Dust fuel burners and entrained bed gasifiers for synthesis gas production

A synthesis gas and burner technology, which is applied in the direction of burning powder fuel burners, granular/powder fuel gasification, burners, etc., can solve the problems of coal supply pipe wear and limit burner efficiency, and achieve distribution promotion, High repair and maintenance friendliness, high wear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

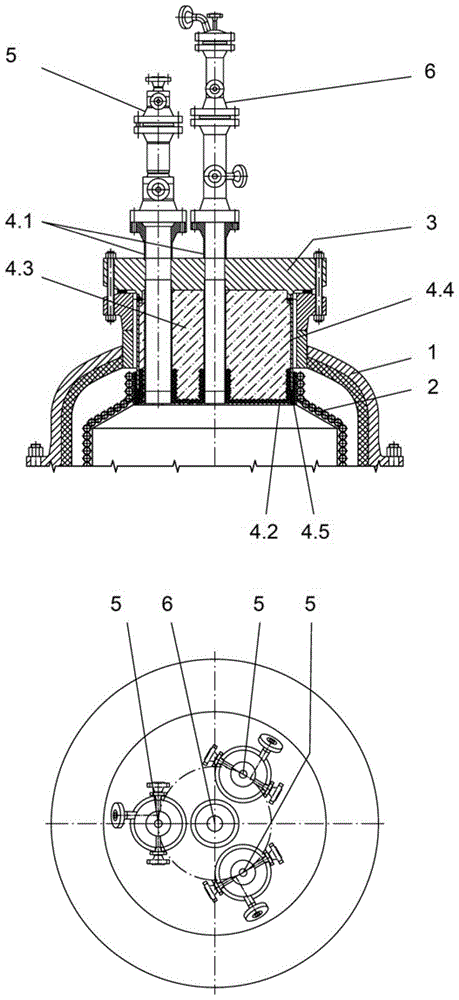

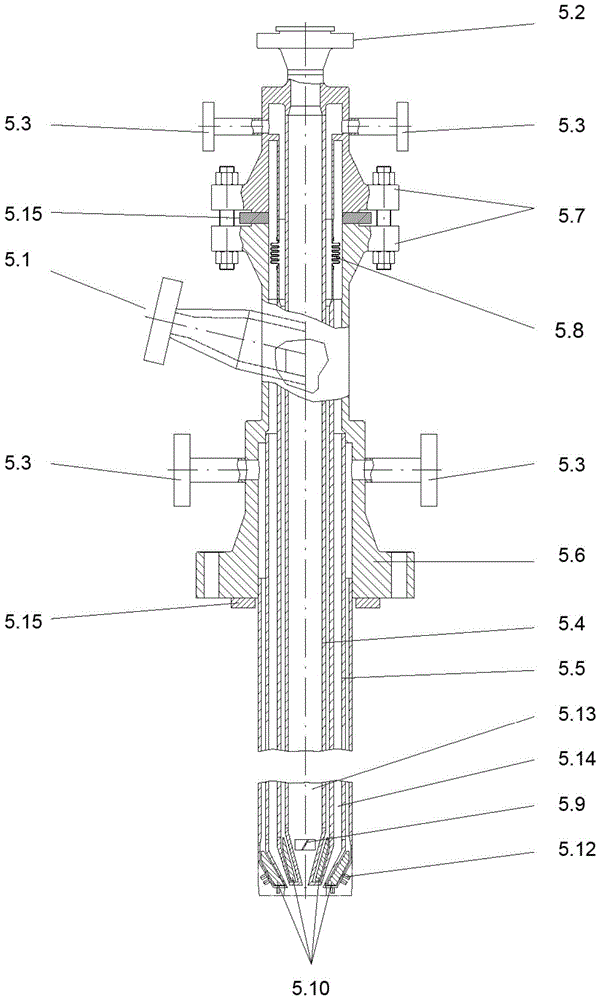

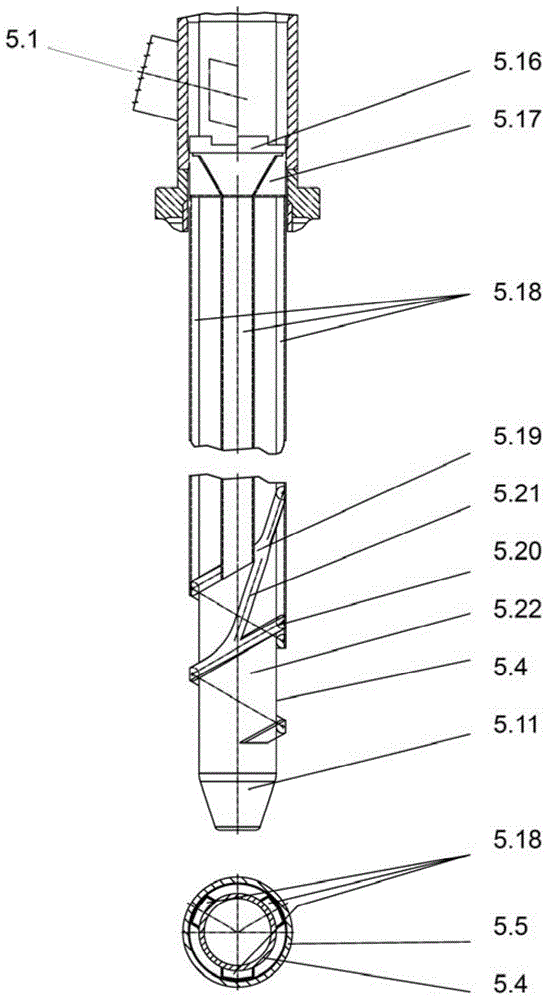

[0026]as from figure 1 It can be seen that a cover flange 3 closes upwardly and pressure-tightly the reaction chamber of an entrained-bed gasifier 1 . The inside of the cover flange 3 is thermally protected by a burner box 4 which closes an upper opening of a cooling barrier 2 . The cooling screen 2 is internally cooled with water and protects the pressure jacket of the entrained-bed gasifier 1 against heating and slag deposition.

[0027] The burner arrangement in the cover flange 3 consists of three centrosymmetrically distributed burners 5 for partial oxidation of pulverized coal (powdered coal burner, gasification burner) in a common cover The flange 3 is correspondingly arranged at an angle of 120° on the circumference around a central starter burner 6 . The cover flange 3 upwardly closes the gasifier interior in a pressure-tight manner and enables access to the gasifier interior for inspection or maintenance purposes.

[0028] The initial burners 6 are arranged vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com