Patents

Literature

30results about How to "Guaranteed collinear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

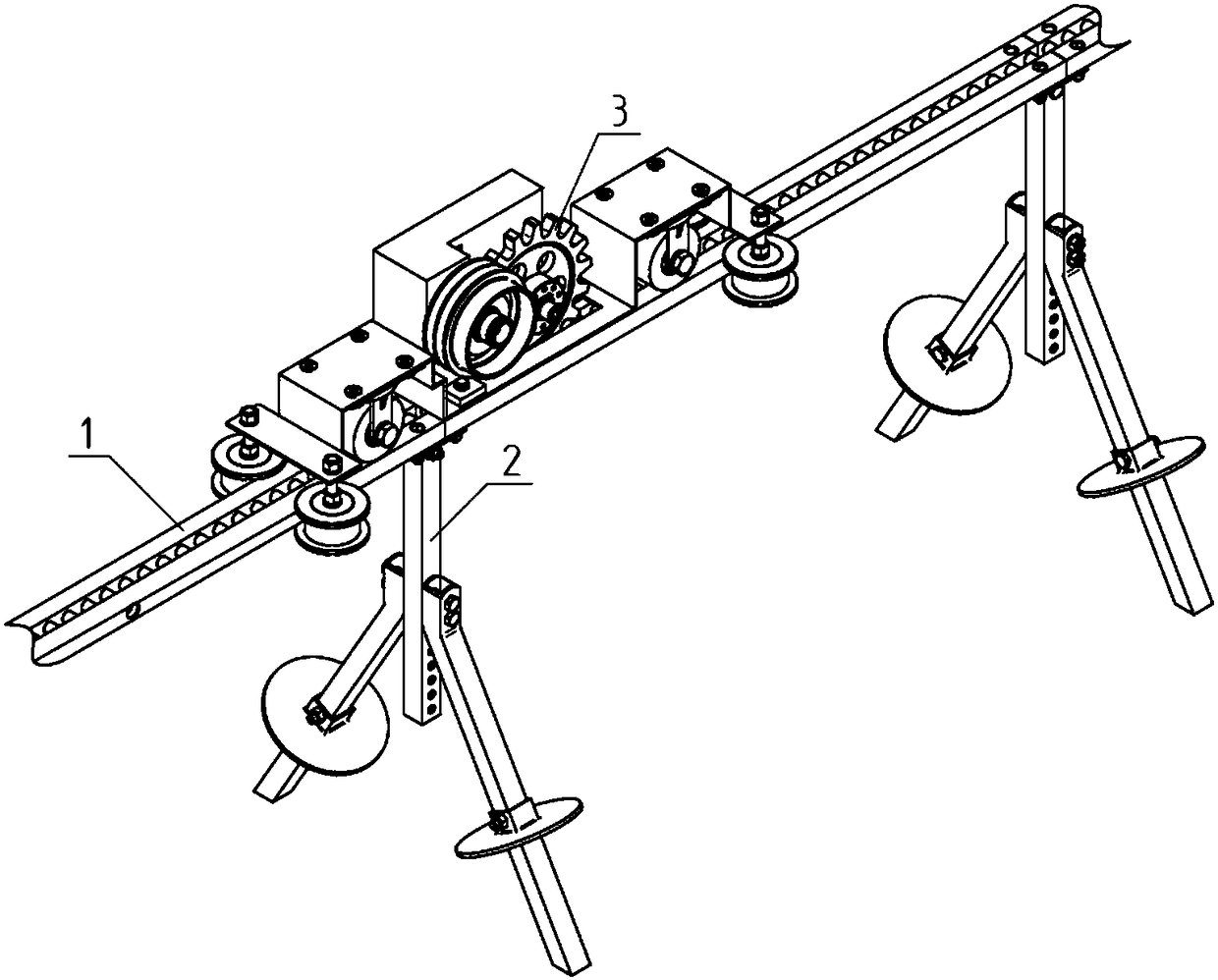

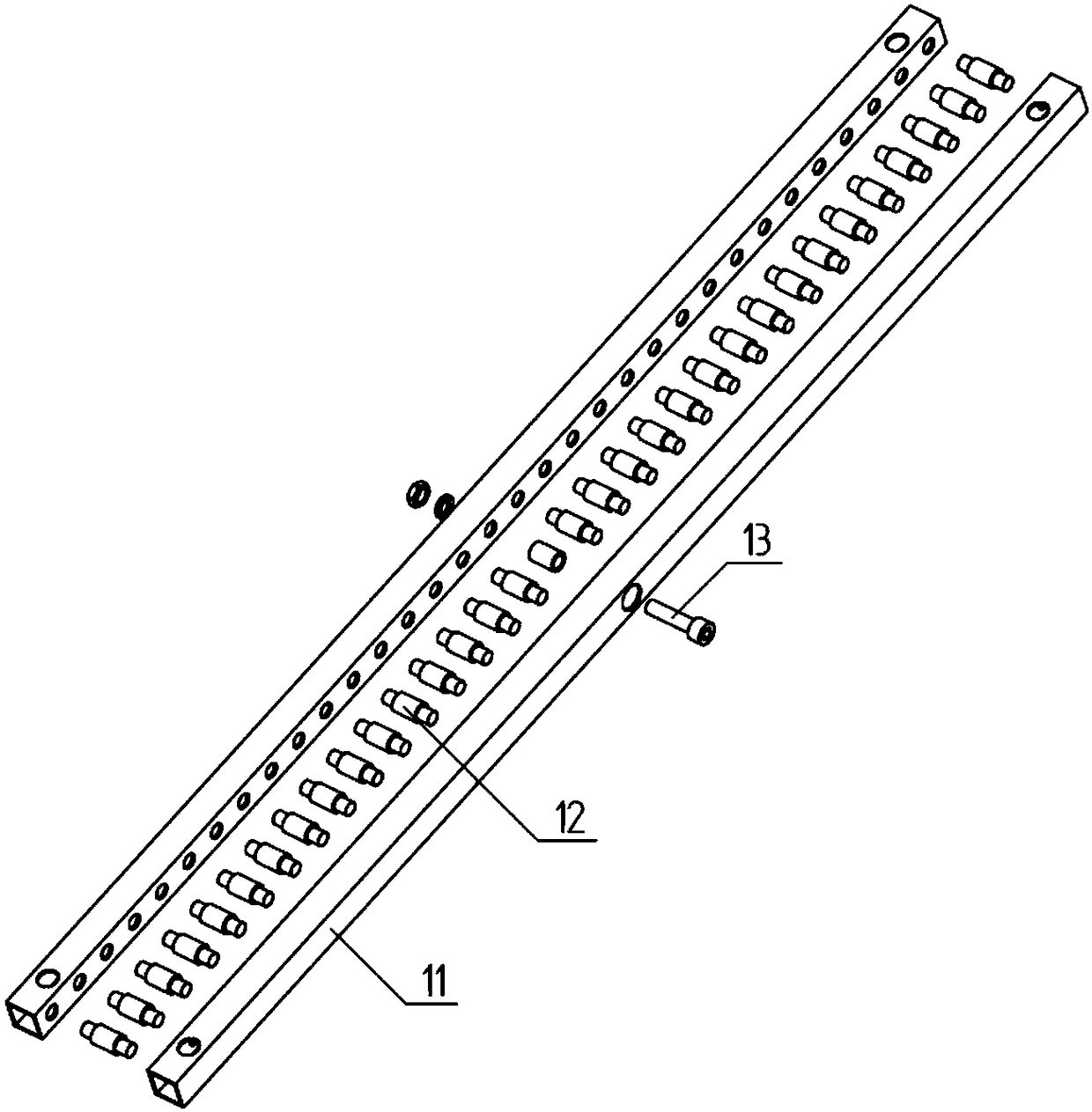

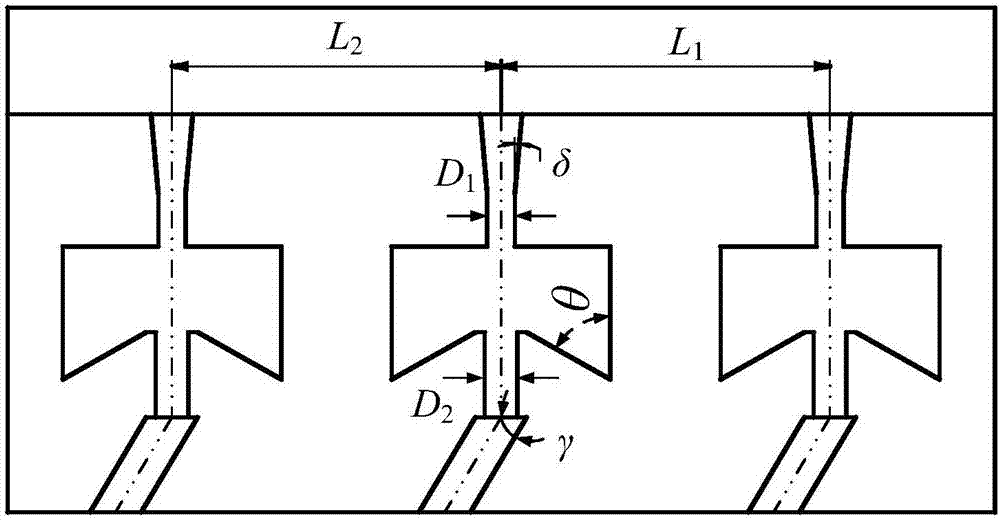

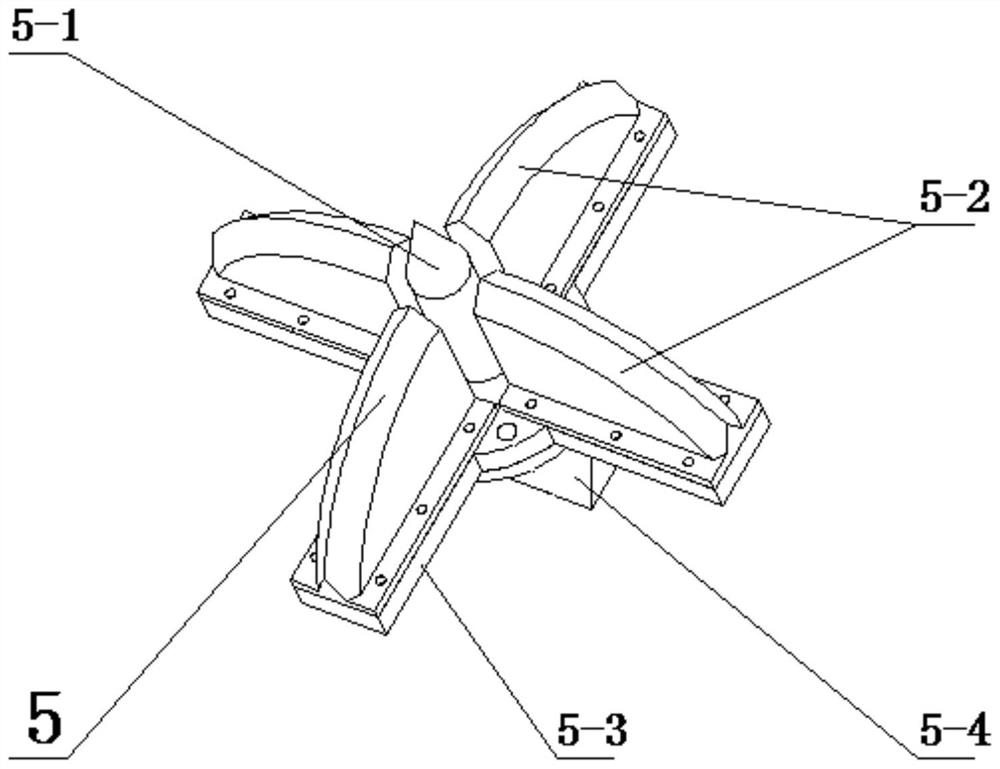

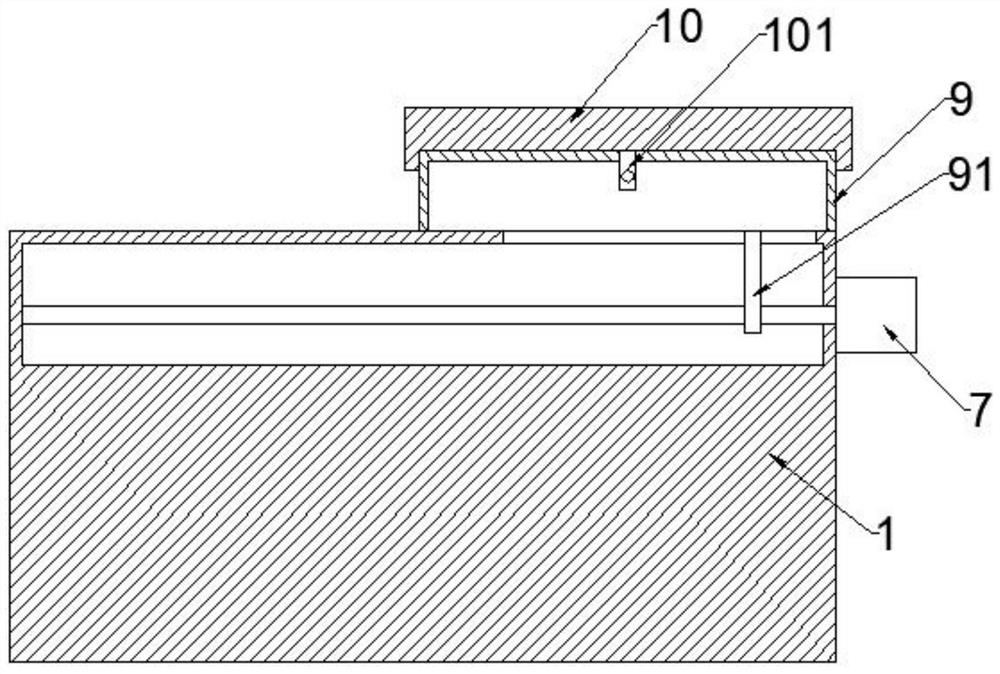

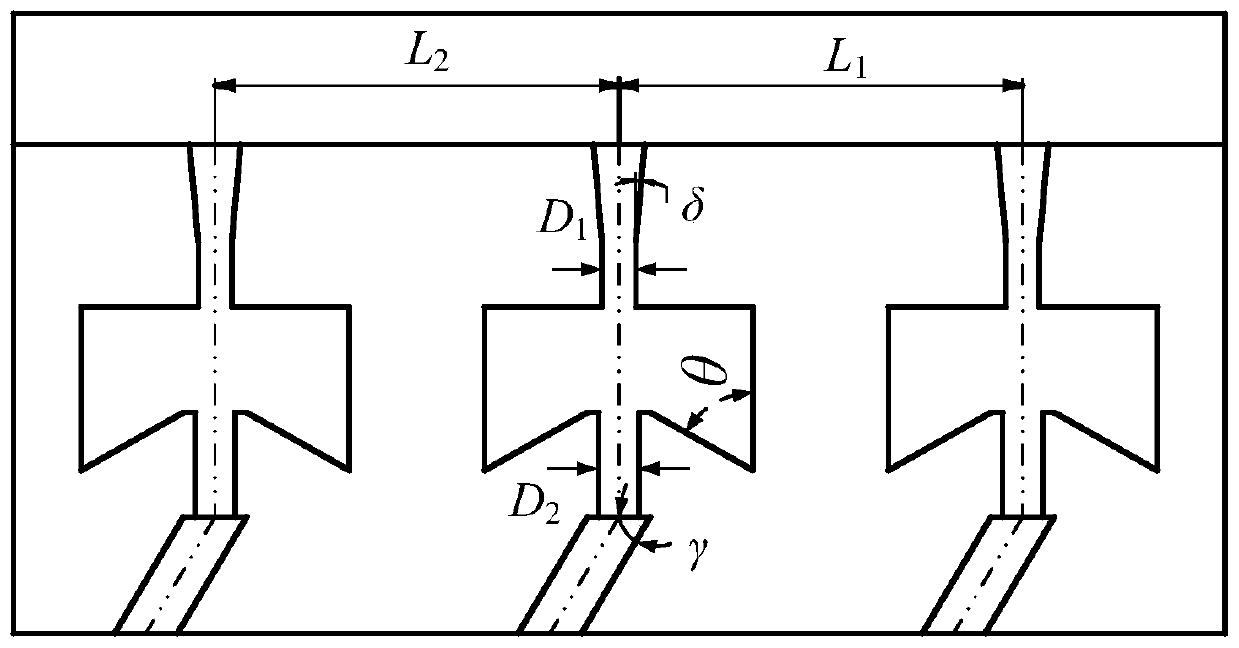

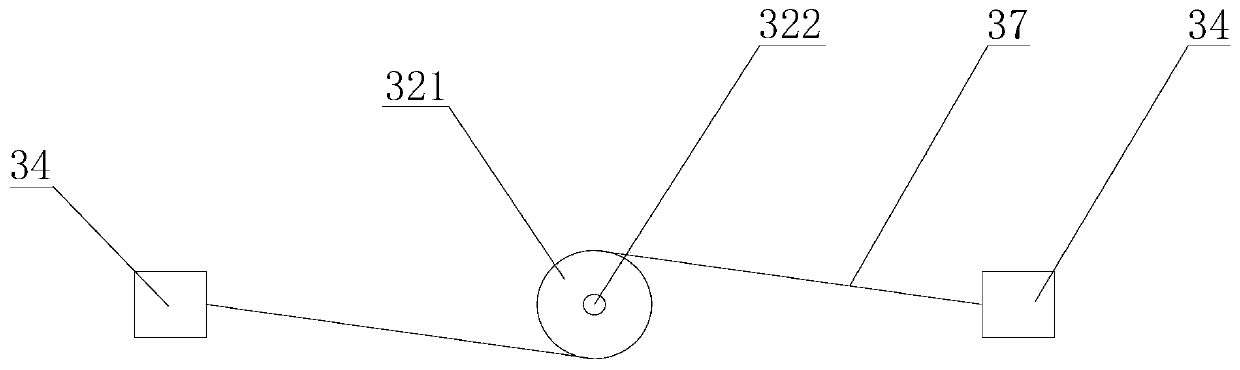

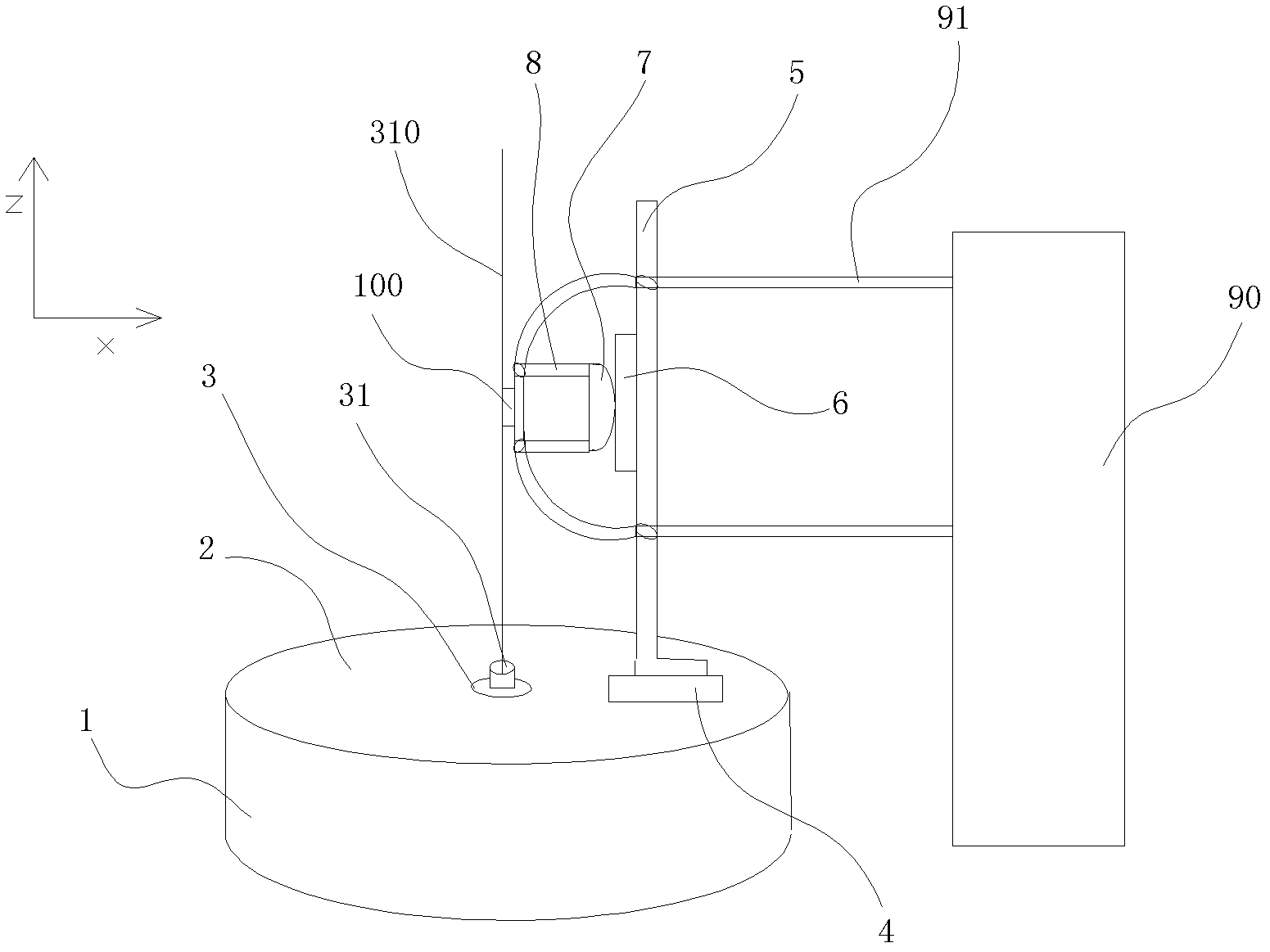

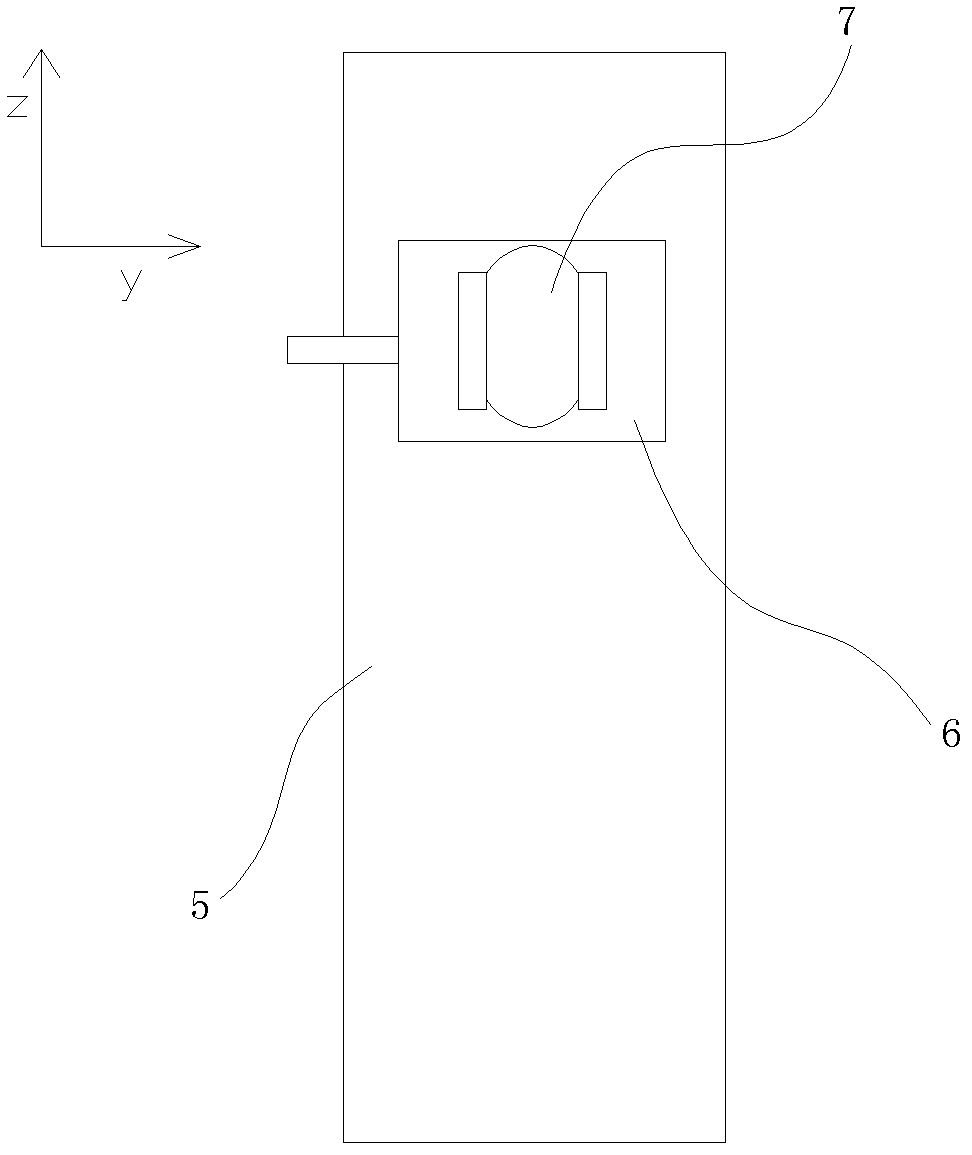

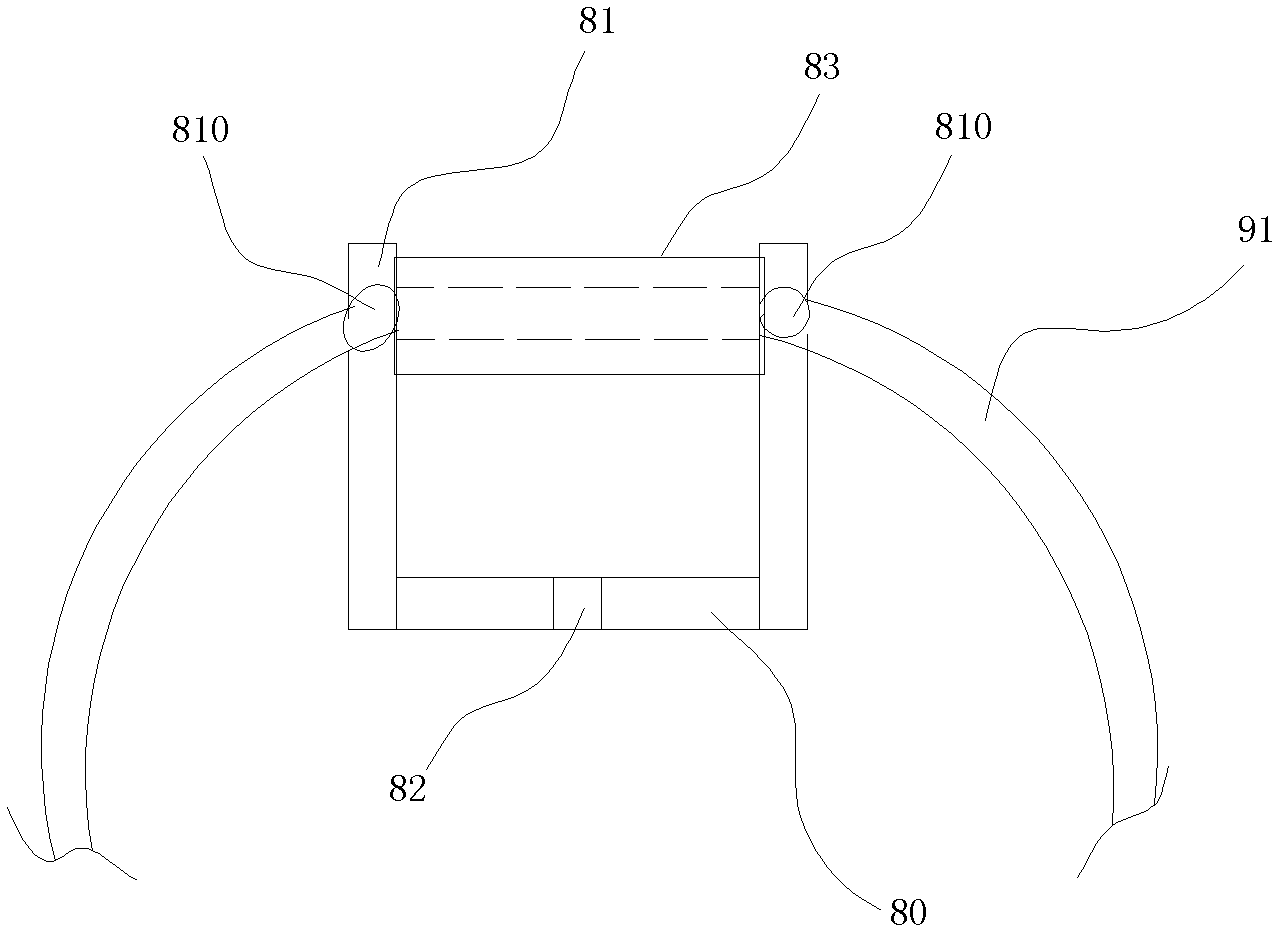

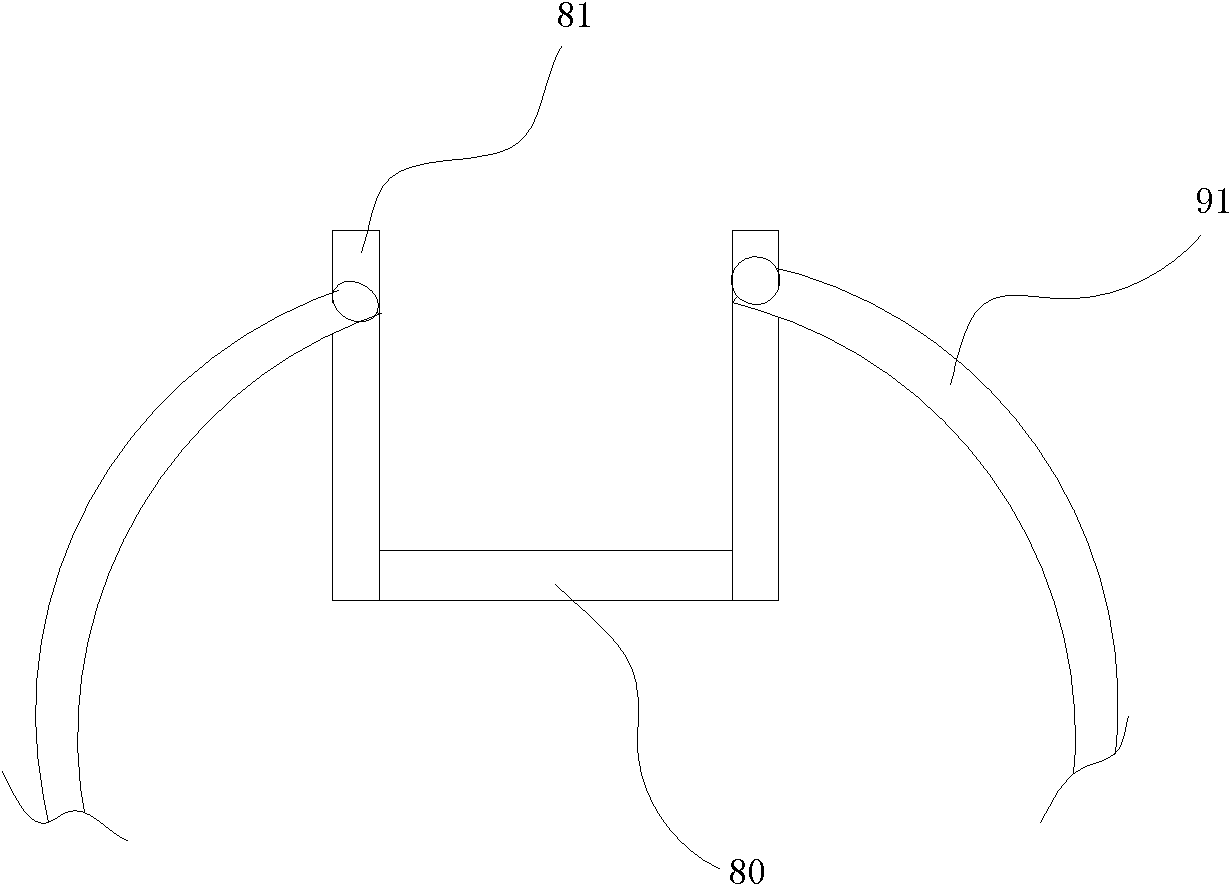

Pin ladder type forestry mountain monorail vehicle track

The invention relates to the technical field of monorail transit vehicles and discloses a pin ladder type forestry mountain monorail vehicle track which comprises a track body, supporting mechanisms and a gear train, wherein the supporting mechanisms are used for supporting the track body so that the whole track can be flexibly adapted to flat lands or slope lands; the gear train is capable of rolling on the track body and carrying the load of a monorail vehicle and has a guiding function; the track body comprises track beams and pin shafts; the track beams are made of hollow square steel; thetwo track beams are oppositely arranged and connected by the pin shafts to form a pin ladder shape; the gear train comprises a driving gear, guiding wheels and load bearing wheels; and the driving gear is in meshing transmission with the pin shafts. The pin ladder type forestry mountain monorail track is low in cost, good in stability, flexible in installation and simple in structure.

Owner:BEIJING FORESTRY UNIVERSITY

