Conveying device capable of passively adjusting flow

A conveying device and flow rate technology, which is applied in the pipeline system, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of too many electrical components, too fast, manual control can not achieve more accurate and timely adjustment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

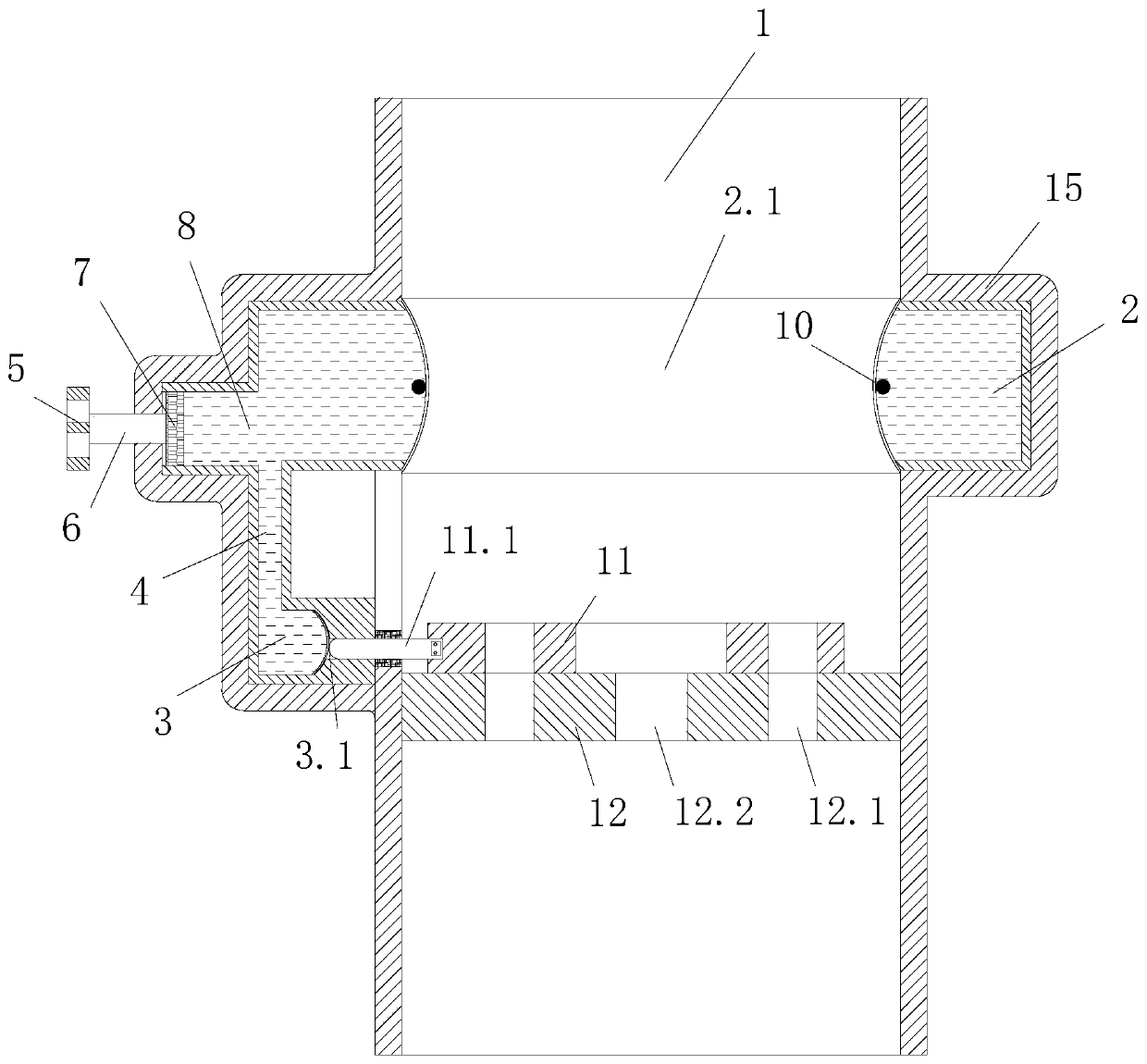

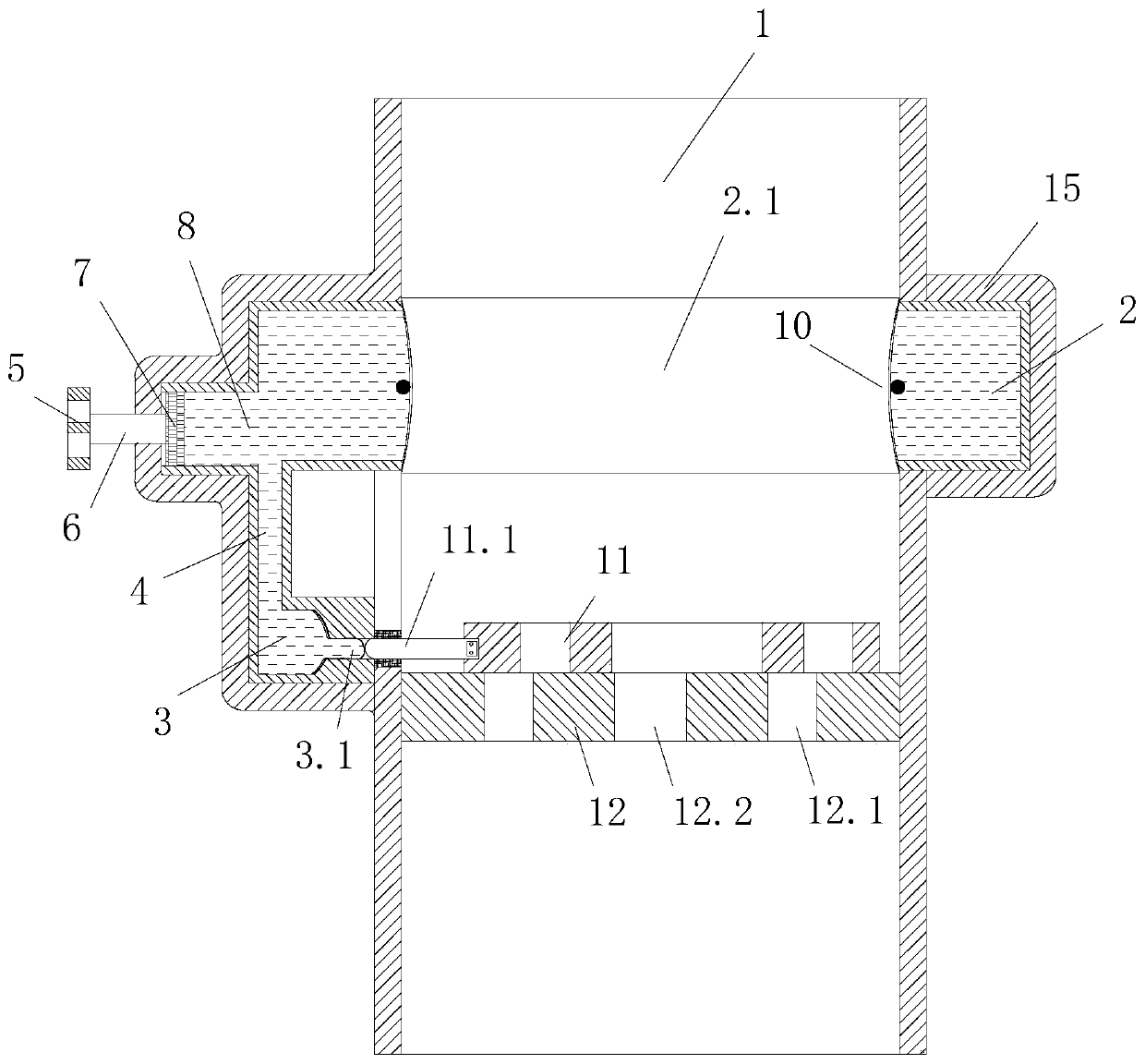

