Method for preparing p-cymene from dipentene

A technology for cymene and dipentene, applied in chemical instruments and methods, hydrocarbons, hydrocarbons, etc., can solve the problems of complex process and low cymene content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing p-cymene by dipentene, comprising the following steps:

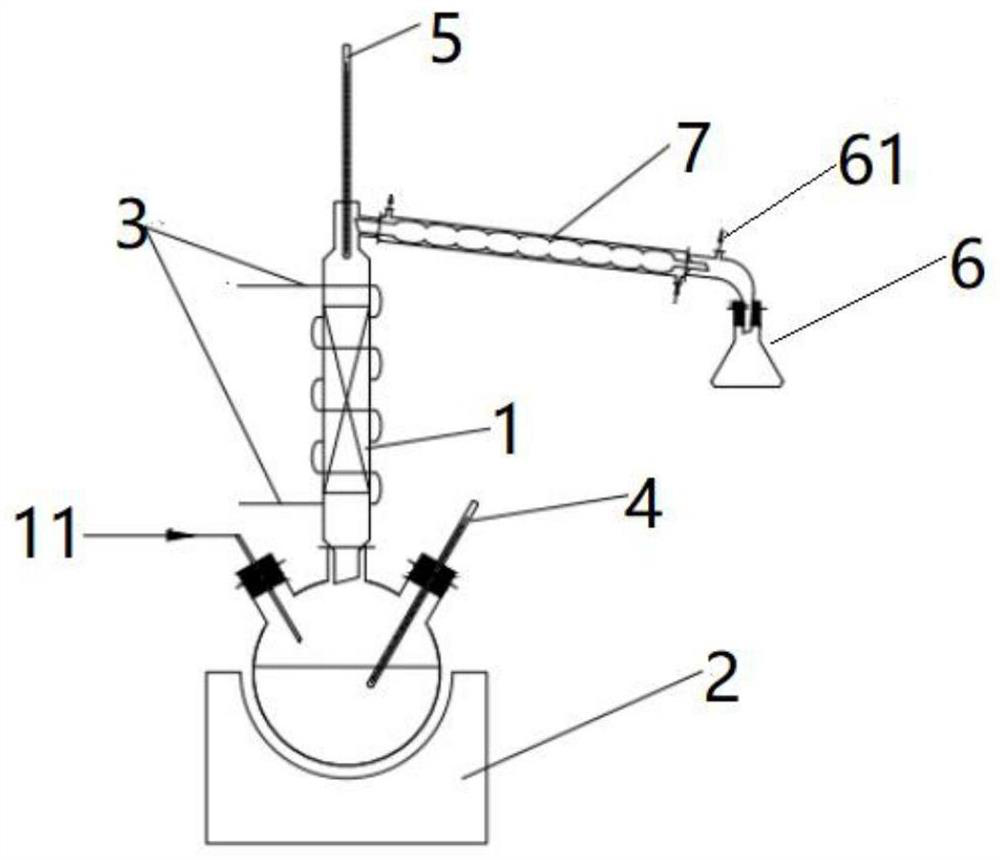

[0039] S1, mix powdery palladium carbon catalyst (mass content of palladium 5-7wt%) and stainless steel θ ring filler with a mass ratio of 1:1, naturally pack in a fixed-bed reactor whose body is a temperature-resistant glass tube, and assemble A good gas phase reaction device; nitrogen gas is introduced at a low speed to exhaust the air in the device and maintain continuous access;