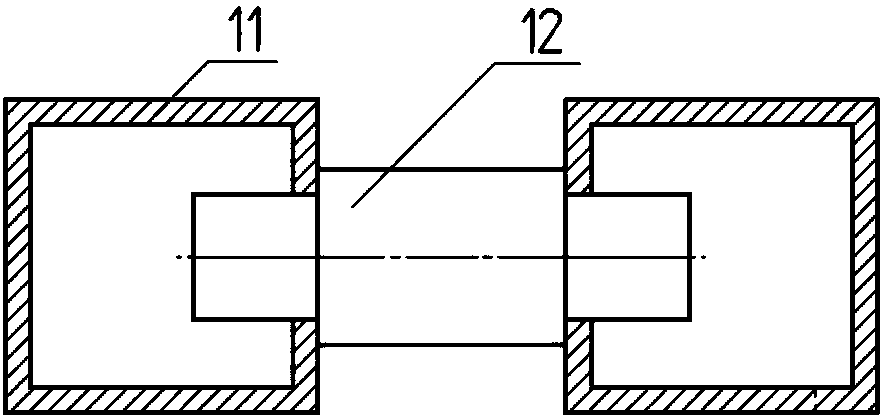

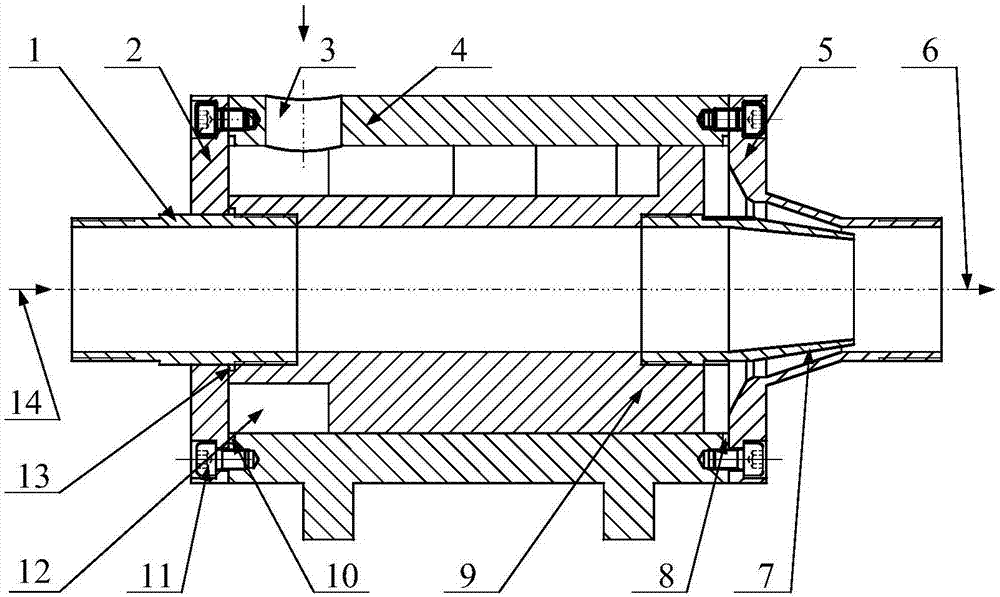

Self-oscillation type pulse cyclone supercharger

InactiveCN107082283AGuaranteed to be continuously adjustableGuaranteed collinearBulk conveyorsCycloneSelf-oscillation

The invention provides a self-oscillation type pulse cyclone supercharger. The self-oscillation type pulse cyclone supercharger comprises a shell, an air inlet adjusting pipe, a left end cover, a pulse cyclone blade, an air outlet adjusting pipe and a right end cover; a main air inlet and a main air outlet are formed in the left end and the right end of the shell correspondingly; the left end cover and the right end cover of the shell are fixed through an M8 screw; the pulse cyclone blade is arranged inside the shell; the air inlet adjusting pipe is installed at the left end of the pulse cyclone blade; the air outlet adjusting pipe is installed at the right end of the pulse cyclone blade; two supporting leg bases are welded to the shell; the pulse cyclone blade comprises a center sleeve pipe and a cyclone blade arranged at the concave portion of the center sleeve pipe; particles and gas in the center sleeve pipe flow in the axial direction; a pulse cyclone air flow is formed between the shell and the pulse cyclone blade; and an auxiliary supplementing air inlet is formed in the shell and is in G1 pipe threaded connection. The self-oscillation type pulse cyclone supercharger is wide in application range, can reduce the minimum conveying speed of the particles, relieve the pipe abrasion, reduce particle crushing and avoid pipe blockage, and is suitable for pneumatic long-distance conveying of material particles.

