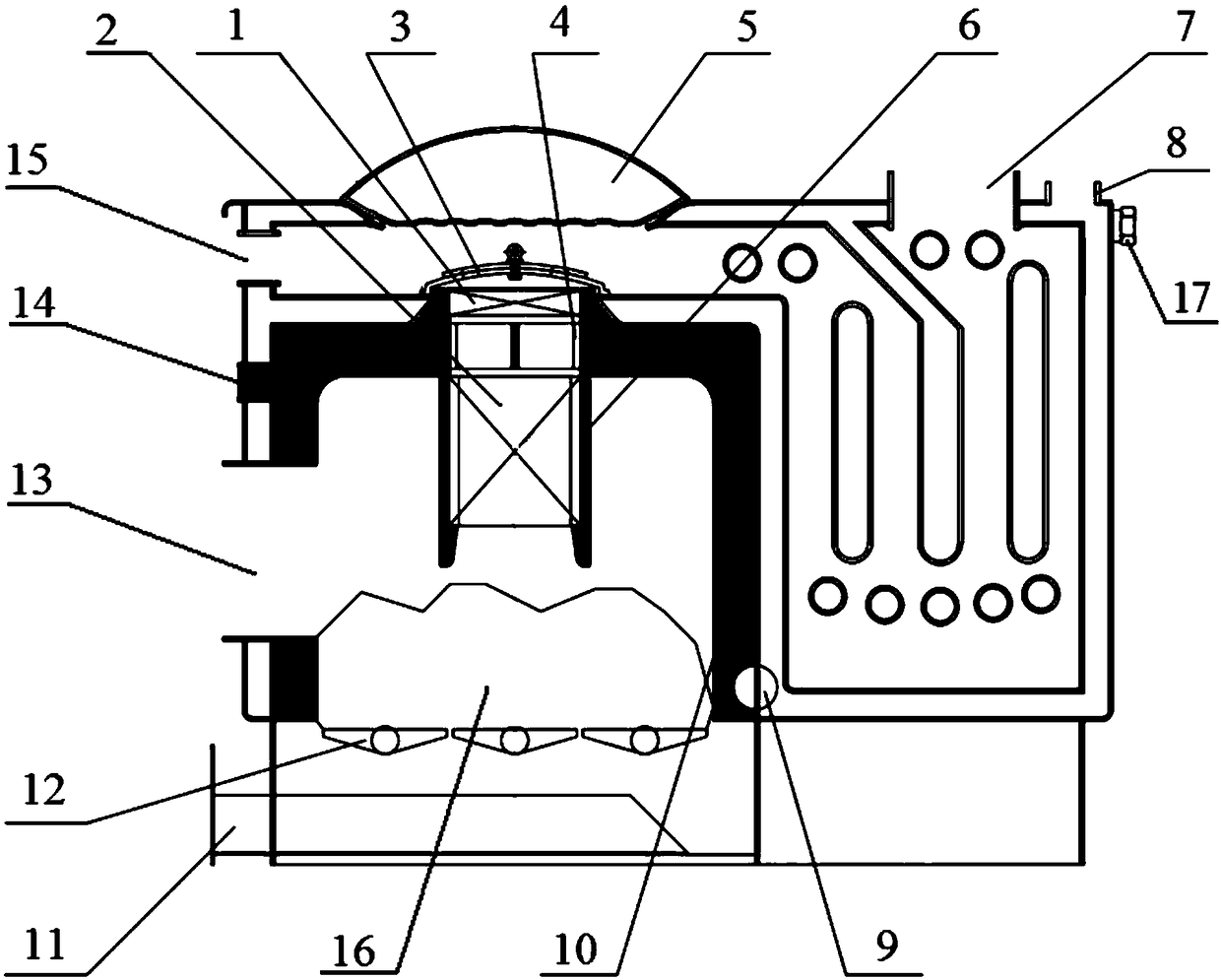

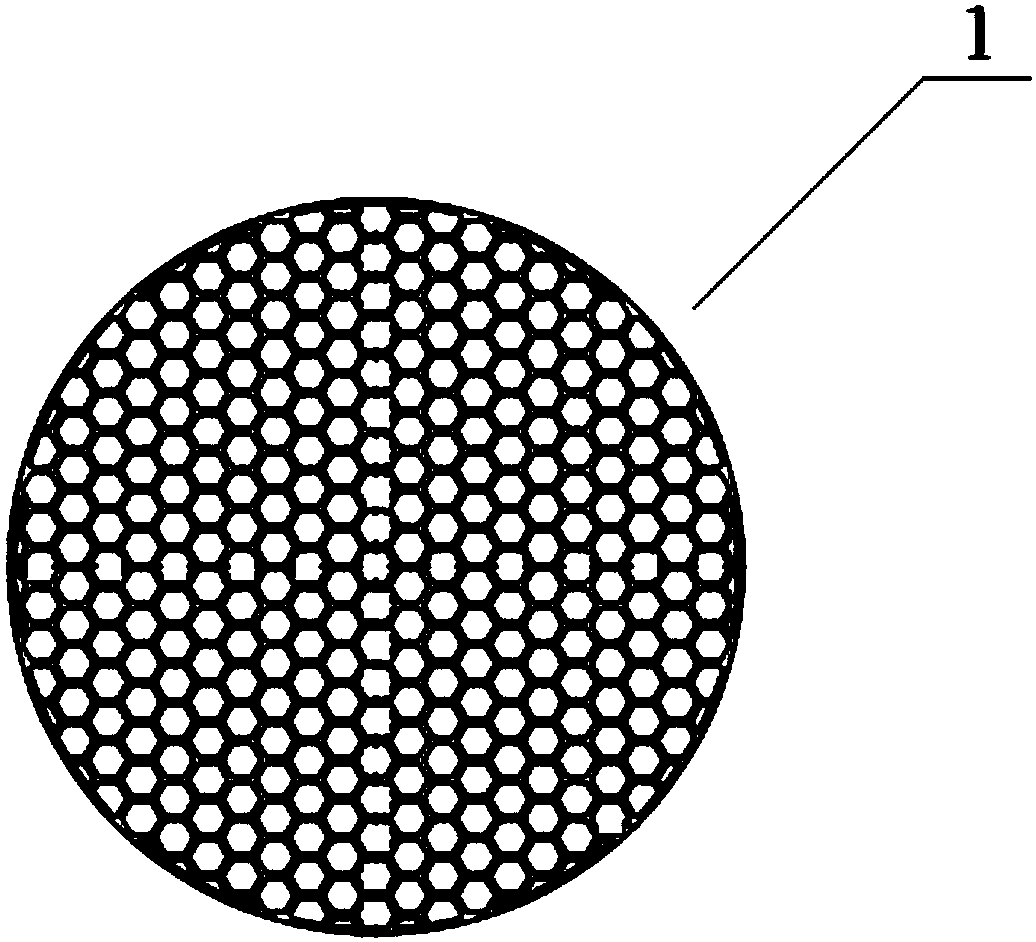

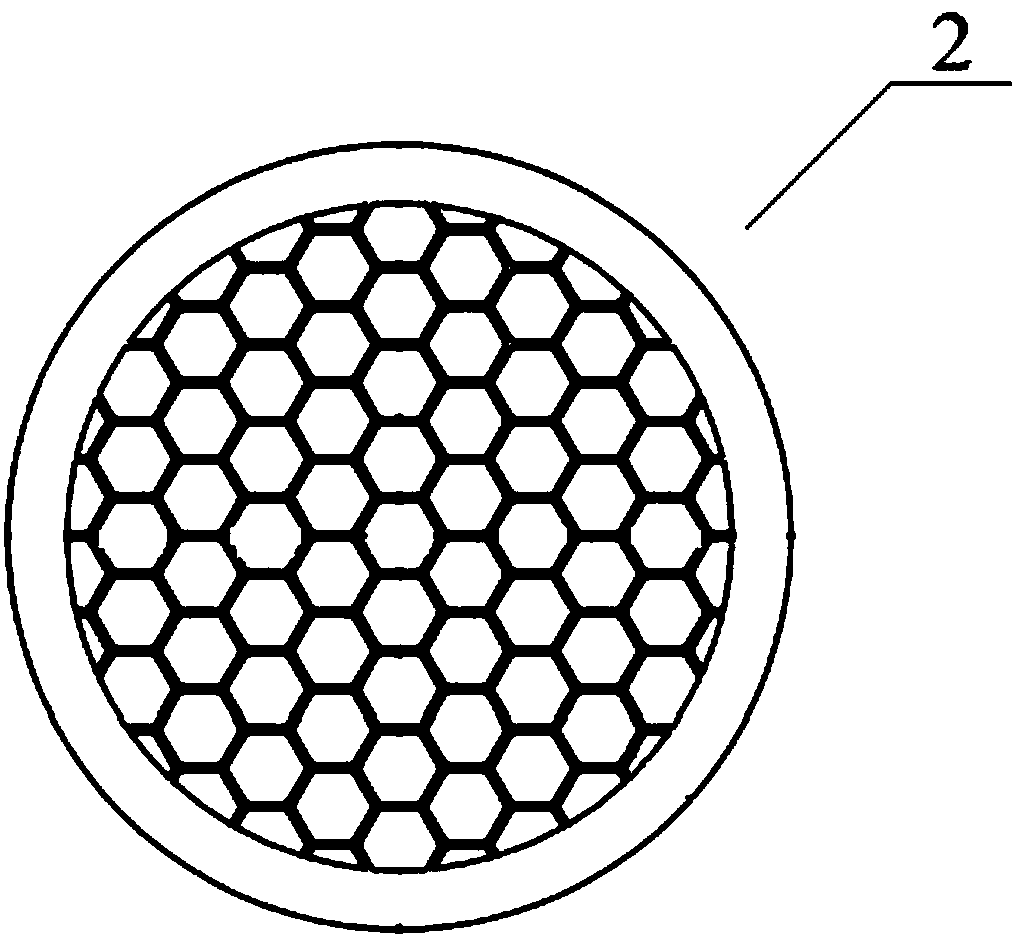

[0036] Such as Figure 1-Figure 3 As shown, a heating furnace based on a honeycomb ceramic regenerator includes a furnace body, a furnace chamber is provided inside the furnace body, a fire outlet is provided at the upper end of the furnace chamber, and a sheath is embedded in the fire outlet The sleeve 6, the sheath sleeve 6 is a cylindrical shape with upper and lower openings, and the first honeycomb ceramic regenerator 1 and the second honeycomb ceramic regenerator 2 are embedded in the sheath sleeve 6, and the first honeycomb ceramic regenerator The regenerator 1 is located above the second honeycomb ceramic regenerator 2, and the first honeycomb ceramic regenerator 1 and the second honeycomb ceramic regenerator 2 are separated by a support body 4 to form a secondary combustion chamber. Both the first honeycomb ceramic regenerator 1 and the second honeycomb ceramic regenerator 2 have several vertically arranged through holes, and the cross-sectional area of the through h...

Embodiment 2

[0049] In this embodiment, the hole patterns of the through holes of the first honeycomb ceramic heat storage body 1 and the hole shape of the first honeycomb ceramic heat storage body 2 are both regular quadrilaterals.

[0050] Such as Figure 4 As shown, the heating cover 5 is a container-type circular arched heating cover, the middle of the top of the heating cover 5 is connected through a pipe to the side of the heating water supply pipe, and the side of the heating cover 5 is passed through another One pipe is connected through to the side of the heating return pipe; one end of the heating water supply pipe is connected to the water outlet 8 of the circulating water tank in the furnace body, and the other end is connected to the water inlet end of the radiator; one end of the heating return pipe is connected to the furnace body The water tank return port 9 of the circulating water tank, the other end is connected to the return water end of the radiator; the heating cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com