Hot blast furnace device for blast furnace iron making

A blast furnace ironmaking and hot blast stove technology, applied in blast furnaces, blast furnace details, blast furnace parts, etc., can solve the problems of reduced burner life, low production hot air efficiency, high burner gas density, etc., and achieve high production hot air efficiency , saving heat storage time, long burner life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

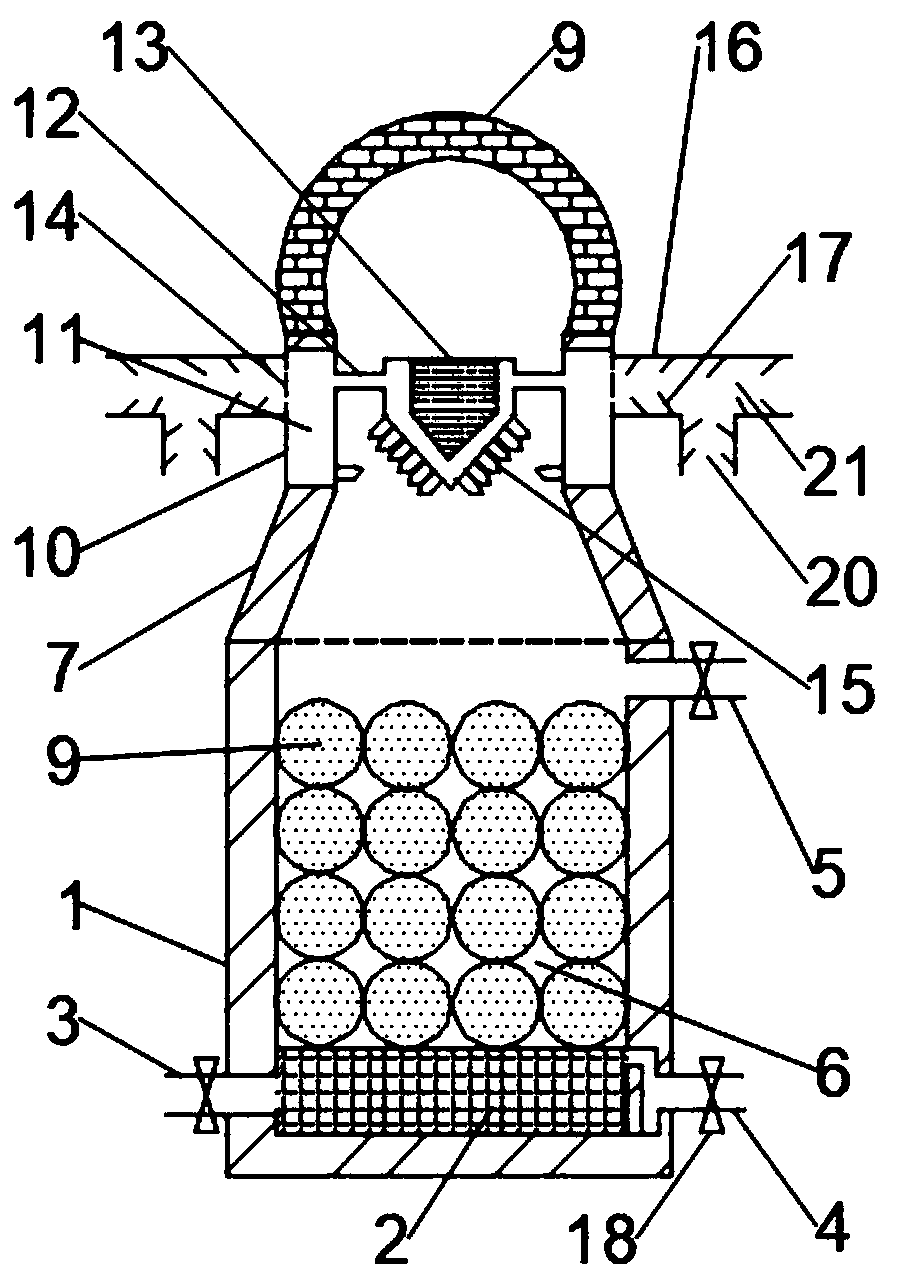

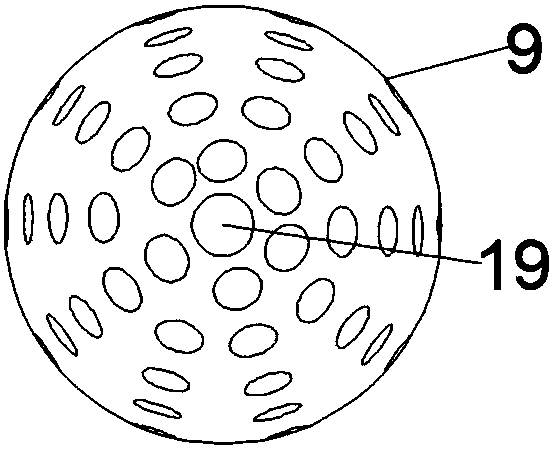

[0025] Such as figure 1 As shown, the present invention provides a hot blast stove device for blast furnace ironmaking, comprising a furnace body 1, a furnace grate 2 is installed at the bottom of the inner wall of the furnace body 1, and a cold air pipe 3 is fixedly installed at the bottom of the side wall of the furnace body 1 And the waste gas pipe 4, the top of the side wall of the furnace body 1 is fixedly equipped with a hot air pipe 5, the cold wind pipe 3 and the waste gas pipe 4 are parallel and both are symmetrical about the center of the furnace body 1, so that the cold wind pipe 3 enters the cold wind and the waste gas pipe The 4 rows of exhaust gas do not interfere with each other, and the efficiency is higher. The furnace grate 2 is located between the cold air pipe 3 and the exhaust gas pipe 4. The furnace grate 2 has two functions here. First, it makes the cold air entering from the cold air pipe 3 Evenly spread to the regenerator 6, so that the cold air is hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com