Owner:CHINA UNIV OF MINING & TECH

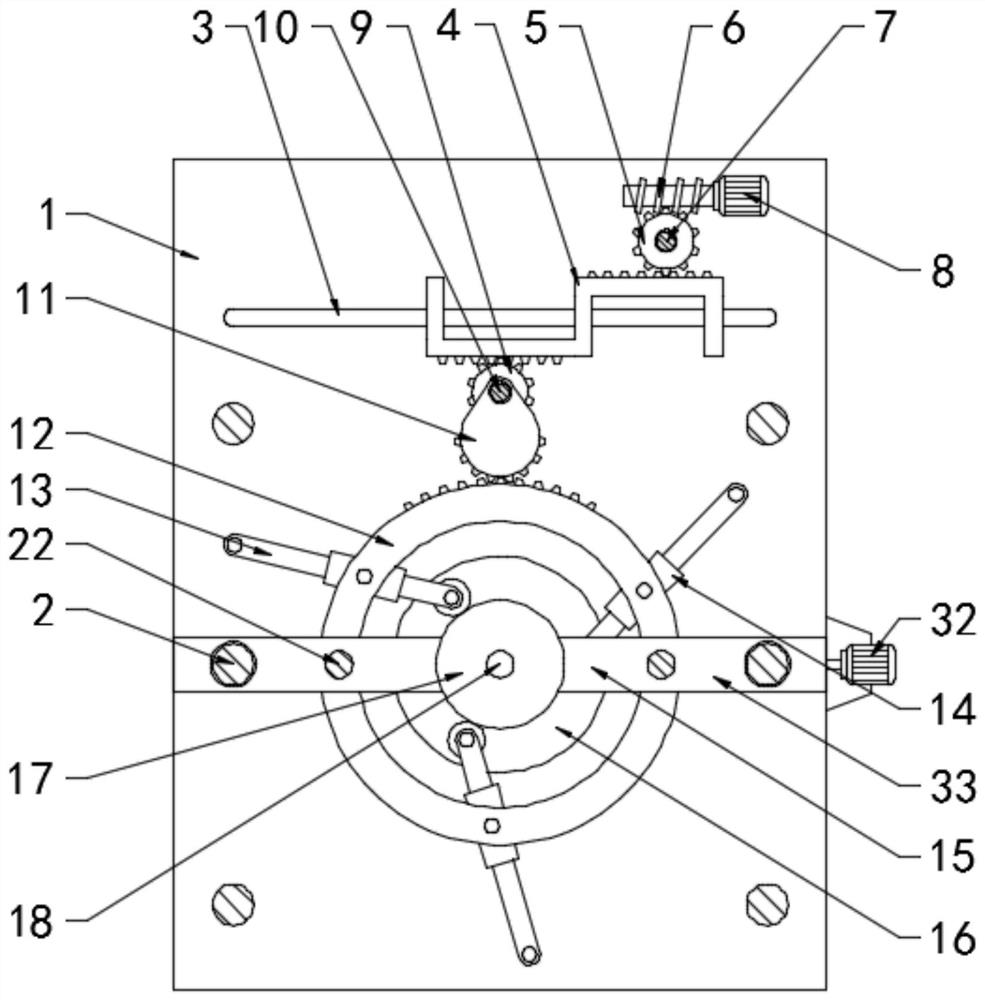

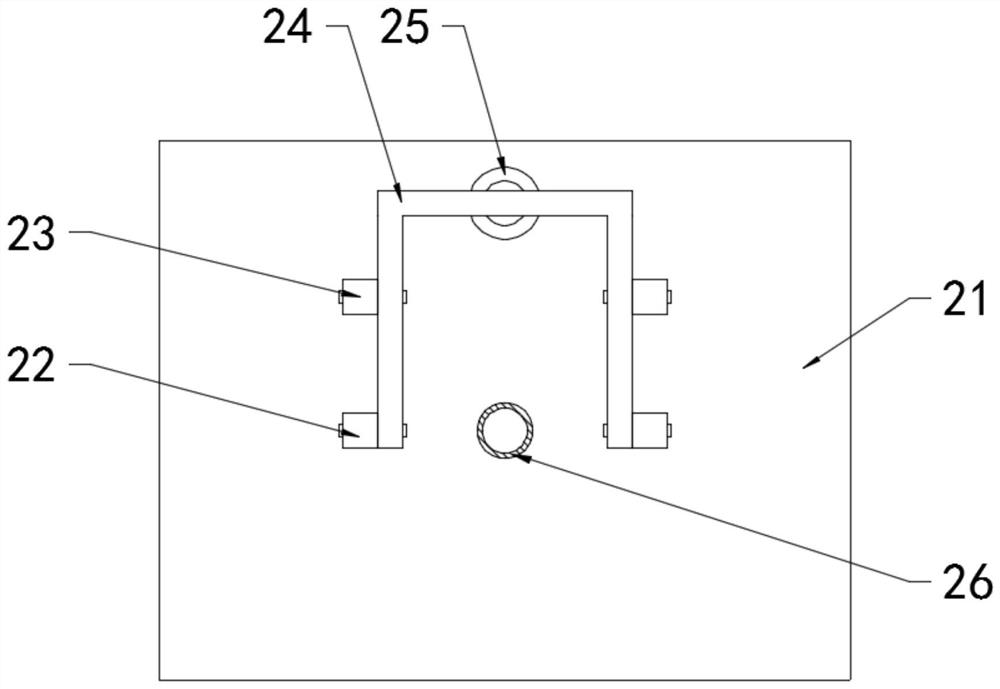

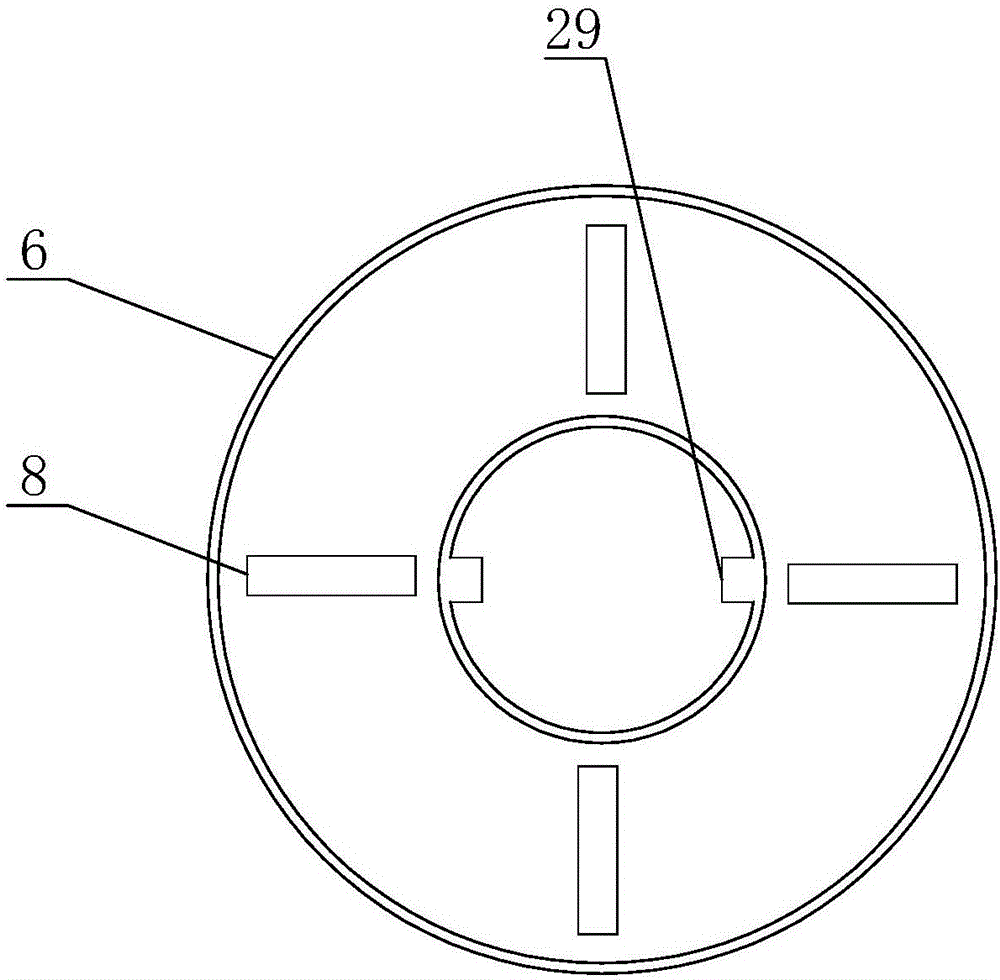

Rapid clamping and casting mechanism applied to field of casting

InactiveCN112453371AForward and reverseRealize the purpose of automatic centeringFoundry mouldsFoundry coresEngineeringMechanical engineering

The invention discloses a rapid clamping and casting mechanism applied to the field of casting. The rapid clamping and casting mechanism comprises a base, a mold with a casting port at the top is fixedly mounted on the base, a sleeve for placing the mold is rotatably mounted at the top of the base, a plurality of through grooves are formed in the outer side of the sleeve, sliding sleeves are rotatably mounted in the through grooves, first connecting rods slidably connected with the sliding sleeves are rotatably mounted at the top of the base, and the free ends of the multiple first connectingrods are rotatably connected with rollers tangent to the surface of the mold. According to the rapid clamping and casting mechanism, when the sleeve rotates clockwise, the first connecting rods are driven to rotate outwards relative to the mold, the mold is loosened and taken out conveniently, when the sleeve rotates anticlockwise, the first connecting rods are driven to rotate inwards relative tothe mold, the mold is clamped, the mold is fixed conveniently, meanwhile, automatic centering of the mold can be achieved, it is guaranteed that the central axis of the mold and the central axis of the sleeve are collinear, therefore, accurate communication between a casting funnel and the casting port is guaranteed, and molten iron splashing or overflowing during casting is avoided.