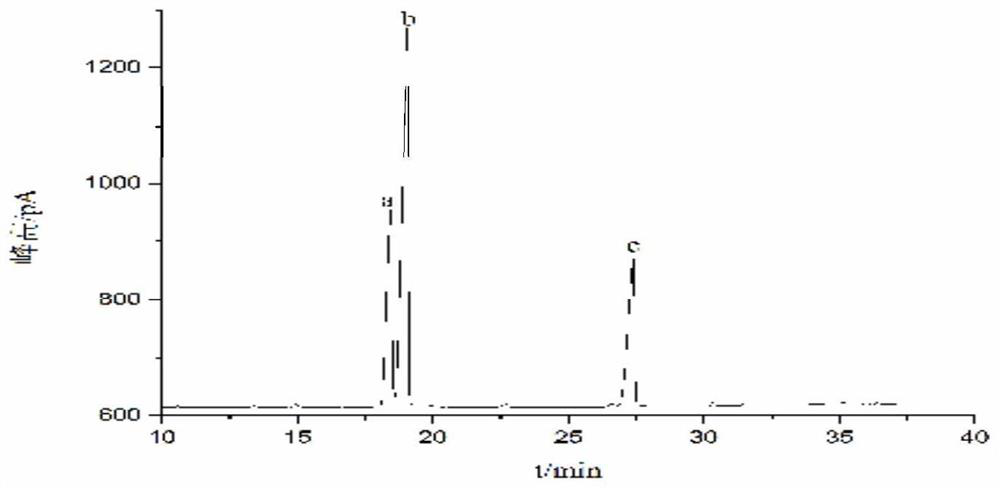

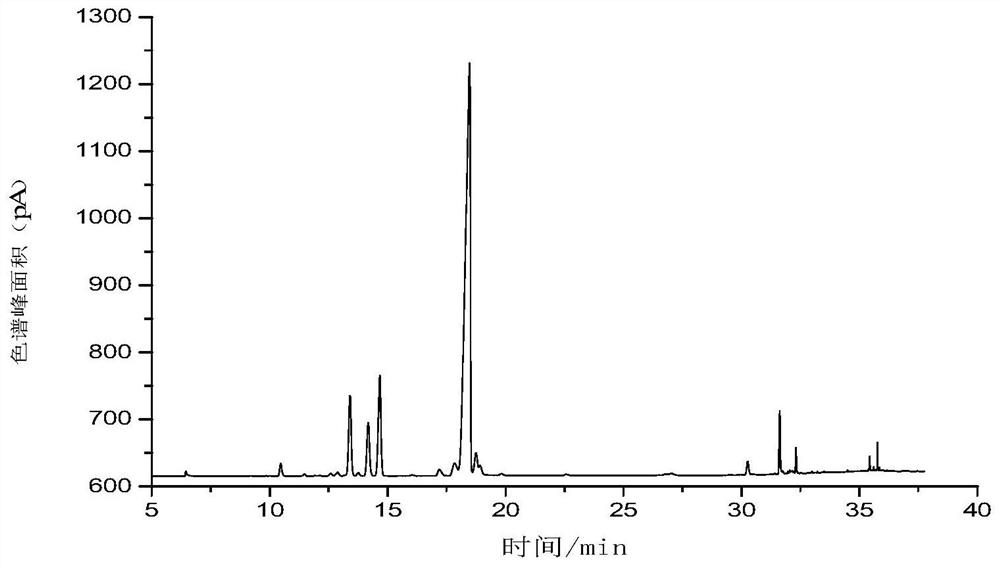

[0040] S2. Heating to bring the temperature inside the vaporizer to 200°C. The outer surface of the fixed-bed reactor is wound with an electric heating belt to heat the inside of the fixed-bed reactor to 180°C. Add industrial dipentene dropwise at a rate of 0.05mL / s. into the vaporizing bottle, and when steam reaches the top of the fixed-bed reactor, turn on the vacuum pump and maintain a vacuum degree of 0.09MPa inside the device, collect the liquid product, combine figure 2 and 3 , the content of p-cymene ...

Embodiment 2

[0044] A method for preparing p-cymene by dipentene, comprising the following steps:

[0045] S1, mix powdery palladium carbon catalyst (mass content of palladium 5-7wt%) and stainless steel θ ring filler with a mass ratio of 1:1, naturally pack in a fixed-bed reactor whose body is a temperature-resistant glass tube, and assemble A good gas phase reaction device; nitrogen gas is introduced at a low speed to exhaust the air in the device and maintain continuous access;

[0046] S2. Heating to bring the temperature inside the vaporizer to 180°C. The outer surface of the fixed bed reactor is wound with an electric heating belt to heat the fixed bed to 180°C. Add industrial dipentene dropwise to the vaporizer at a rate of 0.05mL / s. , when steam reaches the top of the fixed-bed reactor, turn on the vacuum pump and maintain the internal vacuum of the device at 0.09MPa, collect the liquid product, and analyze the content of p-cymene in the product by gas chromatography to be 92.14%. ...

Embodiment 3

[0048] A method for preparing p-cymene by dipentene, comprising the following steps:

[0049] S1, mix powdery palladium carbon catalyst (mass content of palladium 5-7wt%) and stainless steel θ ring filler with a mass ratio of 1:1, naturally pack in a fixed-bed reactor whose body is a temperature-resistant glass tube, and assemble A good gas phase reaction device; nitrogen gas is fed at a low speed to exhaust the air in the device and keep feeding continuously; it should be noted that the powdered palladium-carbon catalyst is a catalyst in which palladium is loaded on the carrier activated carbon.

[0050] S2. Heating to bring the temperature inside the vaporizer to 200°C. The outer surface of the fixed bed reactor is wound with an electric heating belt to heat the fixed bed to 180°C. Add industrial dipentene dropwise to the vaporizer at a rate of 0.1mL / s. , when steam reaches the top of the fixed-bed reactor, turn on the vacuum pump and maintain the internal vacuum of the devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com