Diesel locomotive static heating isolation heat exchange equipment

A technology of static heating and isolated heat exchange, which is applied in the direction of mechanical equipment, fuel heat treatment devices, engine components, etc., can solve the problems of high pollution, high fuel consumption, high cost, etc., and achieve improved reliability, low noise in equipment operation, and running smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

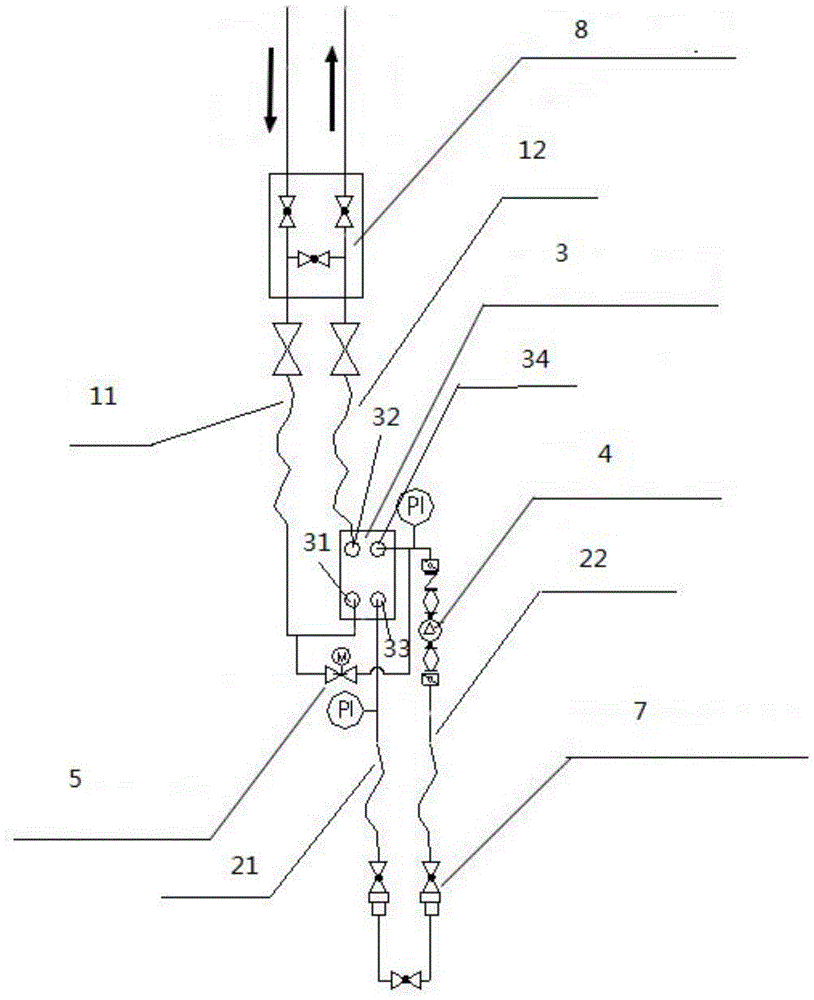

[0037] The present invention will be further described now in conjunction with accompanying drawing.

[0038] The water circulation system in the locomotive needs to be heated by an external ground heat source under static conditions such as standby or deactivation. In the present invention, the ground heat source is called the ground heating heat source main system, and the water circulation system in the locomotive is called the locomotive water system. The static heating isolation heat exchange equipment for a diesel locomotive of the present invention is connected between the ground heating heat source main system and the locomotive water system to realize functions such as heat exchange and water addition.

[0039] refer to figure 1 , in one embodiment, the static heating isolation heat exchange equipment for a diesel locomotive of the present invention includes: a heat exchange heat source pipeline, a locomotive heating pipeline, a heat exchanger 3, a circulation pump 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com