Owner:安徽绿能技术研究院有限公司

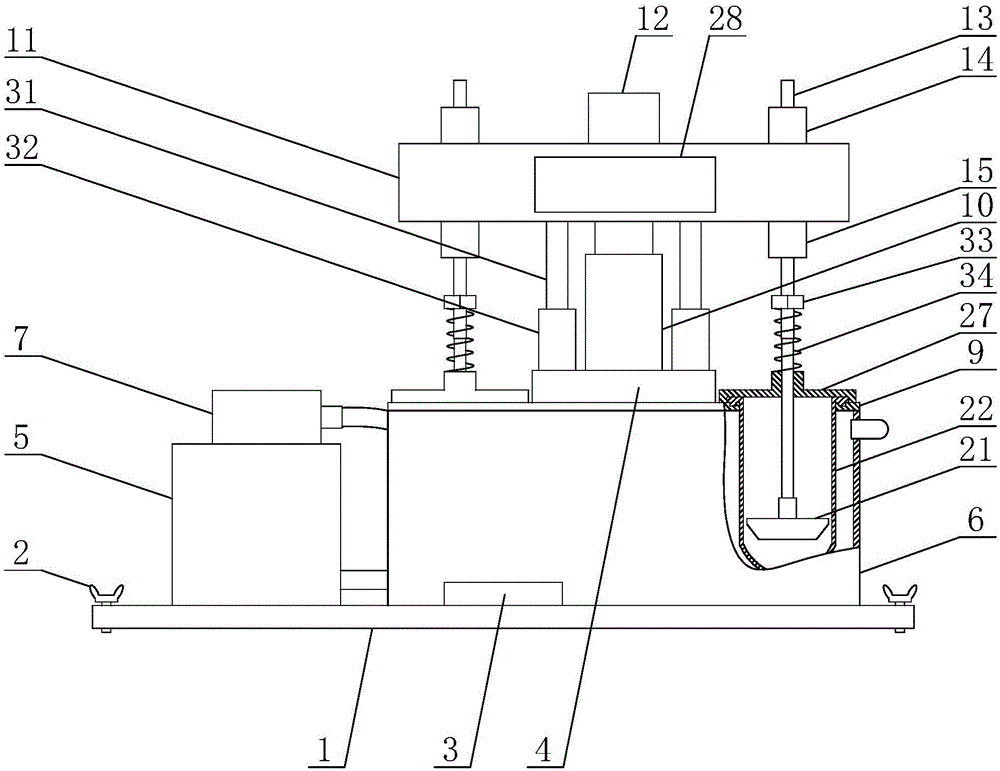

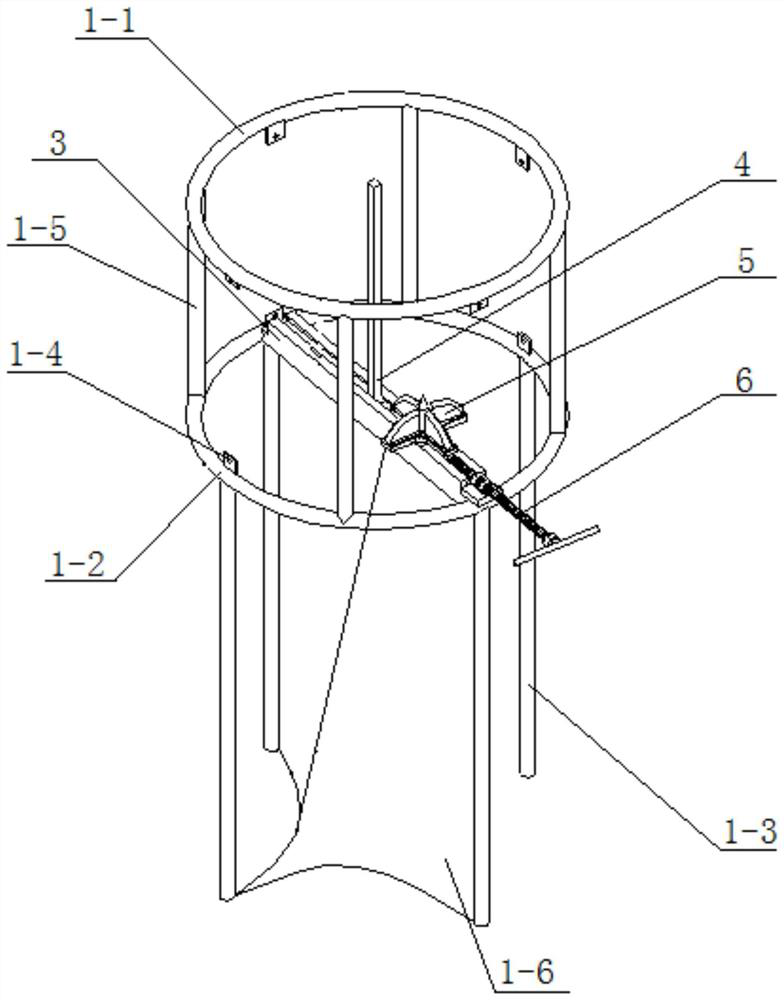

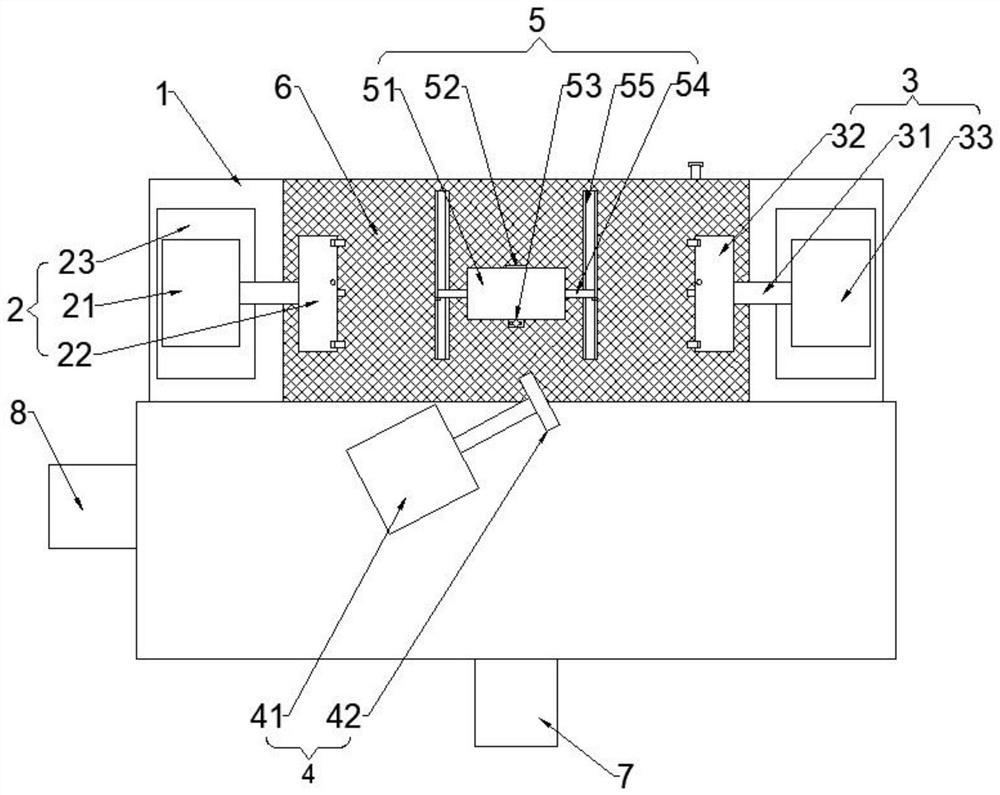

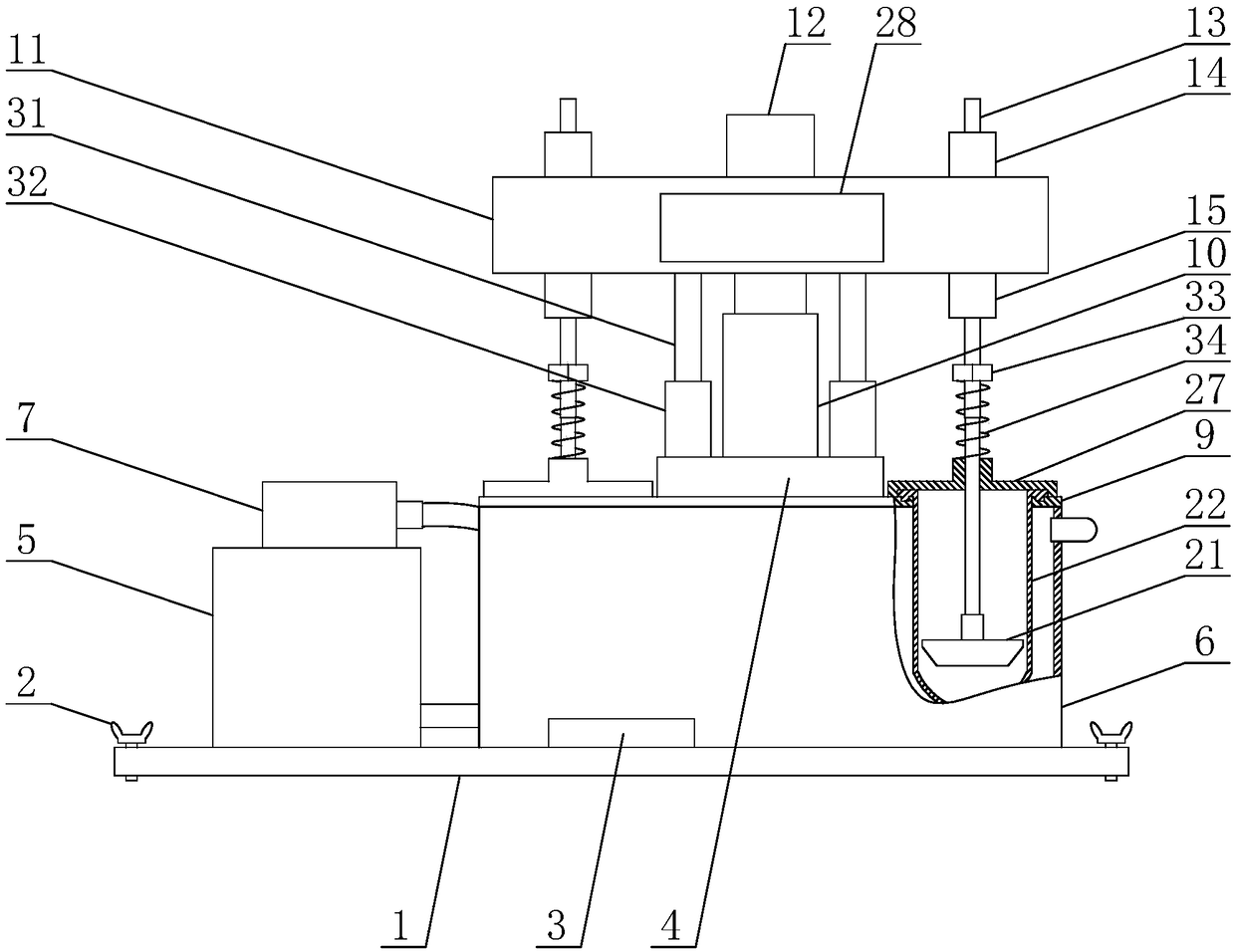

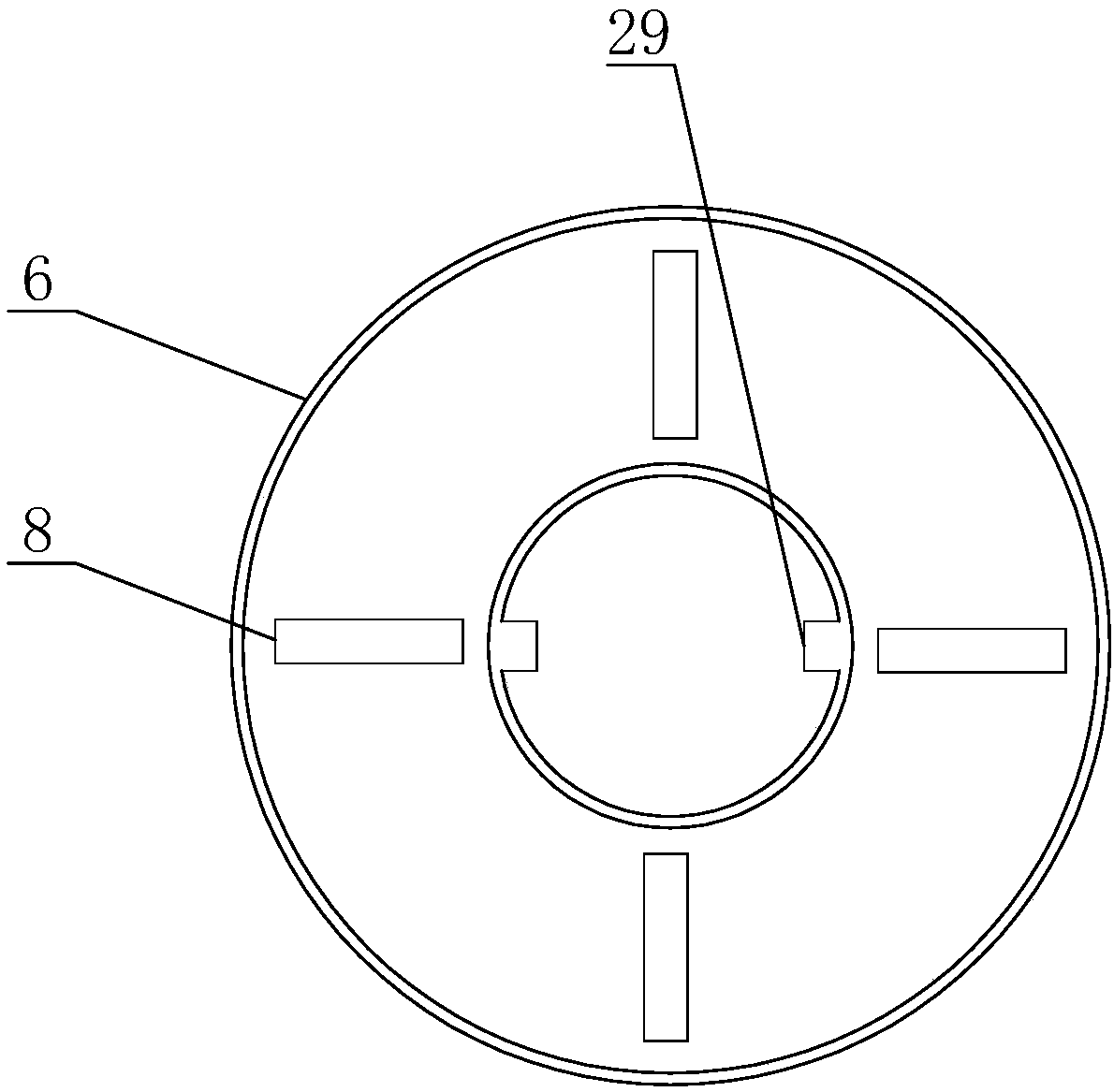

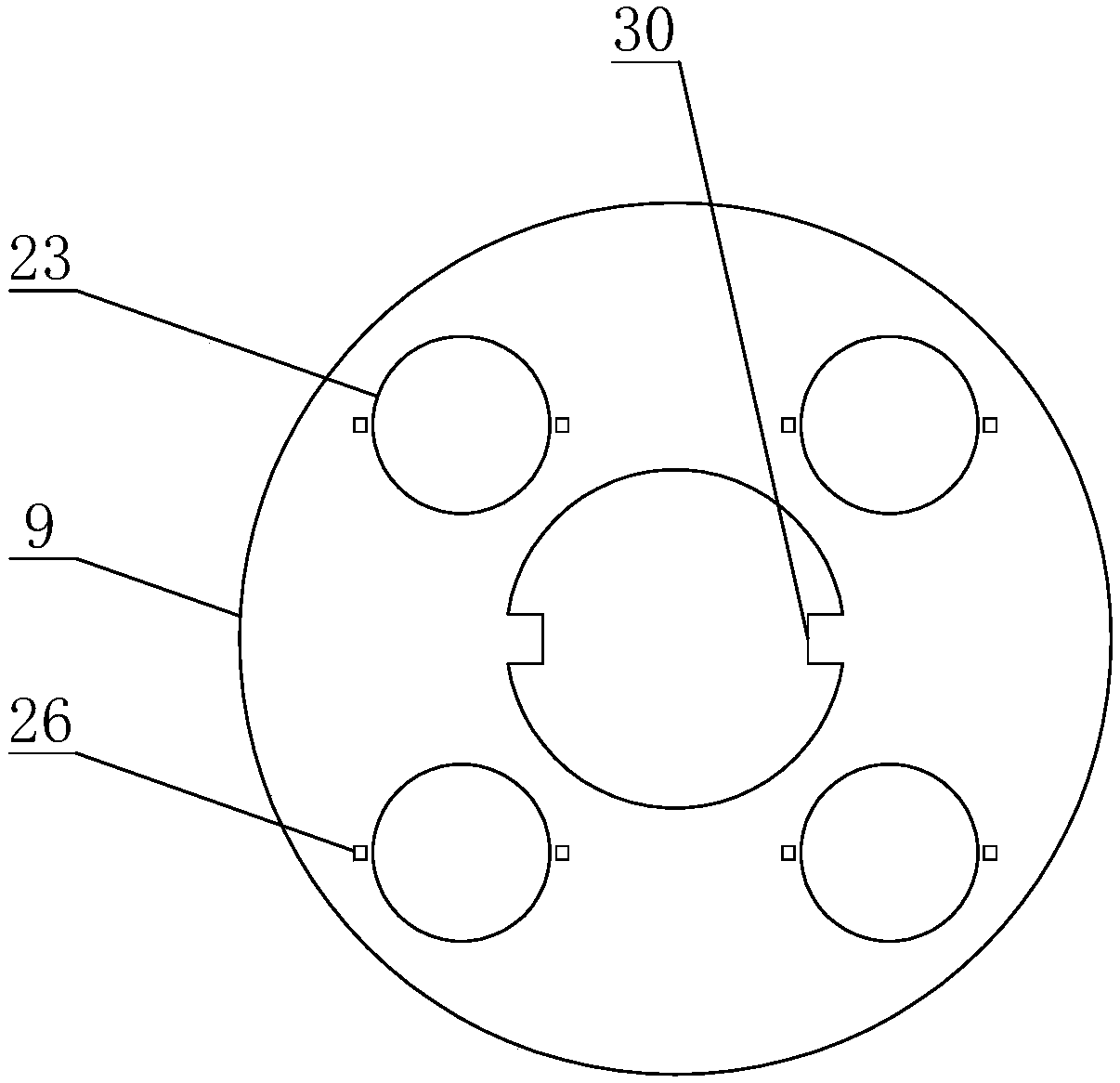

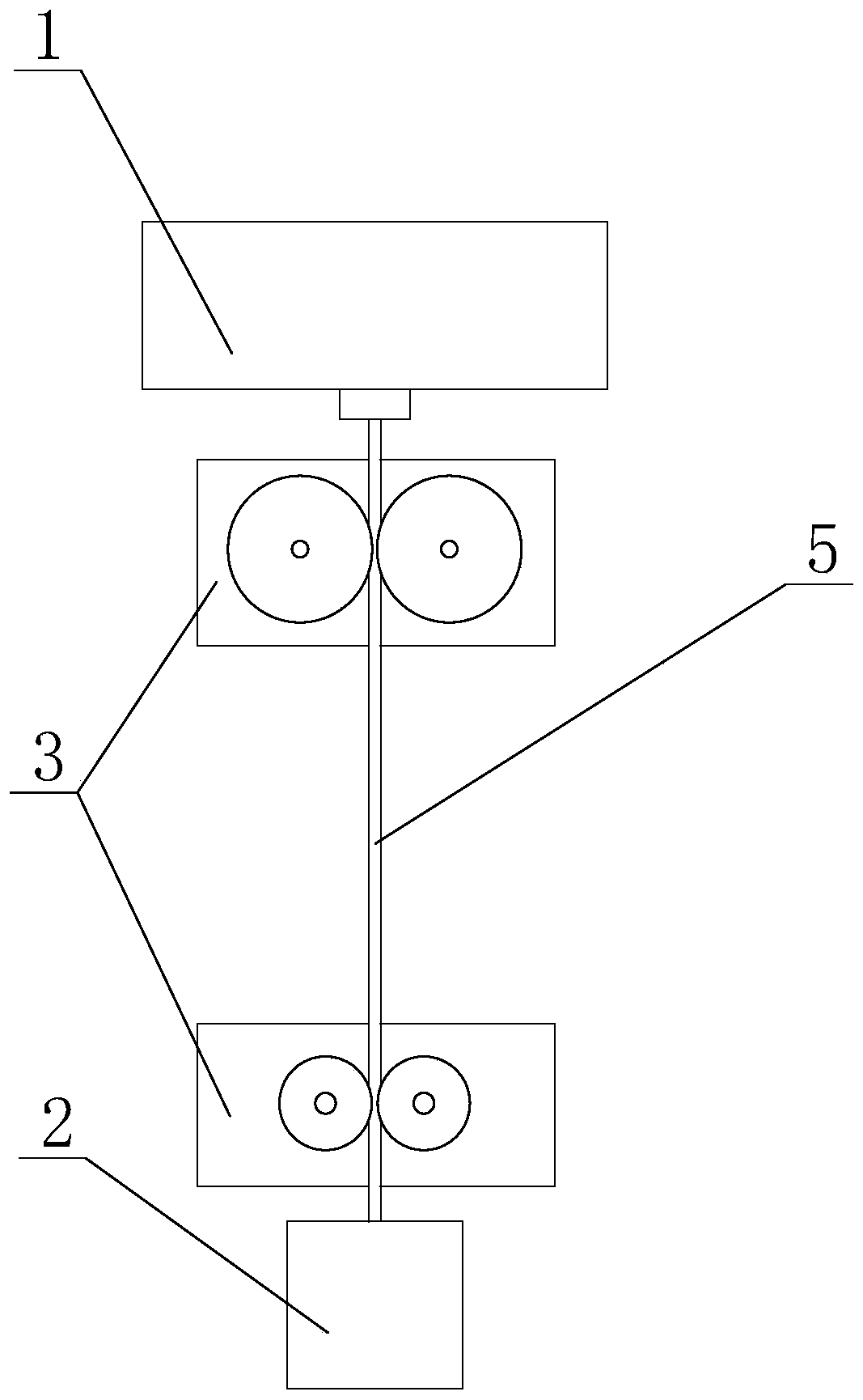

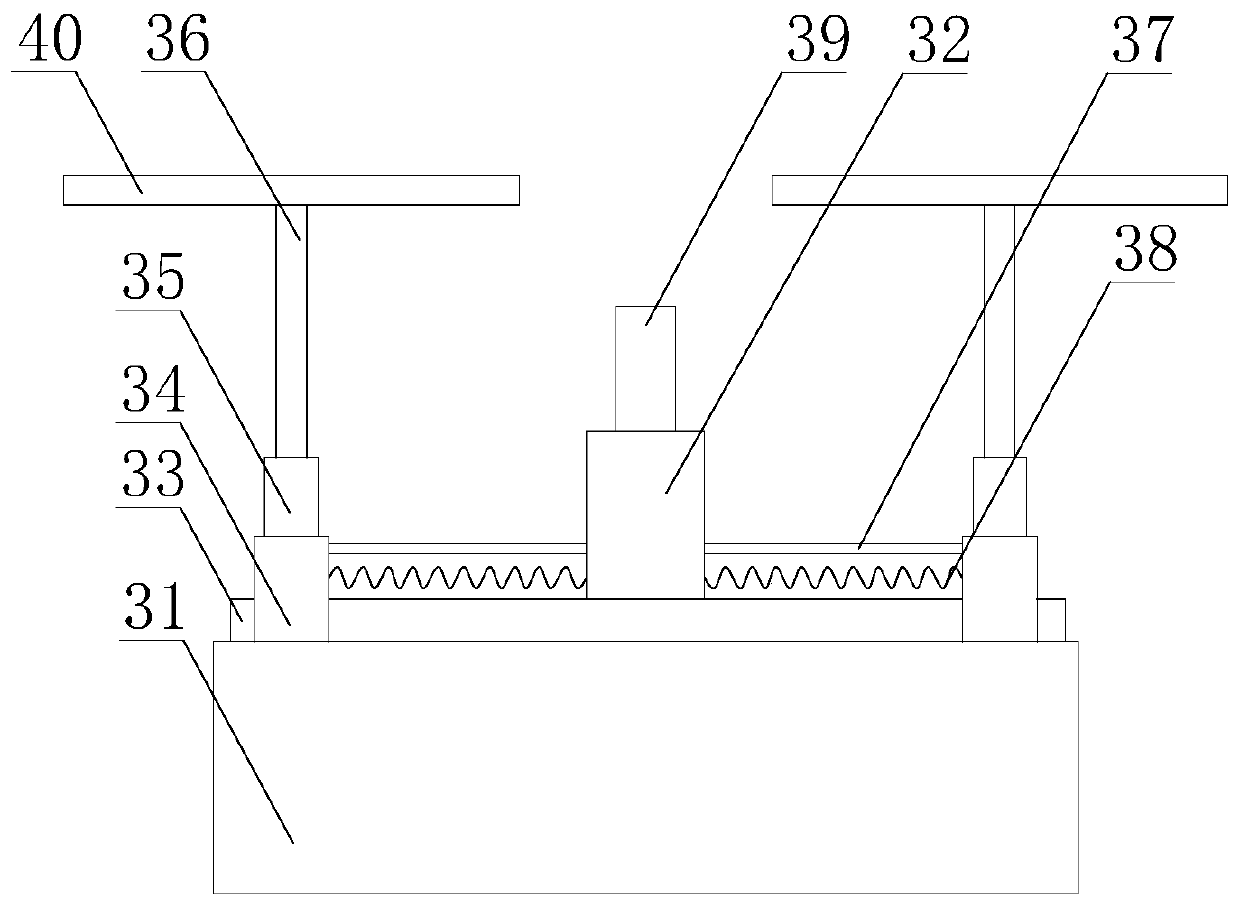

Test instrument for dissolution rate of drugs

ActiveCN106442904AGuaranteed credibilityIncrease support distanceTesting medicinal preparationsWater bathsInterference factor

The invention discloses a test instrument for dissolution rate of drugs and mainly relates to the technical field of drug inspection. The test instrument comprises a base, wherein four adjusting bolts are arranged at the edge of the base; a reference block is arranged on the base; a level bubble is arranged on the reference block; a cylindrical lug boss and a heating box are arranged at the top of the base; an annular water bath box is arranged on the cylindrical lug boss in a sleeving manner; an annular cover is arranged at the top of the annular water bath box; a lifting mechanism is arranged on the cylindrical lug boss; a cylindrical shell is arranged at the top of the lifting mechanism; a driving motor is arranged at the top of the cylindrical shell; a plurality of rotating shafts are annularly arrayed on the cylindrical shell; stirring paddles are arranged at the bottom of the rotating shafts; a dissolving cup is arranged in the annular water bath box. The test instrument has the beneficial effects of reducing the interference factor of the dissolution rate test, guaranteeing the reliability of the test result, shortening the time for correcting the test instrument for dissolution rate and improving the working efficiency.

