A Self-excited Oscillating Pulse Swirl Supercharger

A technology of self-excited oscillation and supercharger, which is applied in the direction of conveying bulk materials, transportation and packaging, conveyors, etc., to reduce processing difficulty and cost, and achieve good pulse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

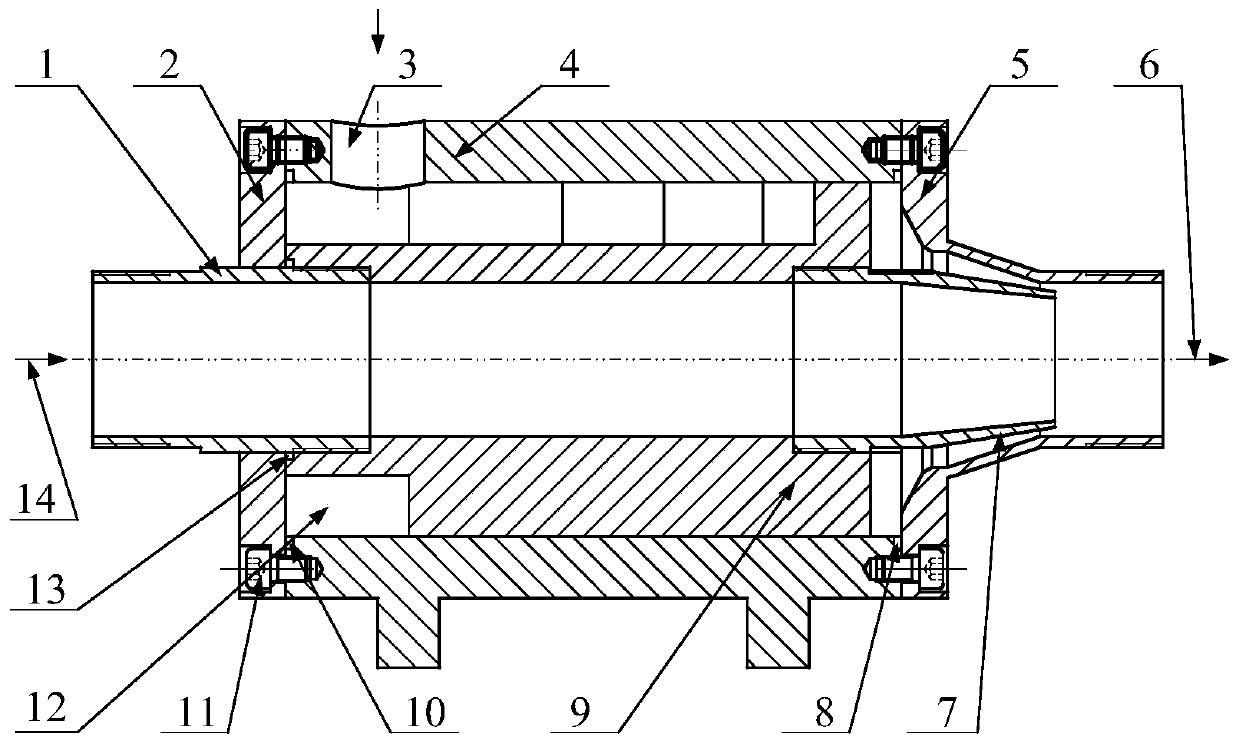

[0041] During the operation of the equipment, the air inlet 14 and the air supply port 3 use different positive pressure air sources, the powder will settle due to its own weight, accumulate in the lower part of the pipeline to form a powder mound, and continue to increase, resulting in a smaller cross-sectional area of the main air duct and an increase in wind pressure. In order to reduce energy consumption and reduce pipeline wear, long-distance pneumatic transportation of materials often uses low-pressure air volume. When the wind pressure is not enough to blow through the piles of materials accumulated in the pipeline, pipeline blockage will occur.

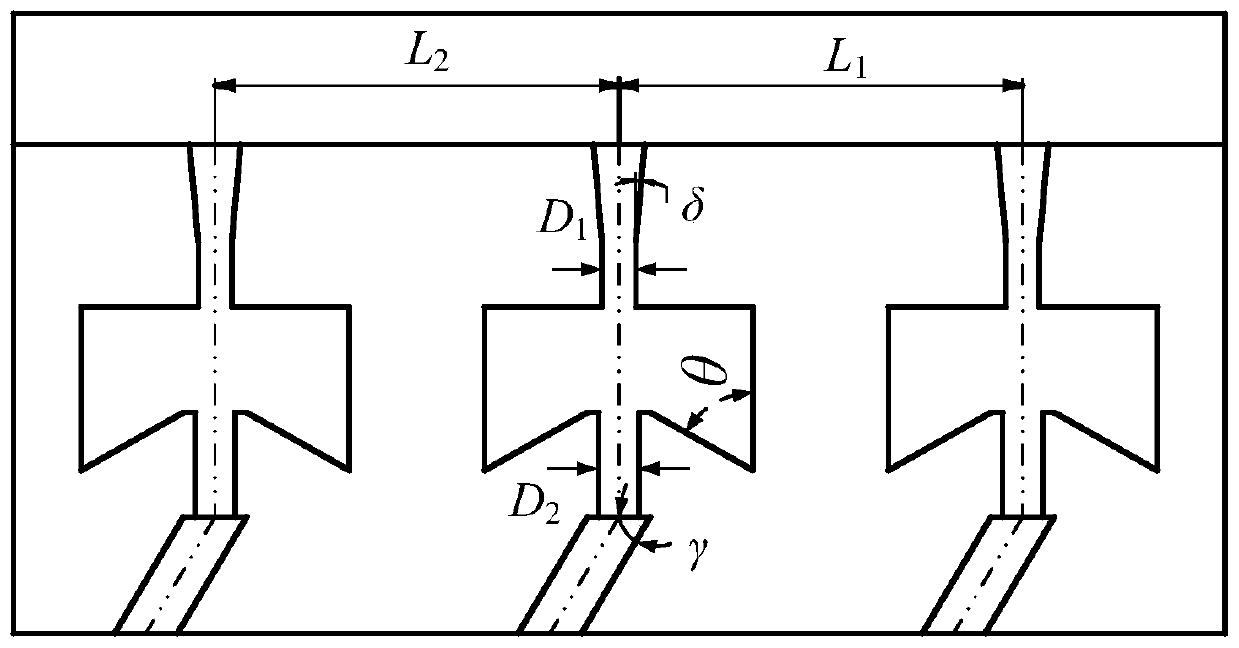

[0042] When the air is replenished from the air supply port 3, the strong air flow enters the main pipeline through the central axis 9 of the pulse swirl, and flows out from the blocked rear end of the pipeline, forming a turbulent flow, disturbing and dividing the material pile and moving forward until the clogged material ma...

Embodiment 2

[0044] The outlet gas regulating pipe 7 of the pulse swirl supercharger adopts the end reducer structure. When the gas velocity is low, the material will be accumulated inside the supercharger. At this time, the pulse swirl supercharger acts as the first embodiment; when the gas velocity When the speed is sufficient to prevent the particles from clogging in the supercharger, that is, when the particles can pass through the cyclone supercharger smoothly, the tapered inclination angle design of the outlet regulating pipe 7 can make the particles be disturbed when passing through the outlet regulating pipe, so that The particles move along the entire pipeline to the outlet instead of sliding or rolling with the bottom of the pipeline, and when the diameter of the pipeline decreases, the velocity of the flow field will increase, and the material can be accelerated within a certain distance. The full pipe transportation of materials can not only prevent pipeline blockage, but also r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com