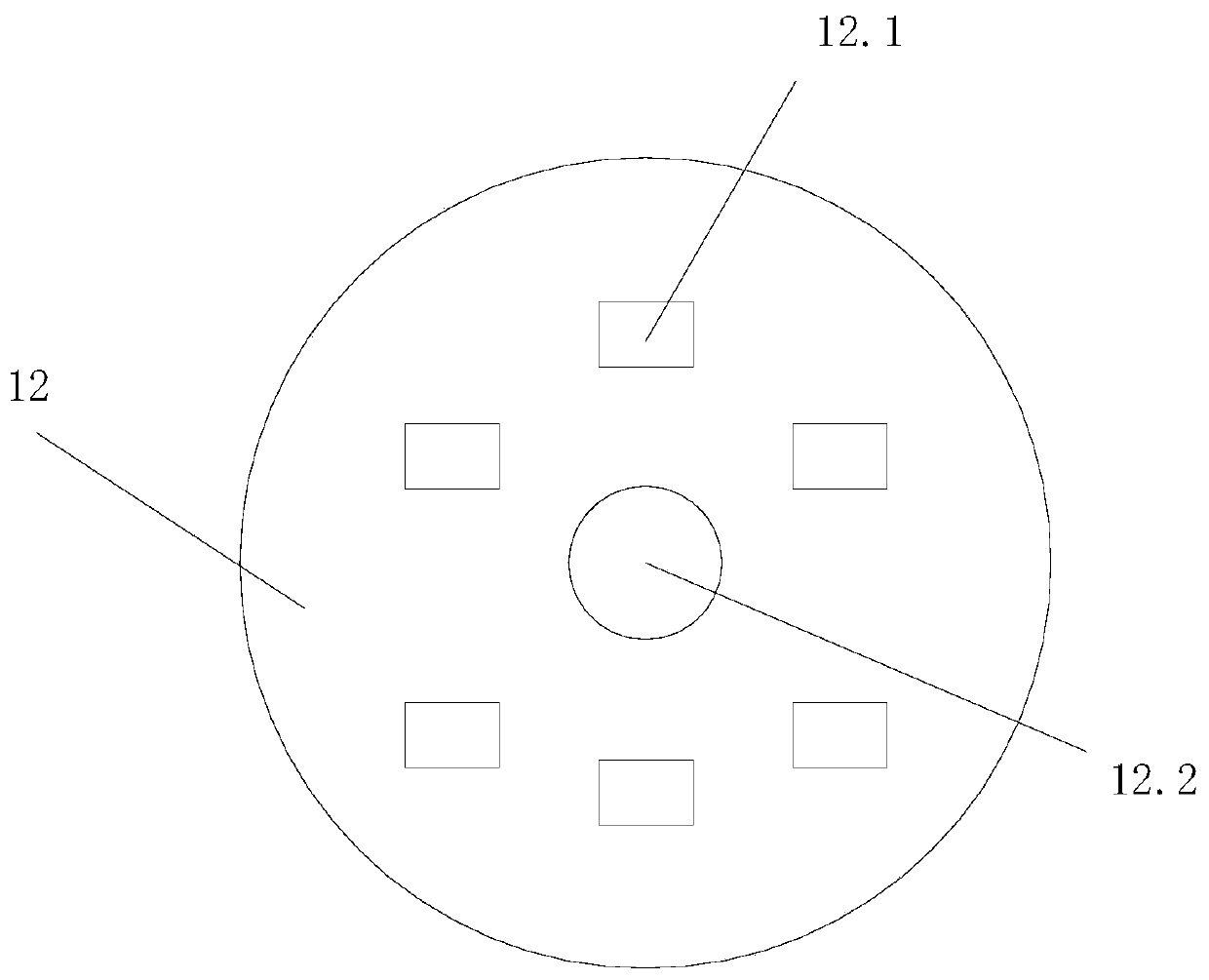

[0033] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0034] In each embodiment of the present invention, upstream and downstream are relative to the flow direction of fluid or gas, and the flow direction of fluid or gas is from upstream to downstream, while inside and outside are relative to pipeline 1, such as pipeline 1 inner and outer walls. The intermediate device provided by the present invention is mainly used for the regulation of pulsed liquid flow or air flow, and it can be used alone or in combination with flow rate or flow regulating devices such as automatic regulating valves in the prior art, so as to obtain better technical effects.

[0035] Such as Figure 1-10 As shown, a delivery device for passive flow adjustment provided by the embodiment of the present invention includes a pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com