Owner:上海安德盛实业有限公司

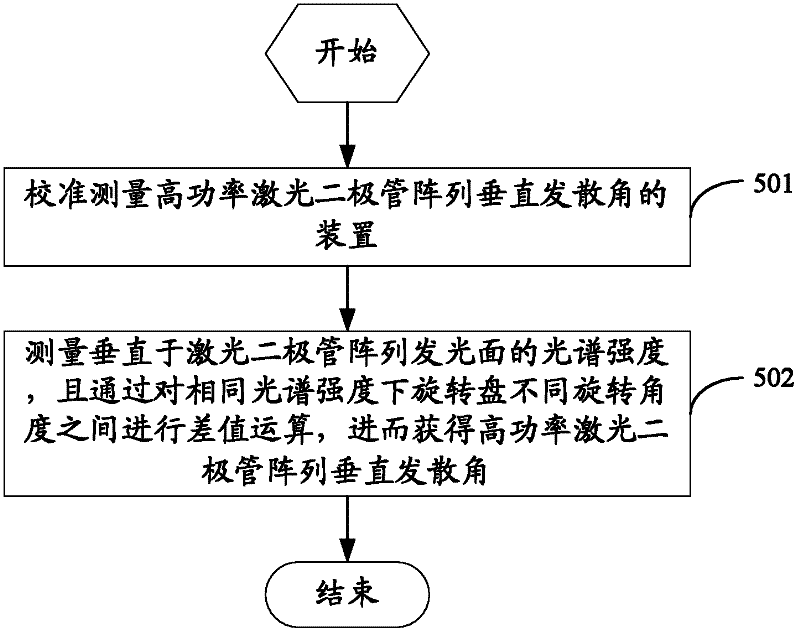

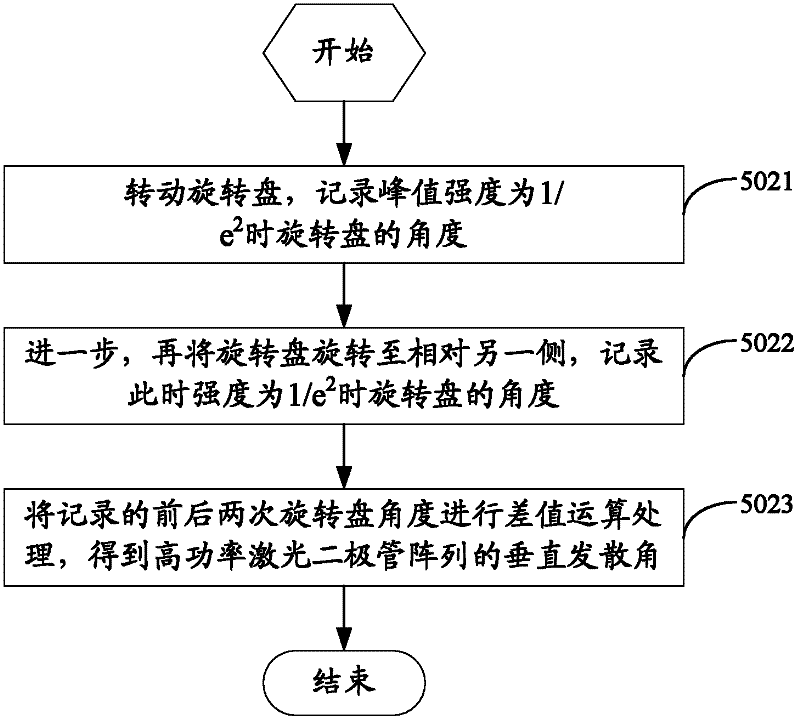

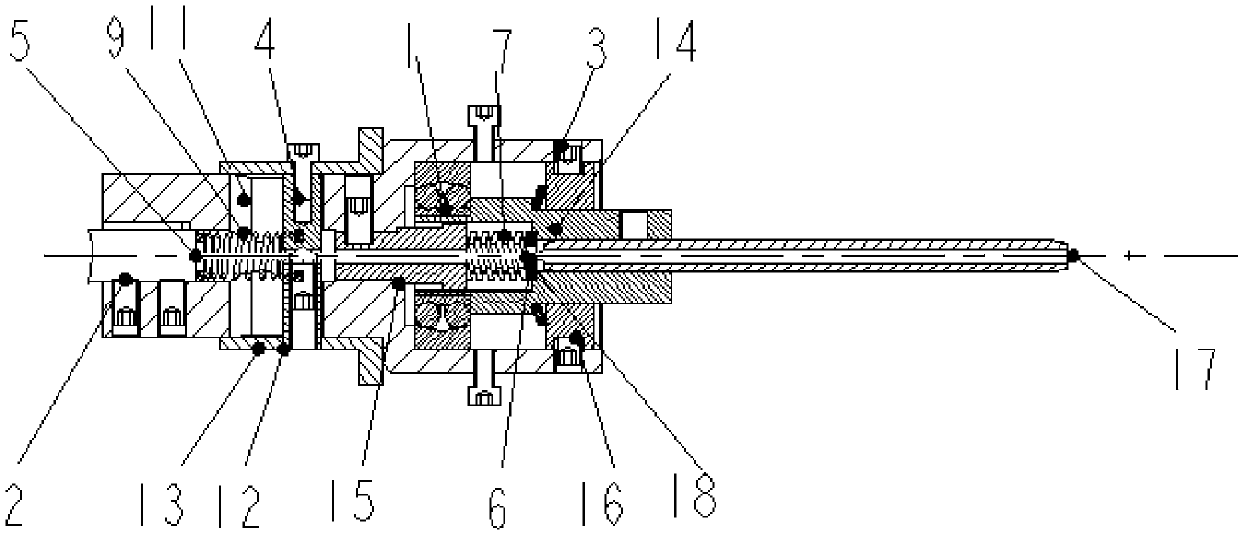

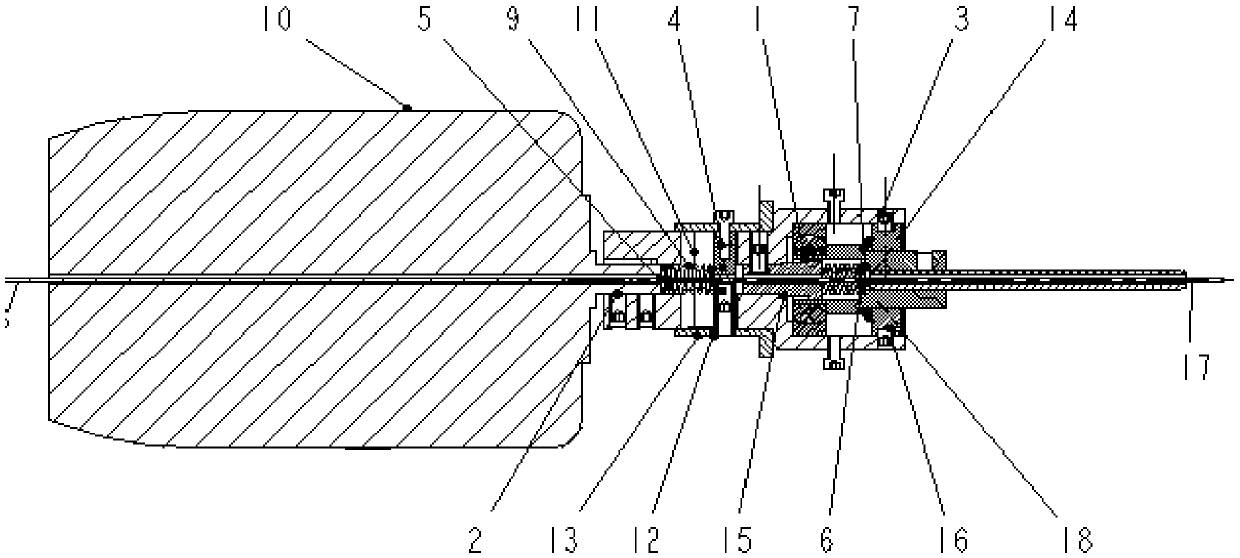

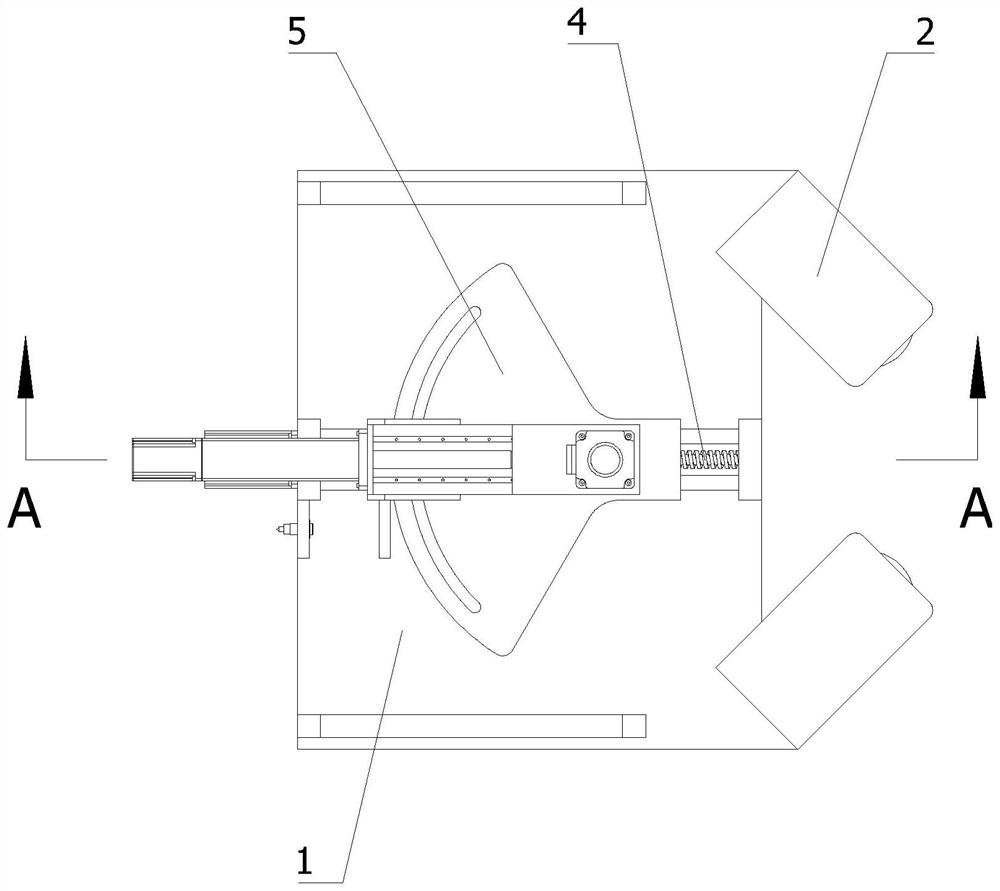

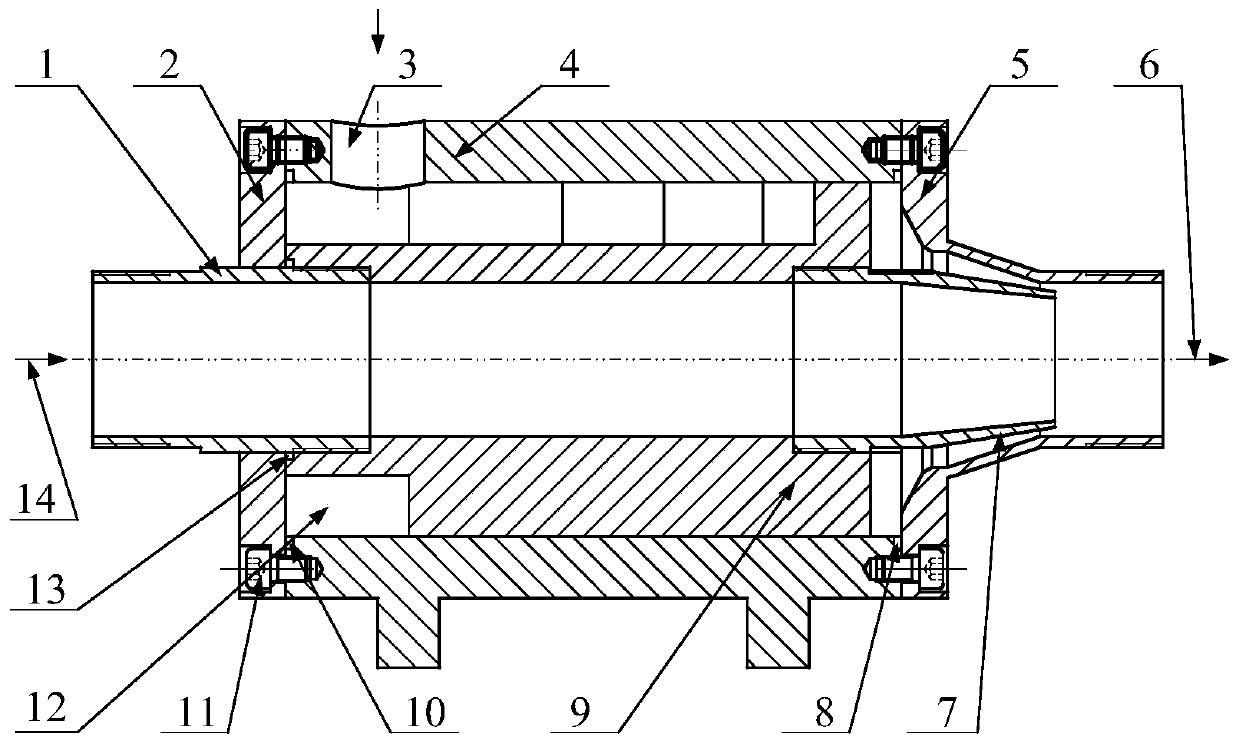

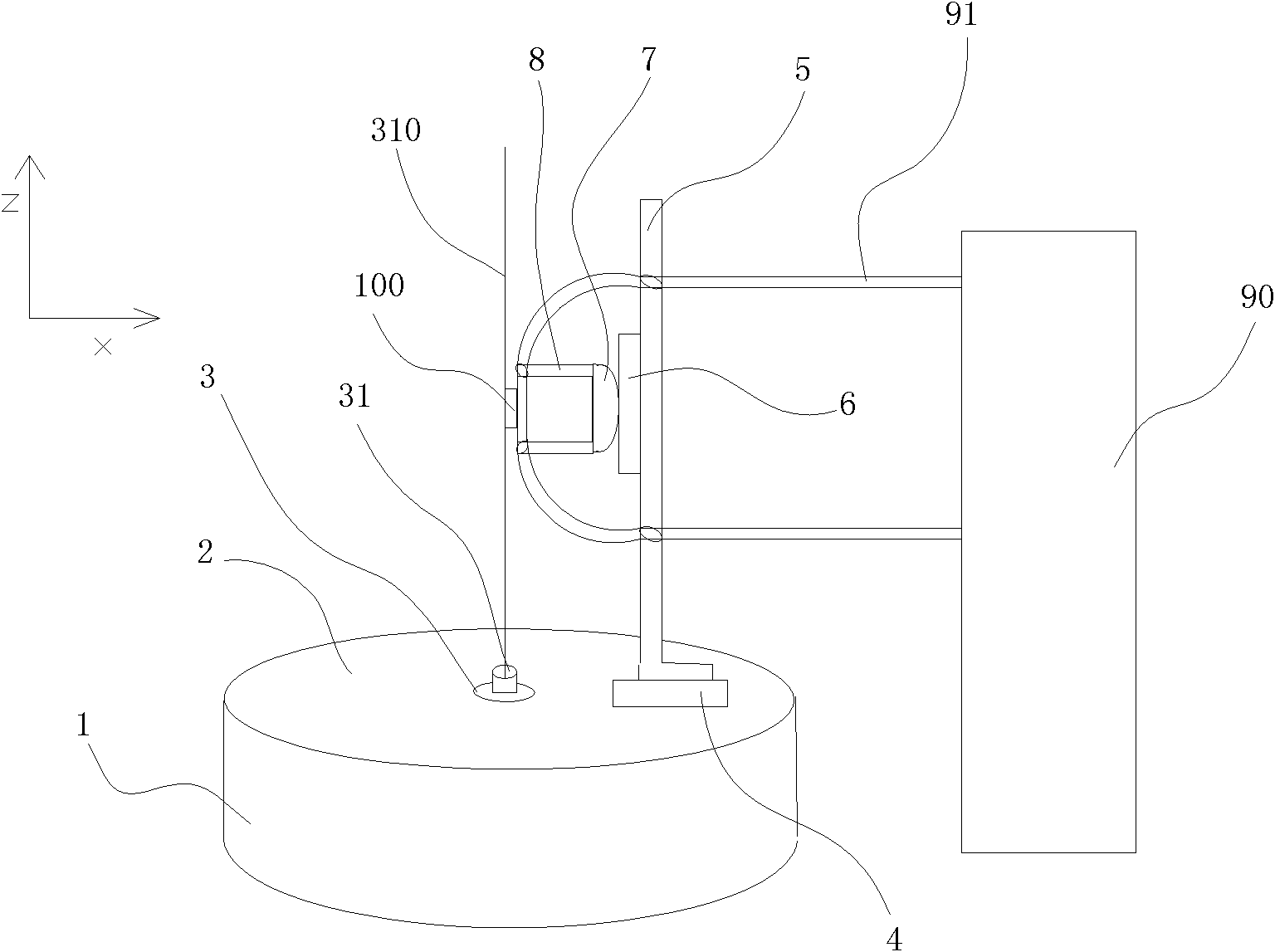

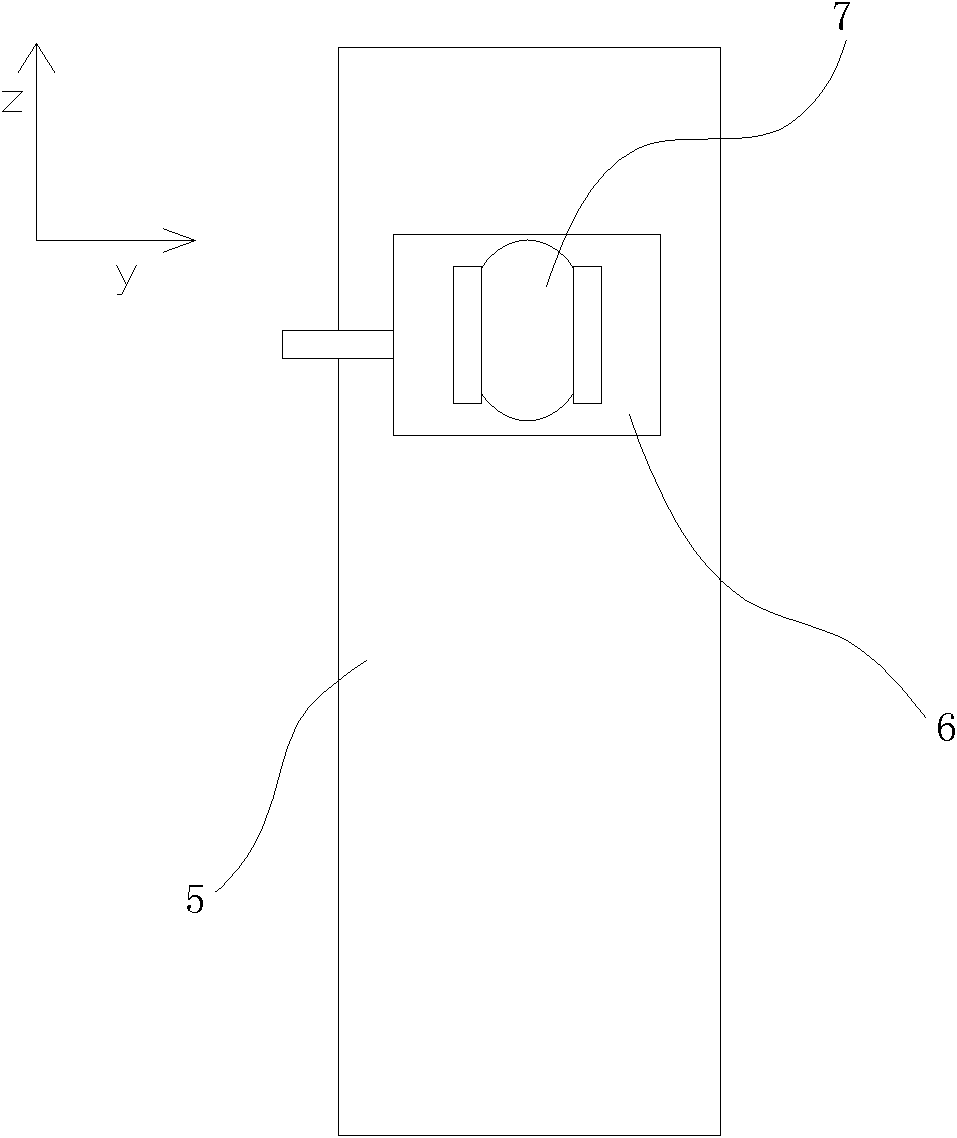

Method and device for measuring vertical divergence angle of high-power laser diode array

InactiveCN102539116AGuaranteed to workGuaranteed collinearSpectrum investigationTesting optical propertiesMeasurement deviceHigh power lasers

The invention discloses a device and a method for measuring the vertical divergence angle of a high-power laser diode array. The method comprises the following steps: calibrating the device for measuring the vertical divergence angle of the high-power laser diode array; and measuring the spectrum intensity vertical to the light-emitting surface of the laser diode array, carrying out difference operation through different revolving angles of a revolving plate under the same spectrum intensity, and further acquiring the vertical divergence angle of the high-power laser diode array. The device and the method for measuring the vertical divergence angle of the high-power laser diode array provided by the invention have the advantages that the measuring device has a collimation system, the vertical divergence angle and the spectrum characteristic of the laser diode array can be measured accurately; and additionally, a water cooling system is introduced according to the invention, the operation of the laser diode at the normal temperature is ensured.

