Feeding equipment for producing polyethylene fibers

A polyethylene powder and feeding technology, which is applied in the direction of feeding the solution to the spinneret, etc., can solve the problems of high viscosity, clogging and difficult installation of the solution in the kettle, and achieve constant flow rate, avoid material accumulation and stable pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

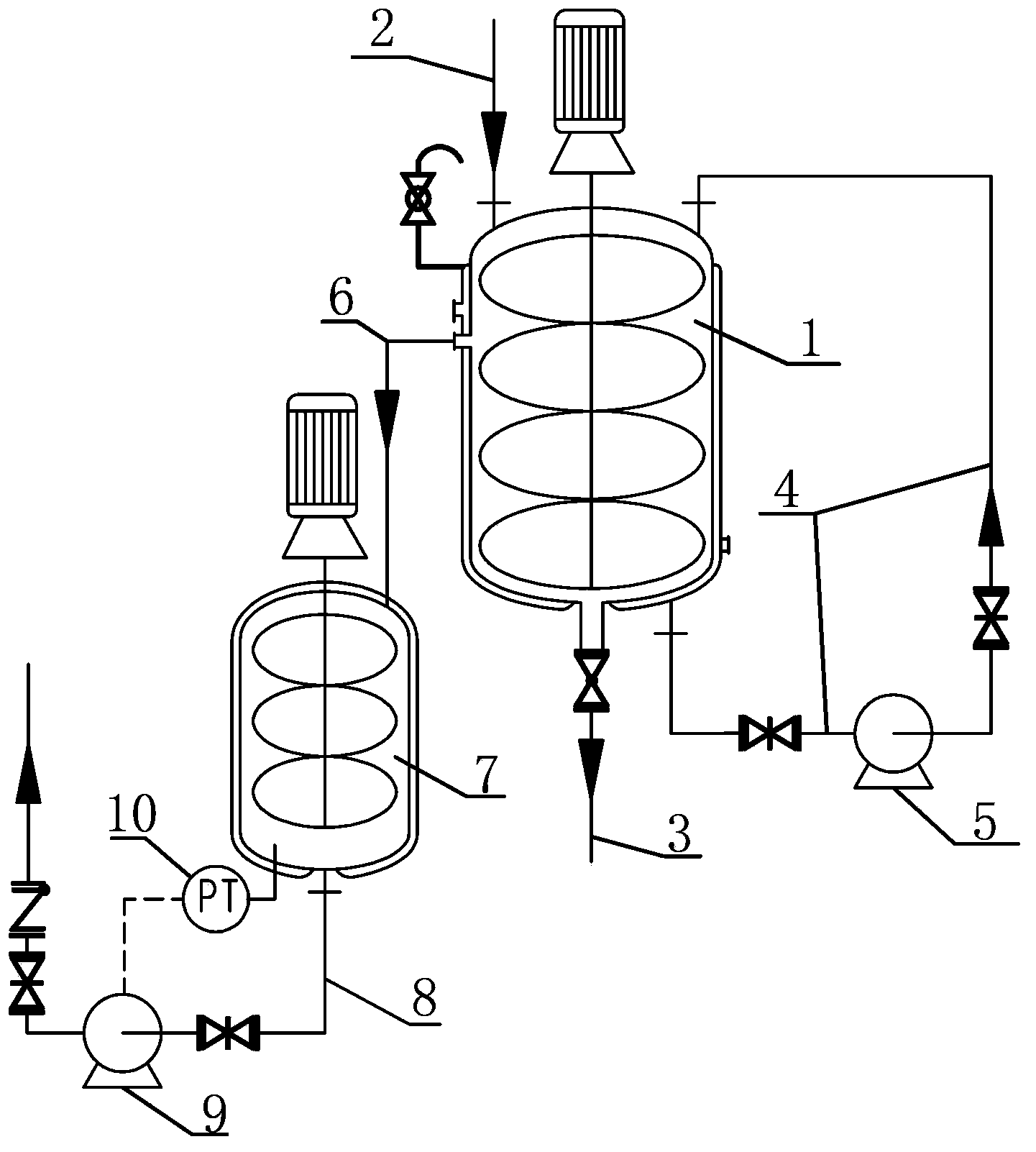

[0012] With reference to the attached drawings, a feeding equipment for the production of polyethylene fiber includes a feeding kettle 1, and a polyethylene powder and solvent mixture input pipeline 2 is connected to the top of the feeding kettle 1. The bottom is connected with a polyethylene powder and solvent mixture output pipeline 3. The feeding kettle 1 is also connected with a polyethylene powder and solvent mixture circulation pipe 4, the inlet end of the polyethylene powder and solvent mixture circulation pipe 4 is connected to the bottom of the feeding kettle 1, and the polyethylene powder and The outlet end of the solvent mixture circulation pipe 4 is connected to the feeding kettle 1. A circulation pump 5 is provided on the polyethylene powder and solvent mixture circulation pipe 4, and the material flows out from the bottom of the feeding kettle 1 through the circulation pump 5 , It enters from the top of the feeding kettle 1 to realize material circulation, which n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com