Electromagnetic plasma rotary processing device

A rotary processing device and plasma technology, applied in the field of ions, can solve the problems of complex contact drive structure, wear of the drive link, scratches on the product surface, etc., and achieve the effects of avoiding scratches on the product surface, uniform flame, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

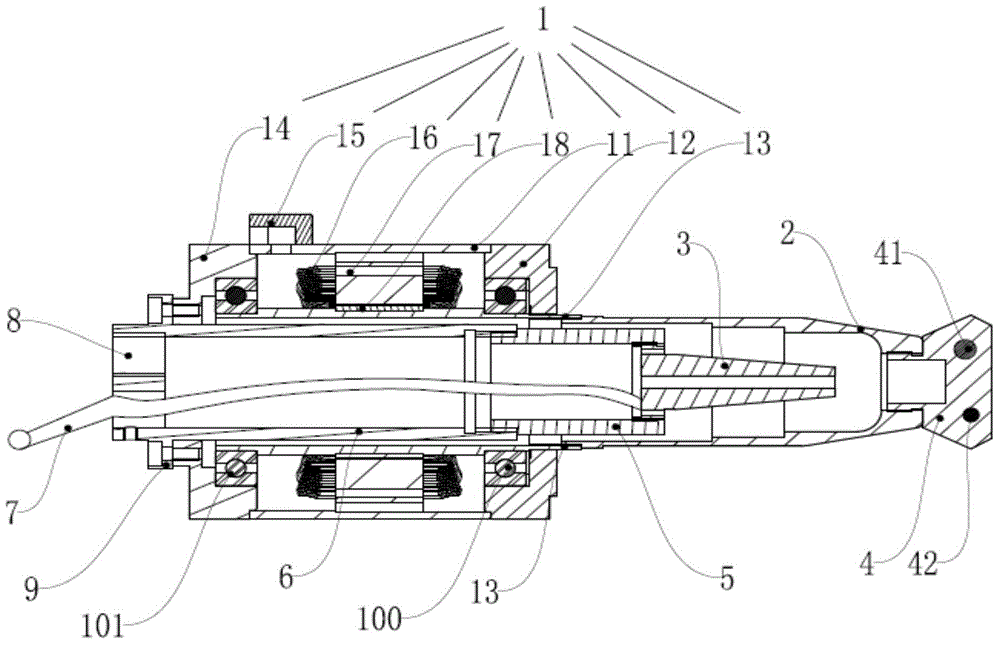

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

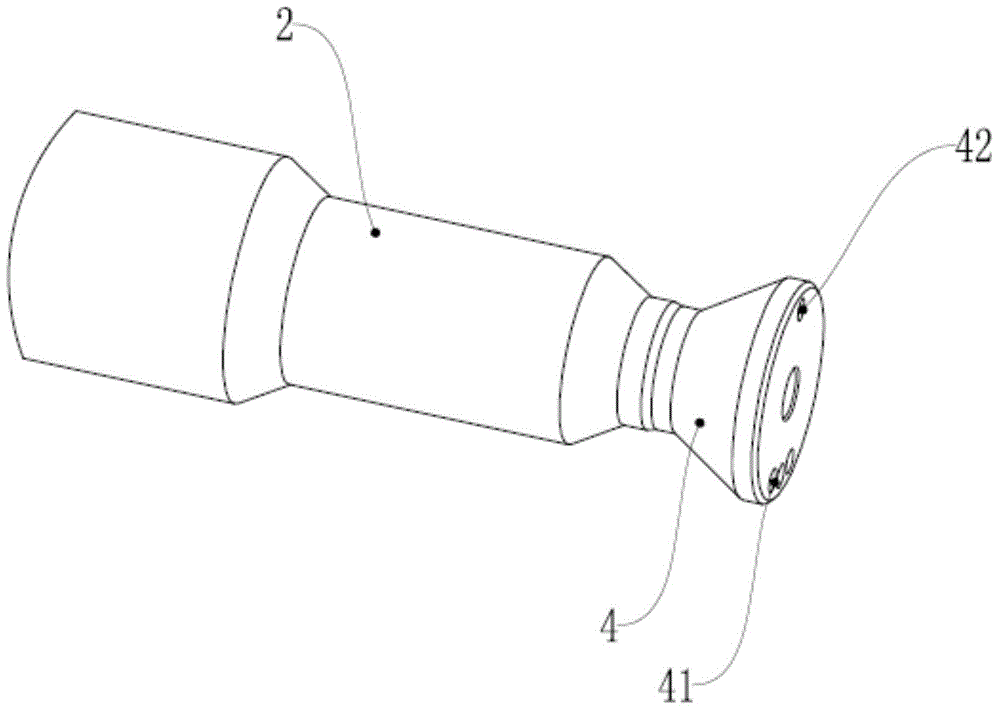

[0021] A plasma electromagnetic rotary processing device, which includes a motor 1, an electrode 3, a plasma gun head 2 and an inner core 6, the output shaft of the motor 1 is a hollow shaft 13, and the shell of the motor 1 is a shell with front and rear openings ; The rear opening of the motor 1 is equipped with a flange 9, the inner core 6 is fixed on the flange 9 and is located in the hollow shaft 13; the air pipe passes into the inner core 6; the power cord passes through the inner core 6; The core 6 is connected to the electrode 3; the plasma torch head 2 is located at the front opening of the housing 11, connected to the hollow shaft 13, and covers the electrode 3, and the nozzle position of the plasma torch head 2 One flame hole 41 and three counterweight holes 42 are provided.

[0022] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com