Owner:BEIJING GK LASER TECH

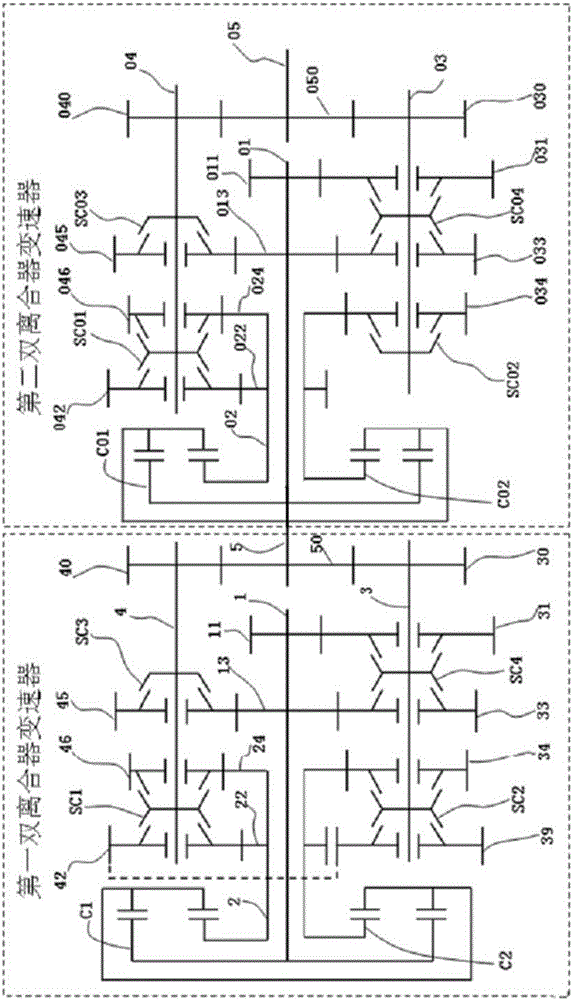

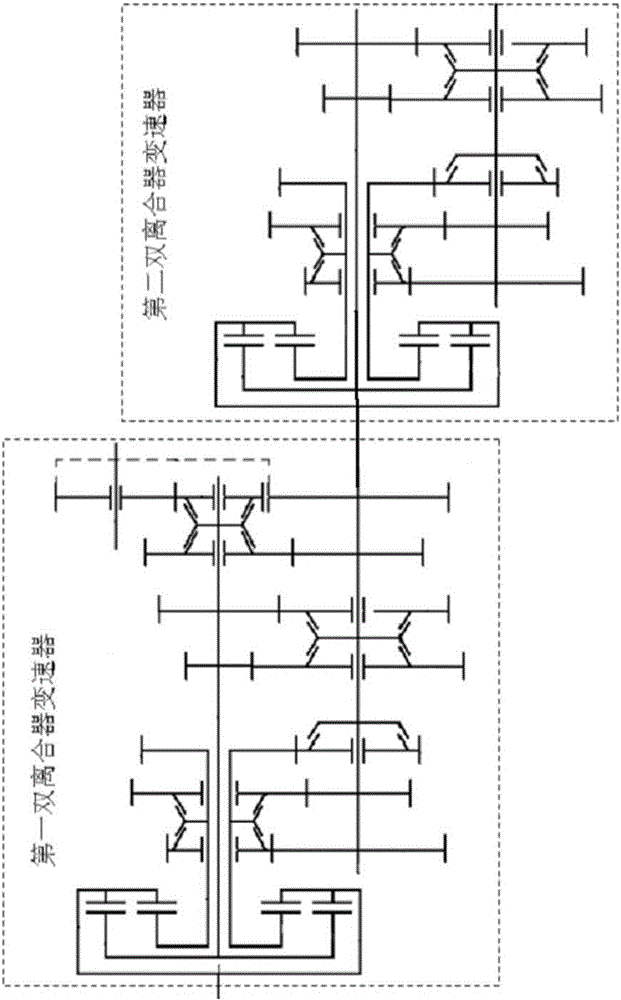

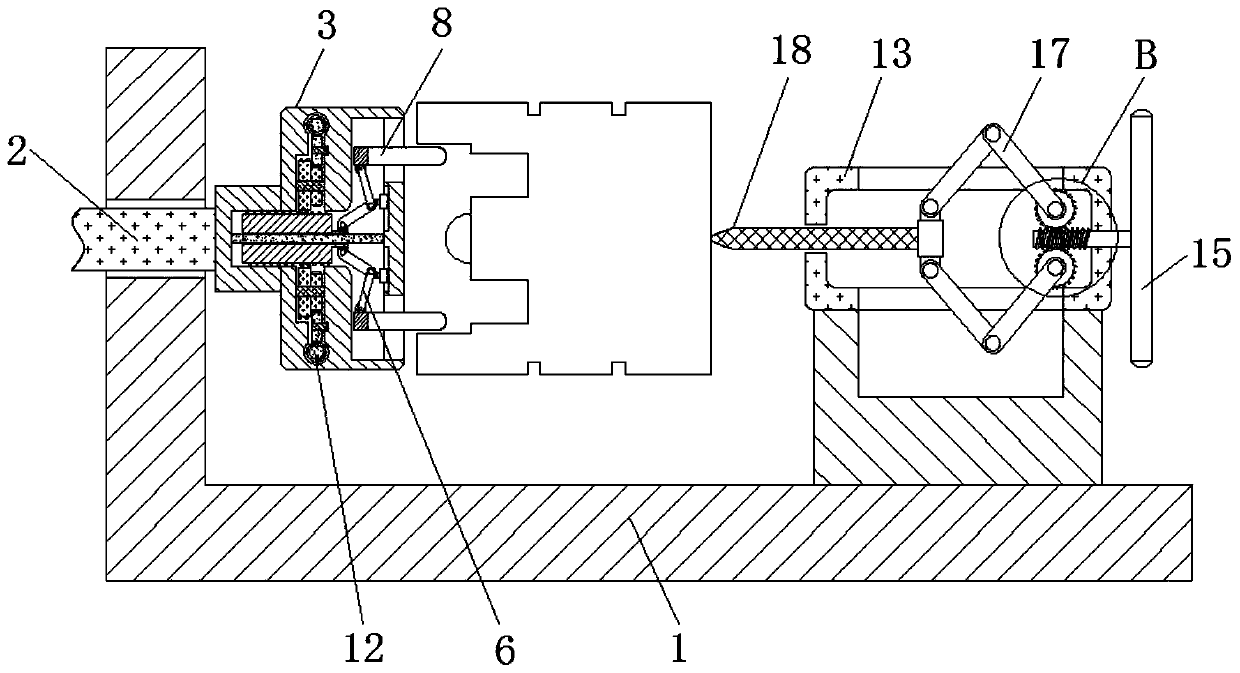

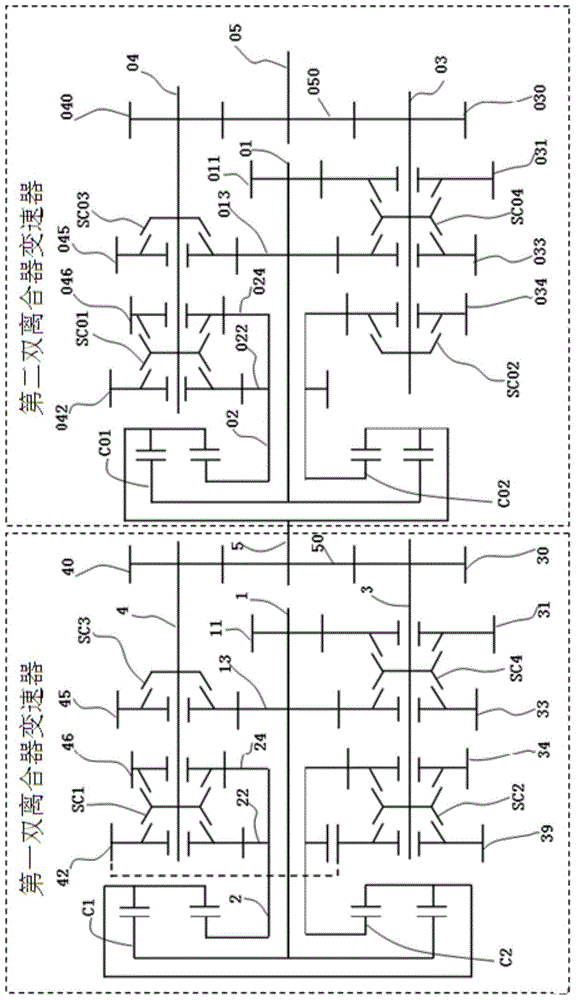

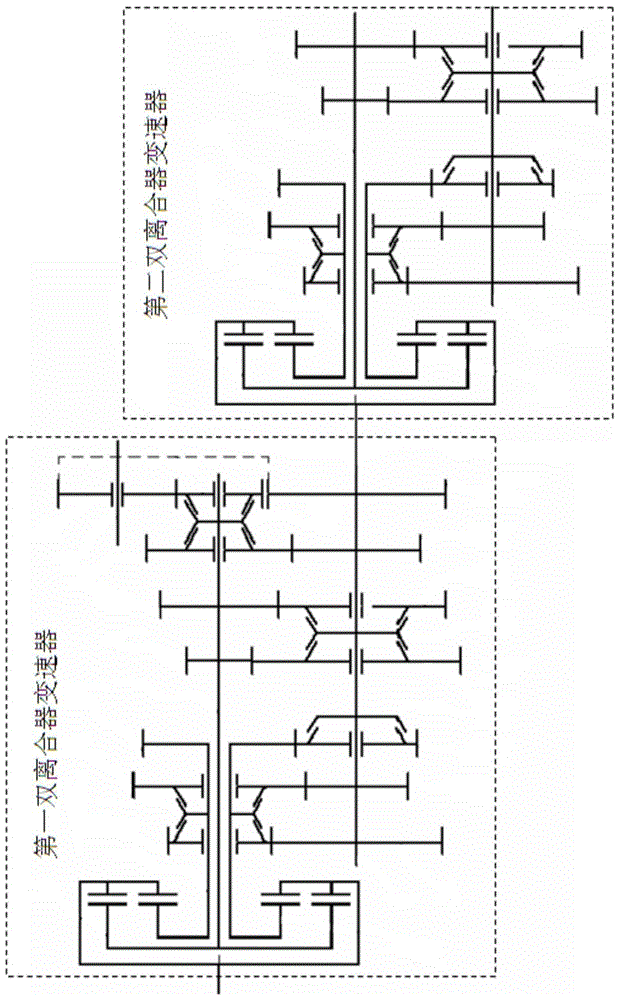

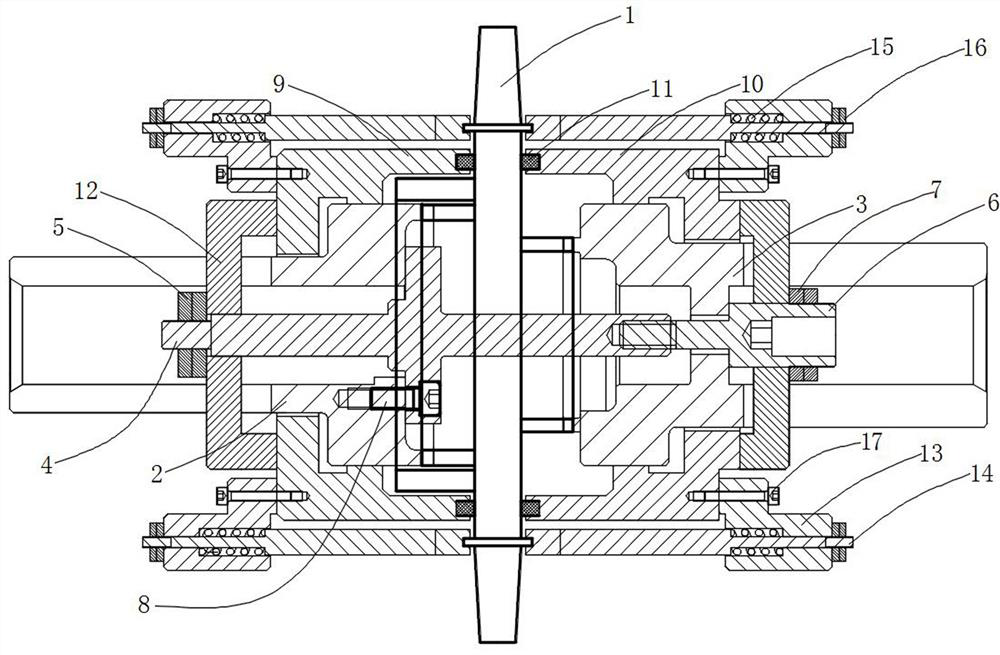

Multi-clutch transmission driving device

InactiveCN106481749AWide range of speed ratioSimple internal structureToothed gearingsGearing controlEngineeringClutch

The invention provides a multi-clutch transmission driving device comprising a first dual-clutch transmission and a second dual-clutch transmission. An output shaft of the first dual-clutch transmission is connected with a shell body of the second dual-clutch transmission. According to the multi-clutch transmission driving device, a multistage clutch structure in one transmission is replaced by the two dual-clutch transmissions, speed ratio range widening is realized, meanwhile the structure is simple, and the reliability is strong.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

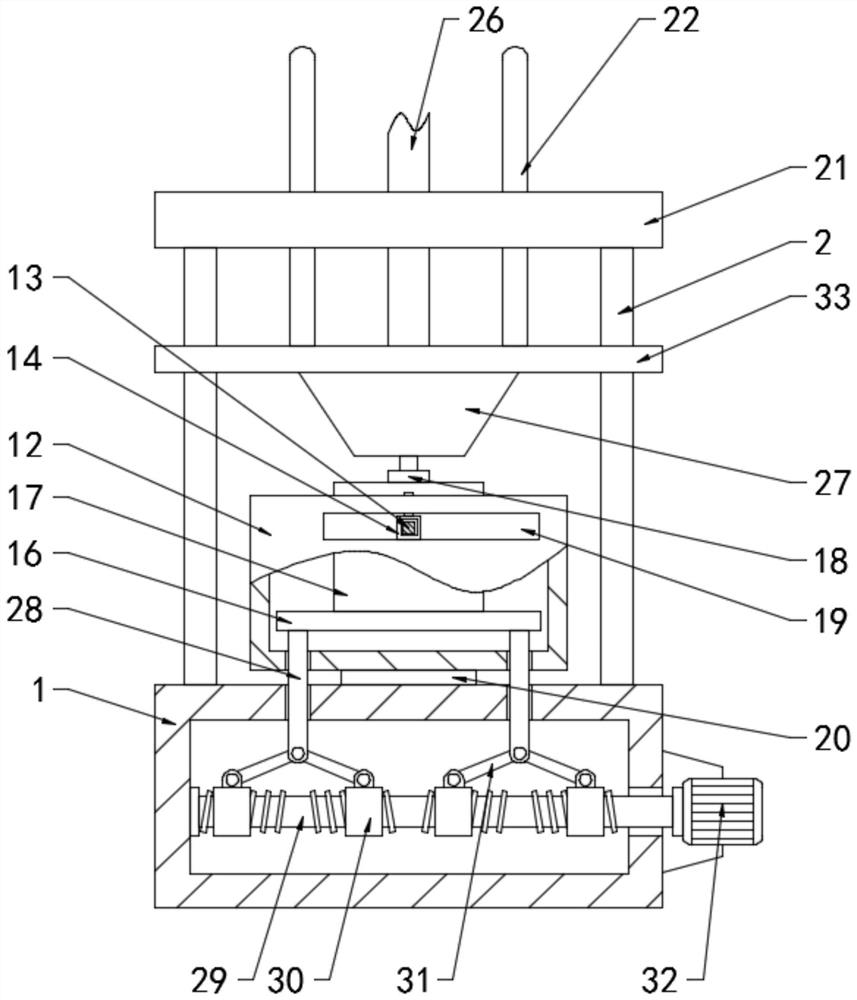

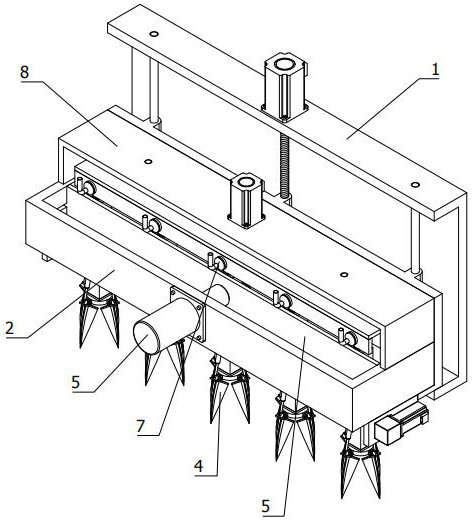

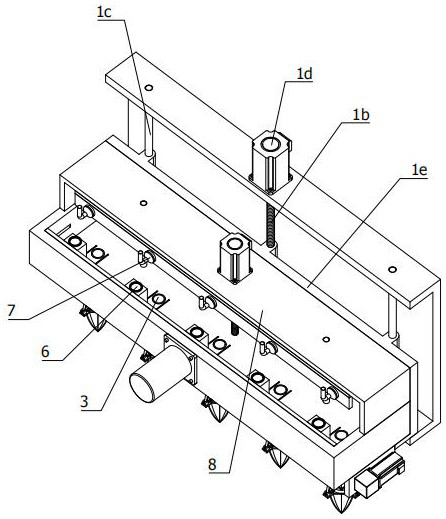

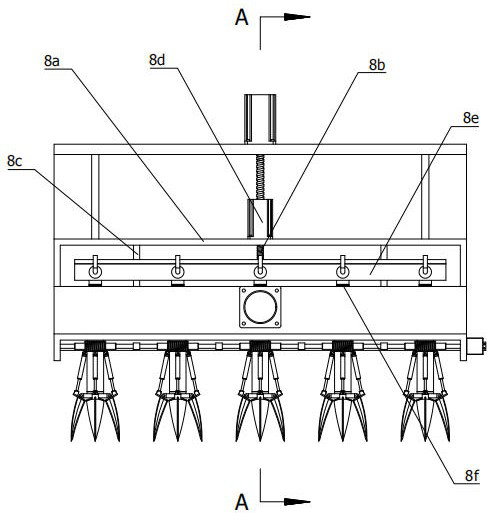

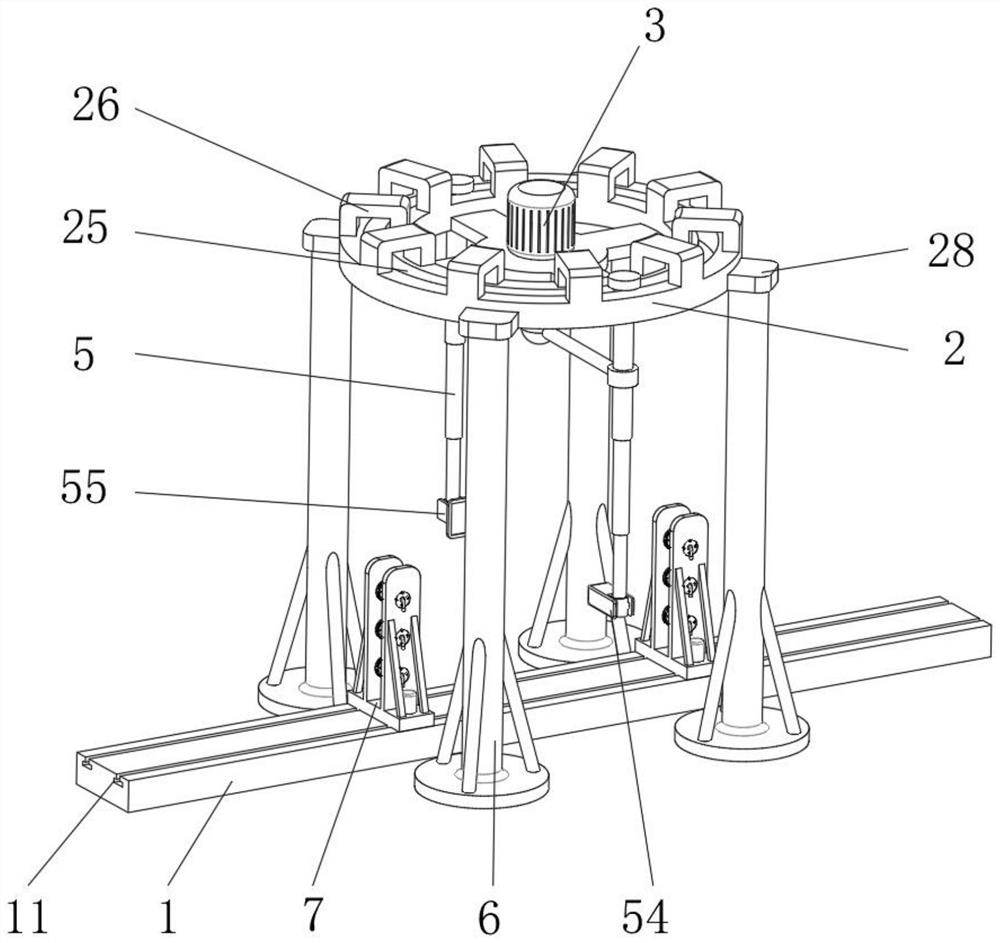

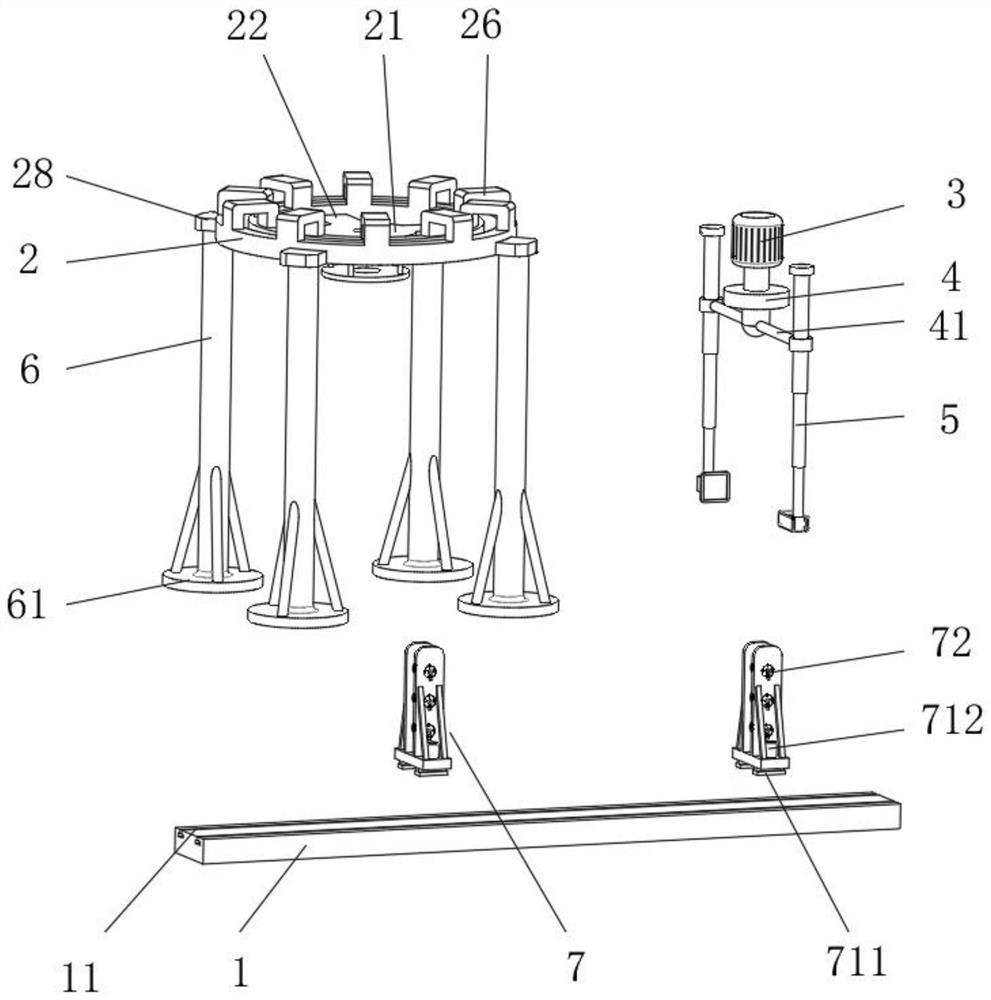

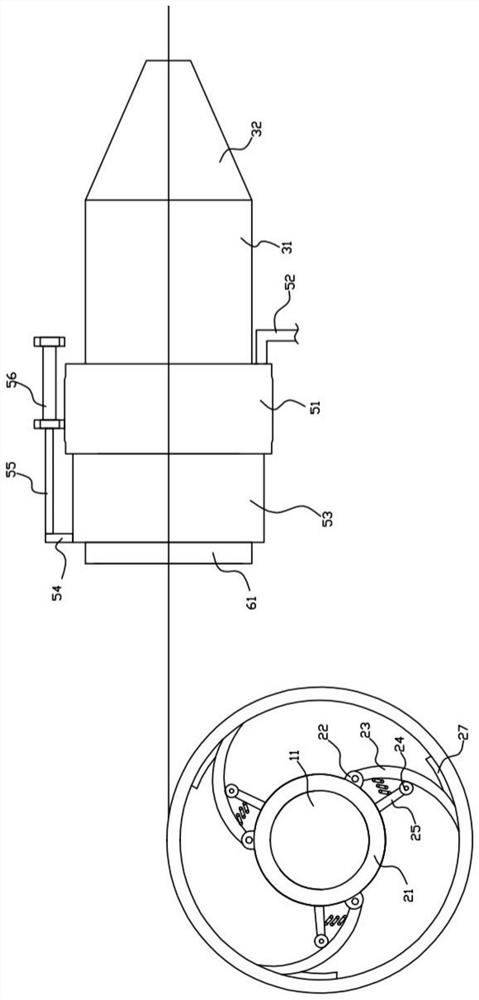

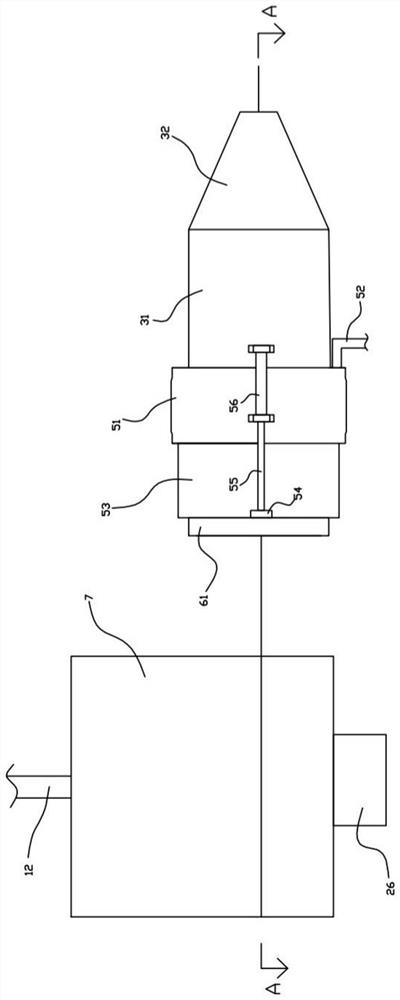

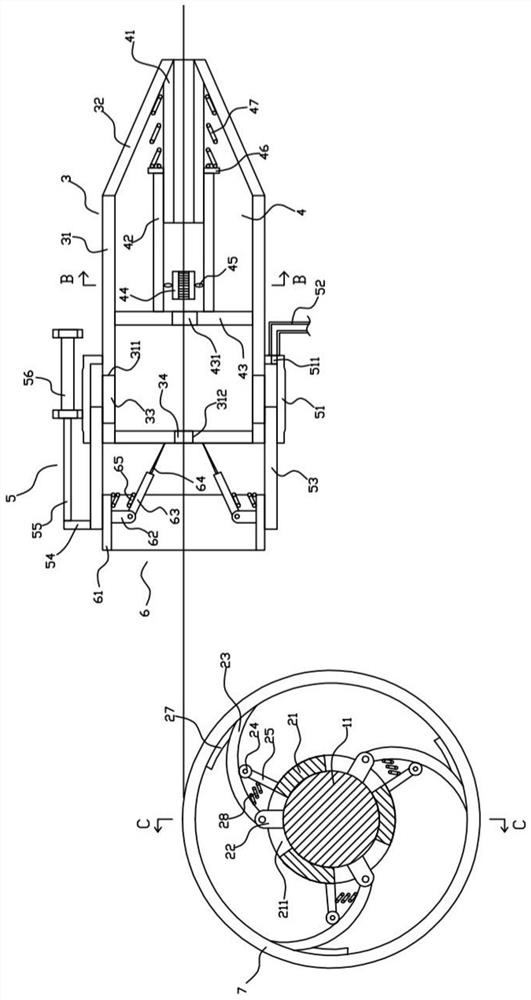

Barren mountain tree planting machine for green tea tree planting

InactiveCN112493081ALarge diameterConvenient whereaboutsPlantingFurrow making/coveringAgricultural scienceGreen teas

The invention relates to the field of tea planting equipment, in particular to a barren mountain tree planting machine for green tea tree planting. The machine comprises a moving mechanism, a liftingmechanism, a workbench, discharging pipes, excavating mechanisms, a pushing mechanism, tea seedling placing cylinders, air injection mechanisms and a butt joint mechanism. The lifting mechanism is mounted on the moving mechanism; the workbench is installed at the working end of the lifting mechanism; the multiple discharging pipes are fixedly installed at the bottom of the workbench; the pluralityof excavating mechanisms are rotatably mounted on the discharging pipes; the pushing mechanism is installed on the workbench; the multiple tea seedling placing cylinders are installed at the workingend of the pushing mechanism, the bottoms of the tea seedling placing cylinders are in butt joint with the top ends of the discharging pipes in the working state, and sliding blocks in sliding connection with the workbench are arranged at the bottoms; the air outlet ends of the multiple air injection mechanisms are installed at the working end of the butt joint mechanism; and the butt joint mechanism is installed on the workbench, and the moving direction of the working end is arranged in the axis direction of the discharging pipes and the tea seedling placing cylinders. The barren mountain tree planting machine is high in working efficiency, stable in structure and capable of saving labor cost.

Owner:贺海兵

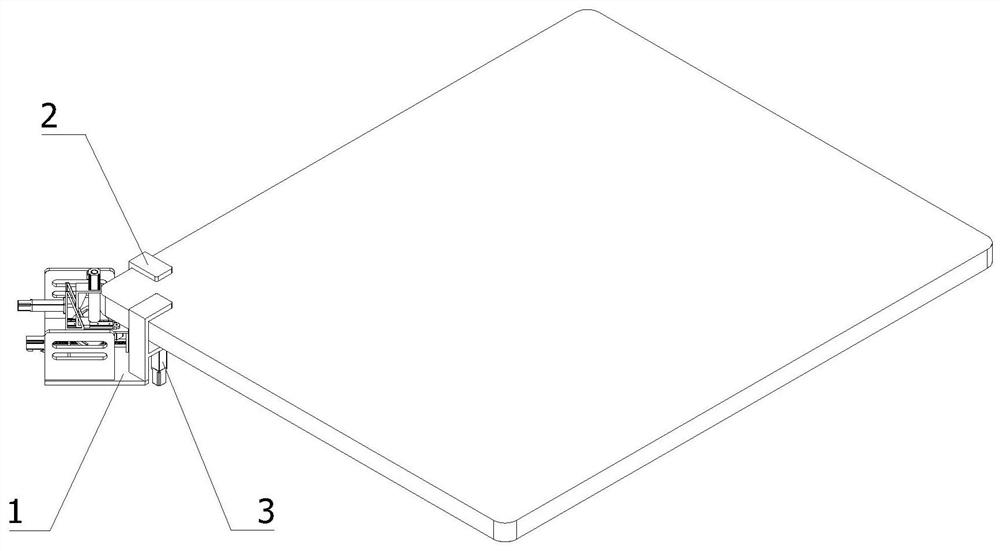

Cable roundness shaping and positioning device

InactiveCN113053591ARealize regulationGuaranteed collinearInsulating conductors/cablesControl theoryElectric cables

Owner:武汉新天地电工科技有限公司

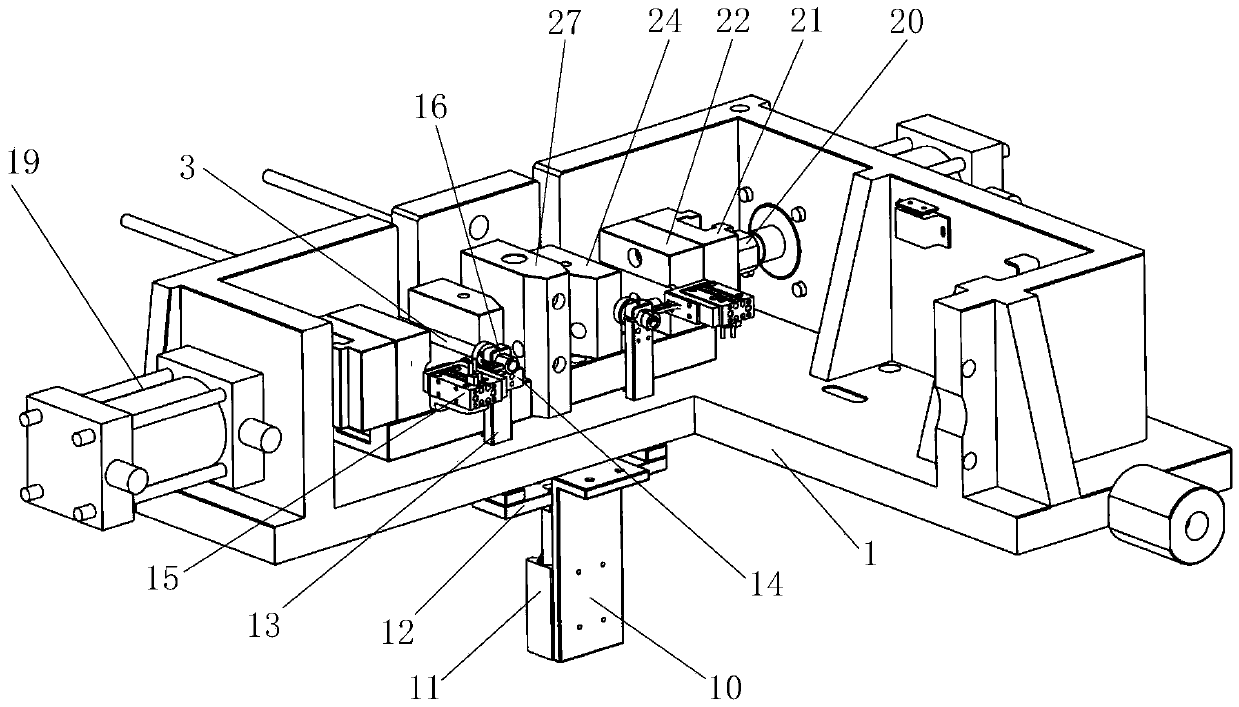

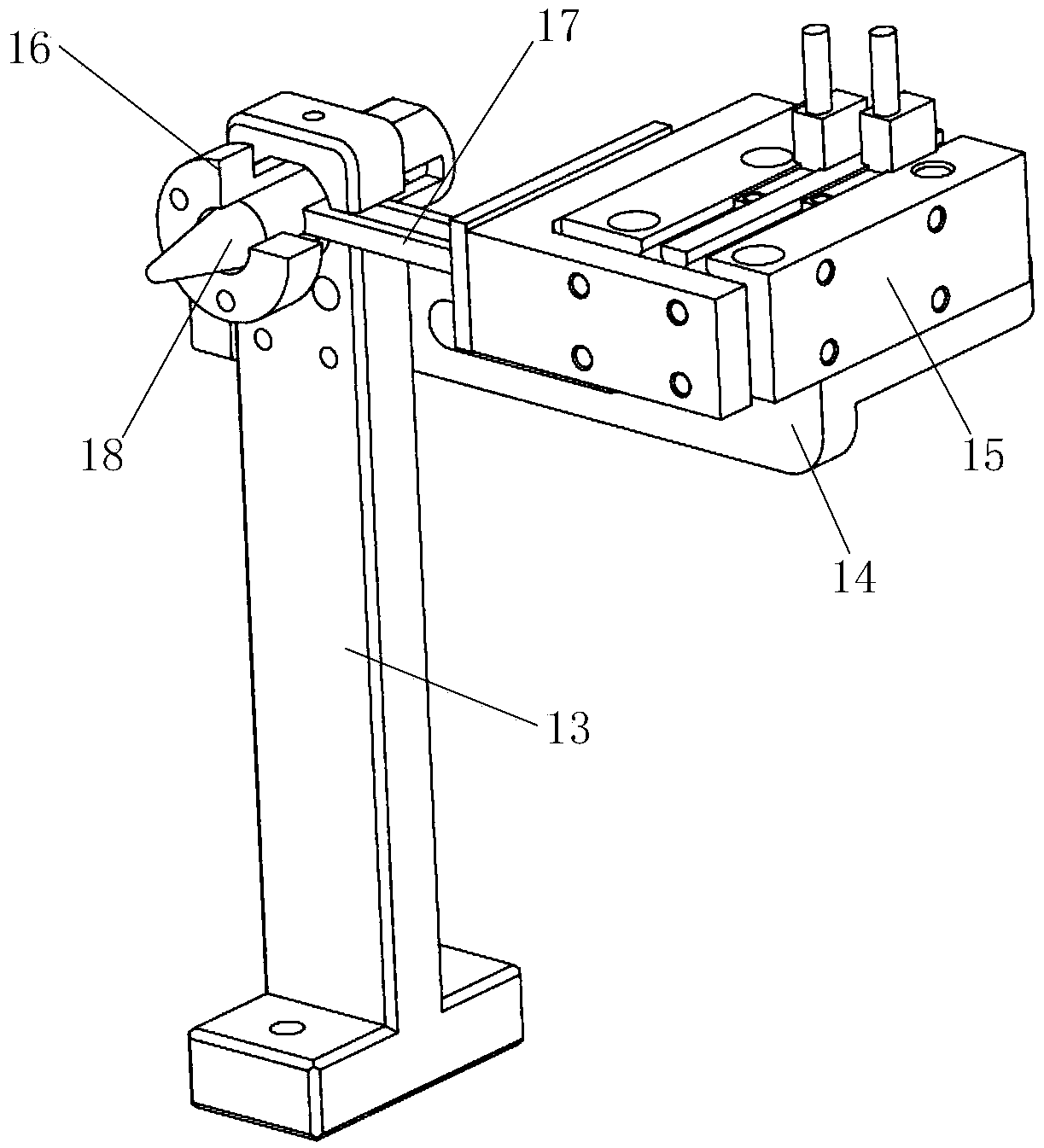

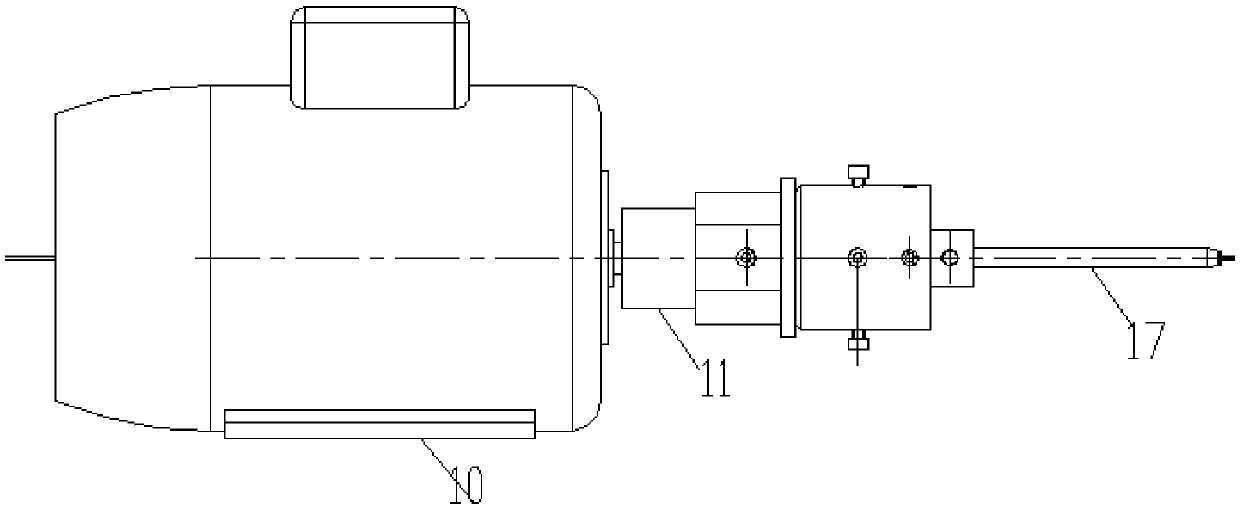

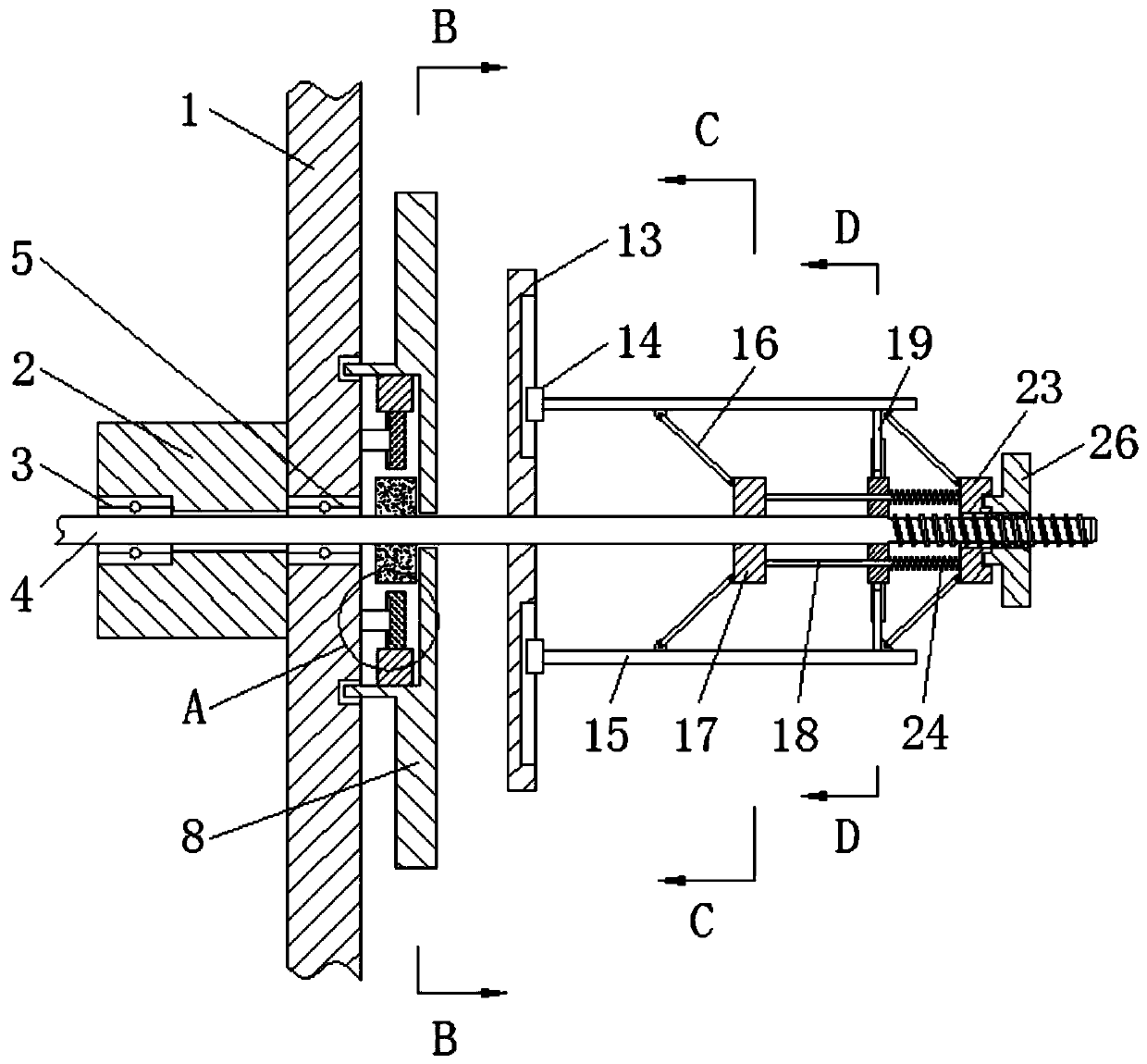

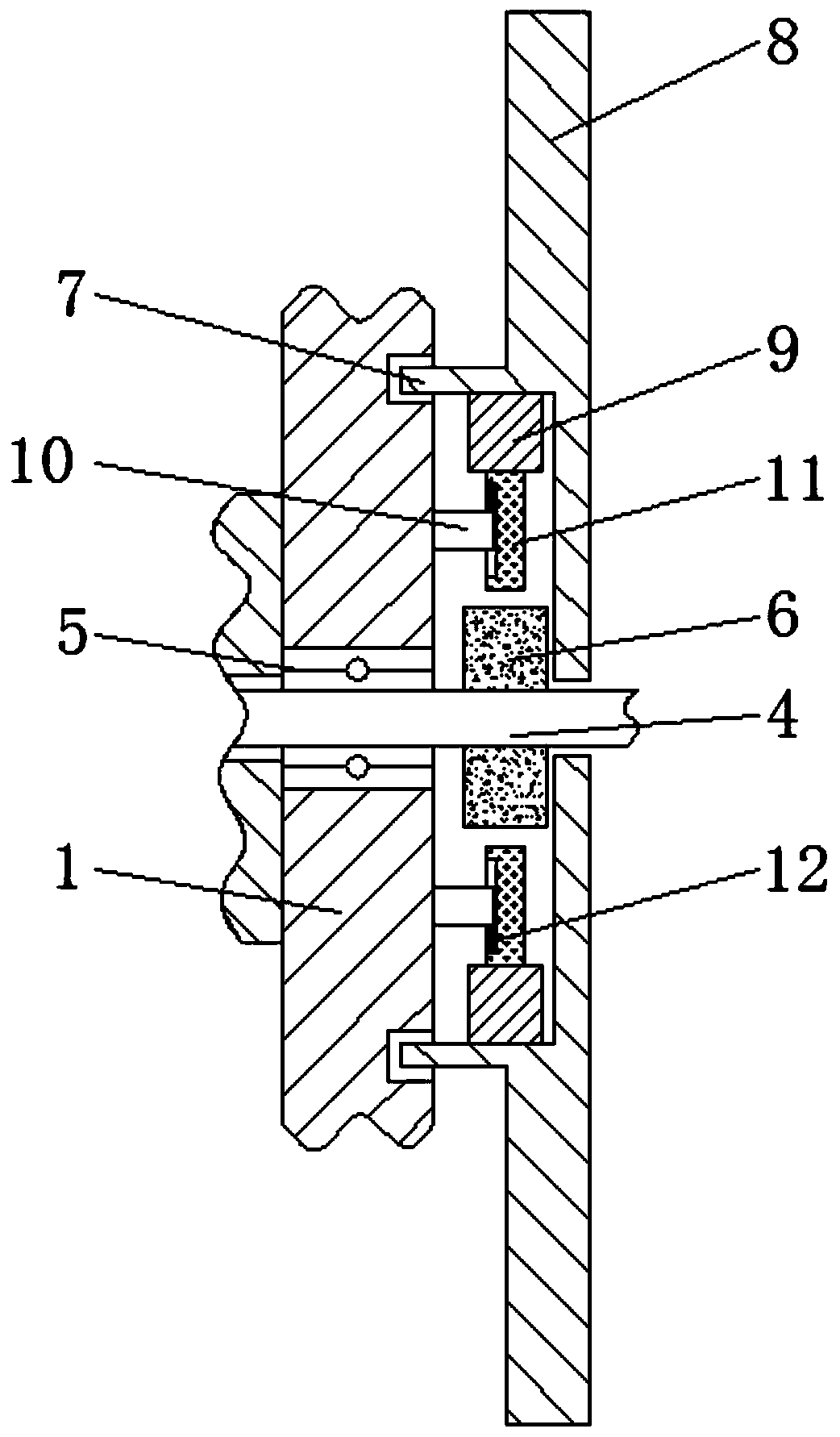

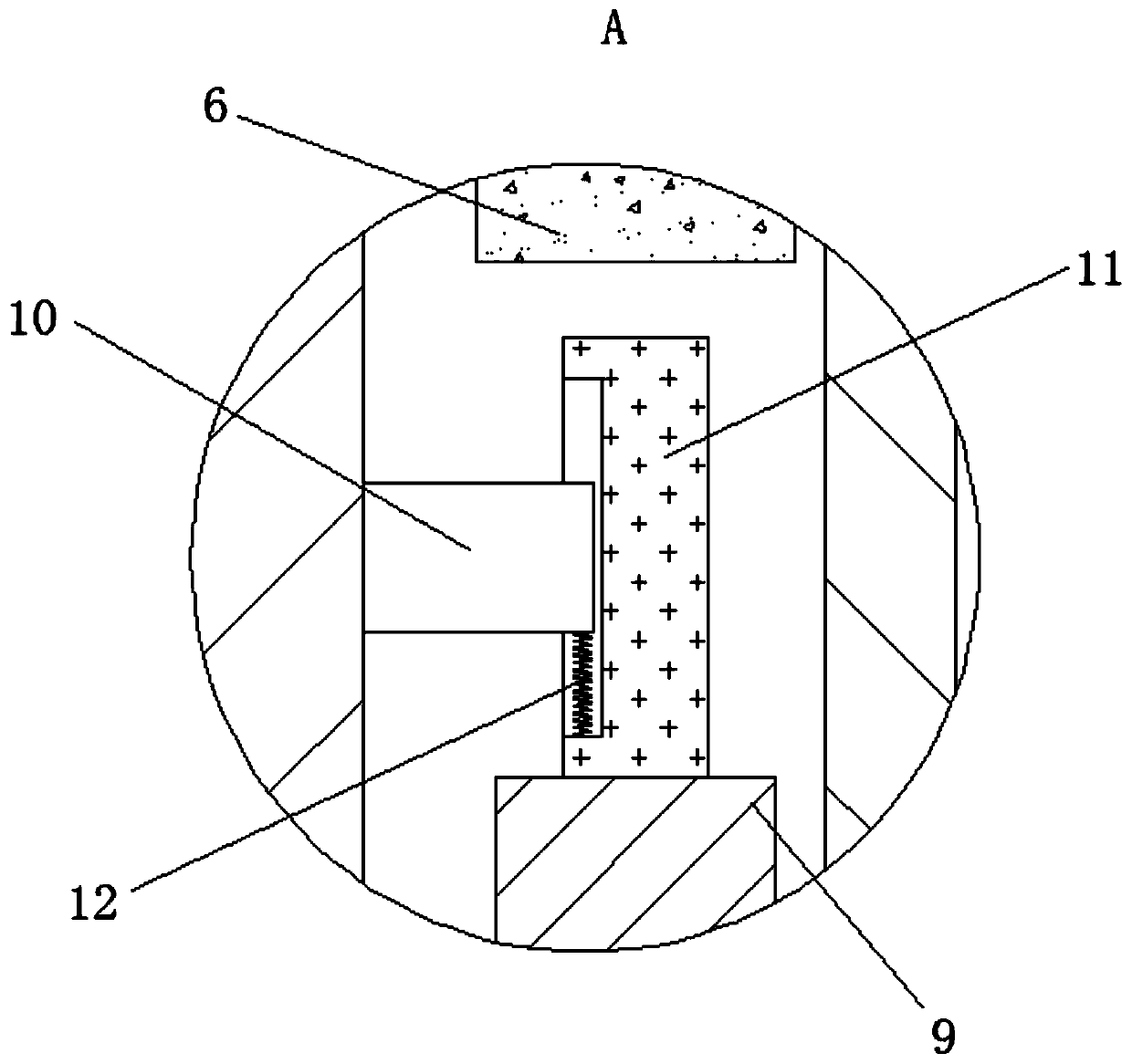

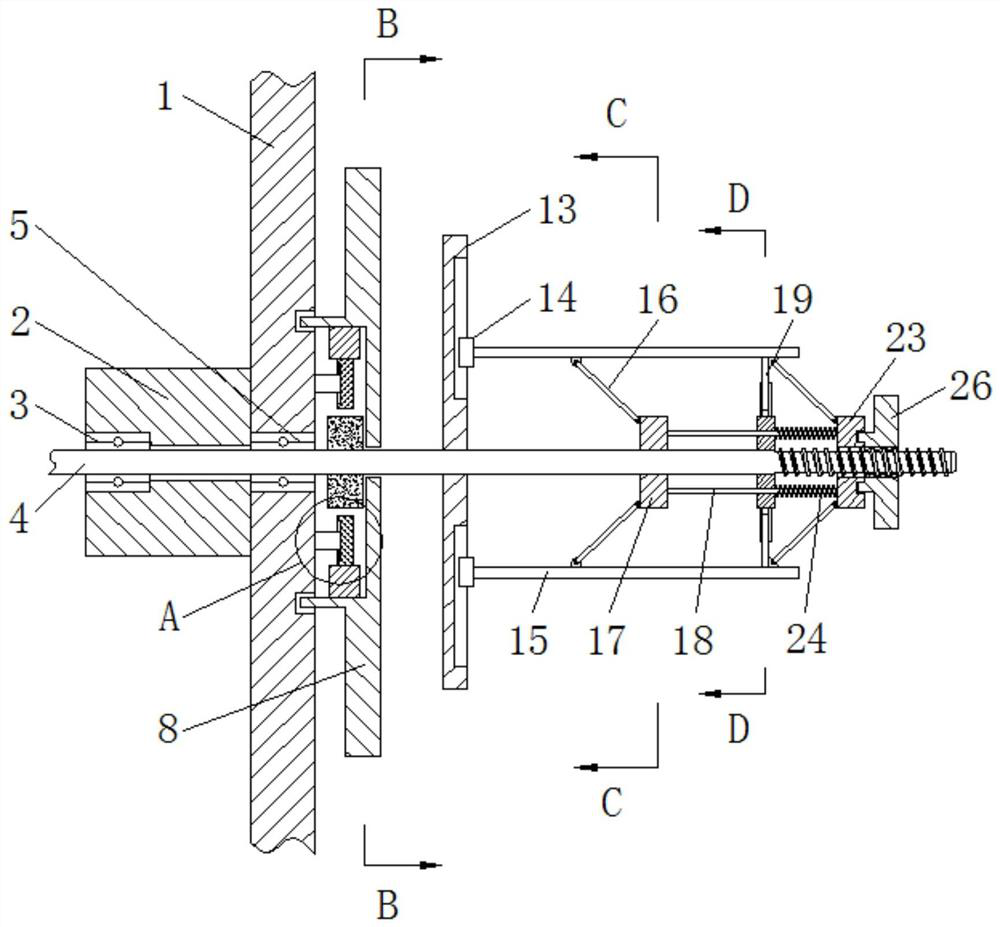

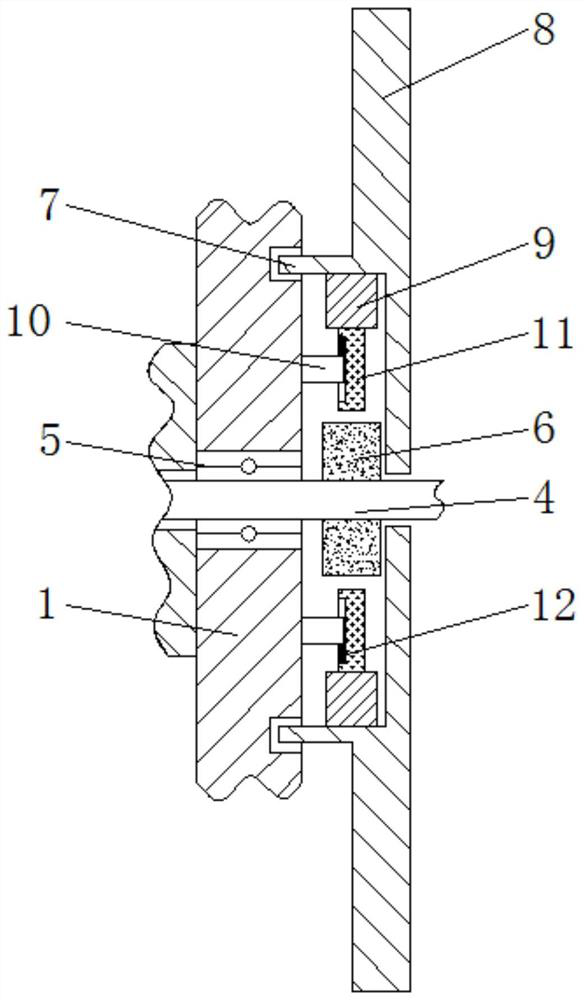

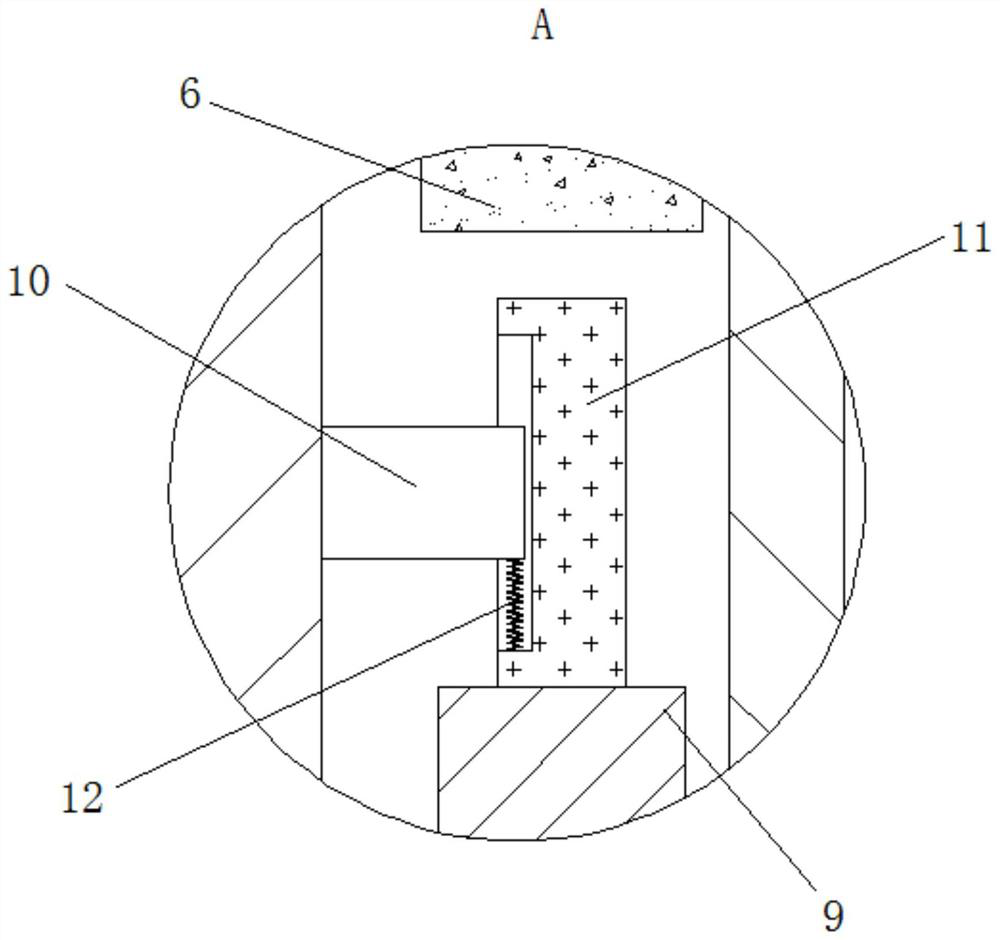

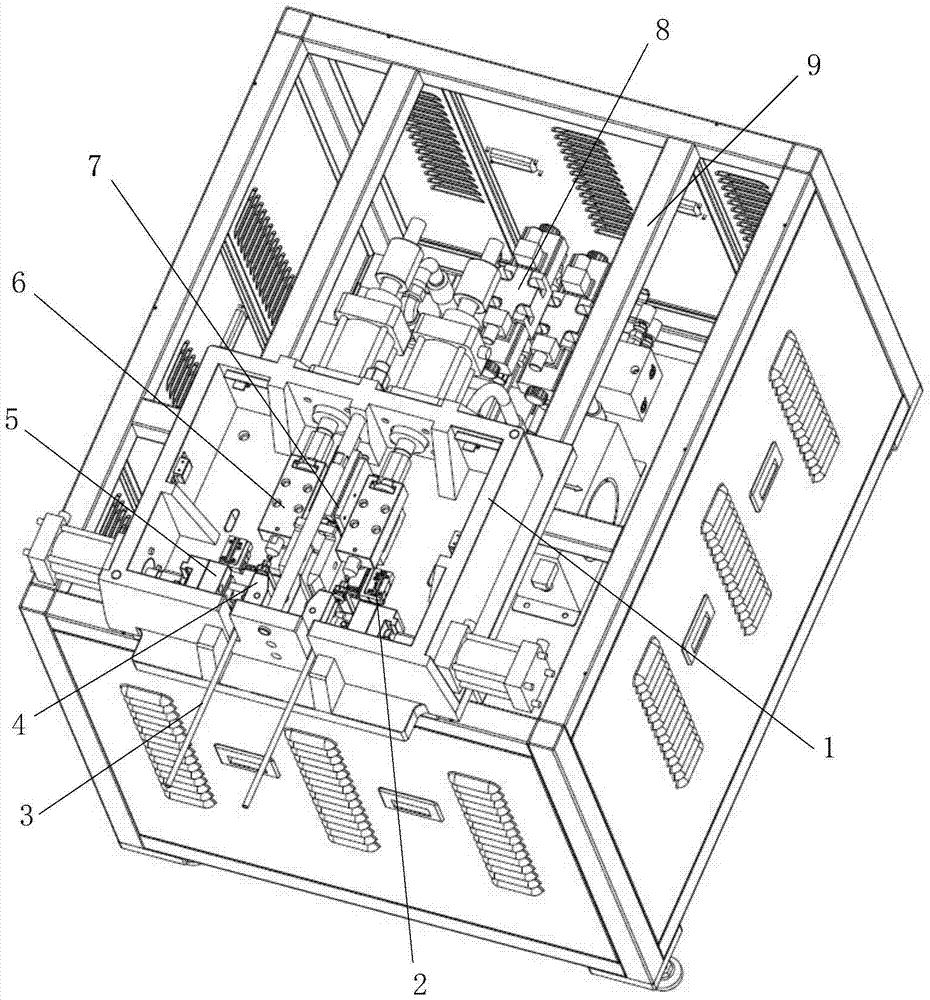

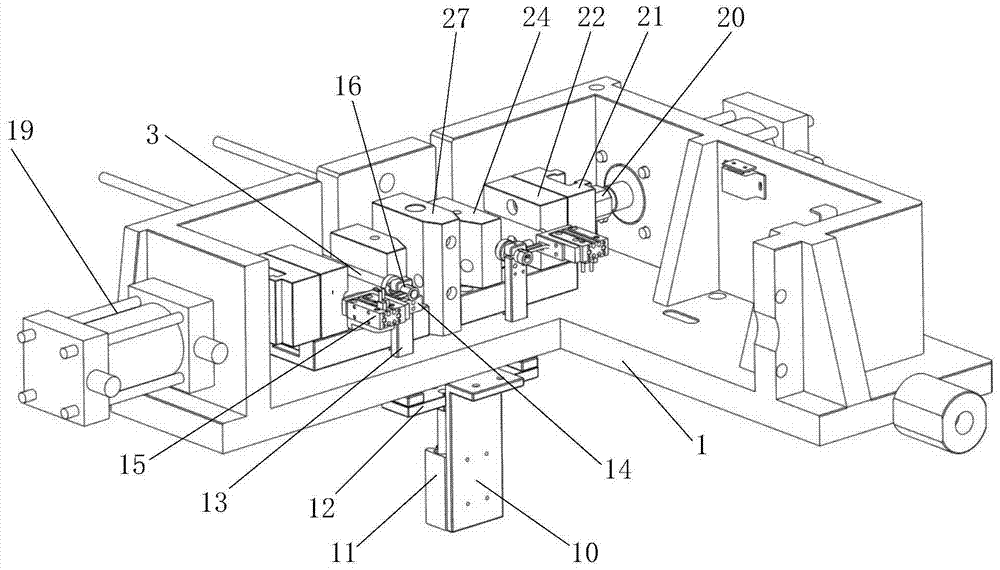

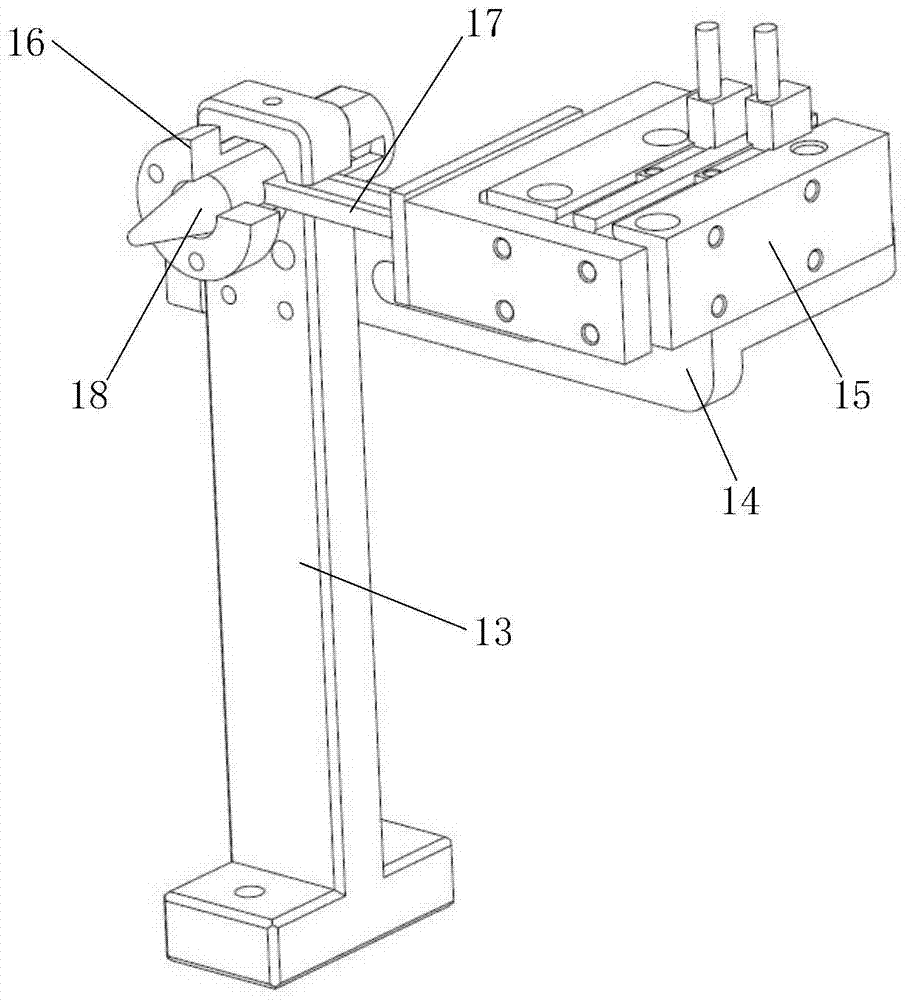

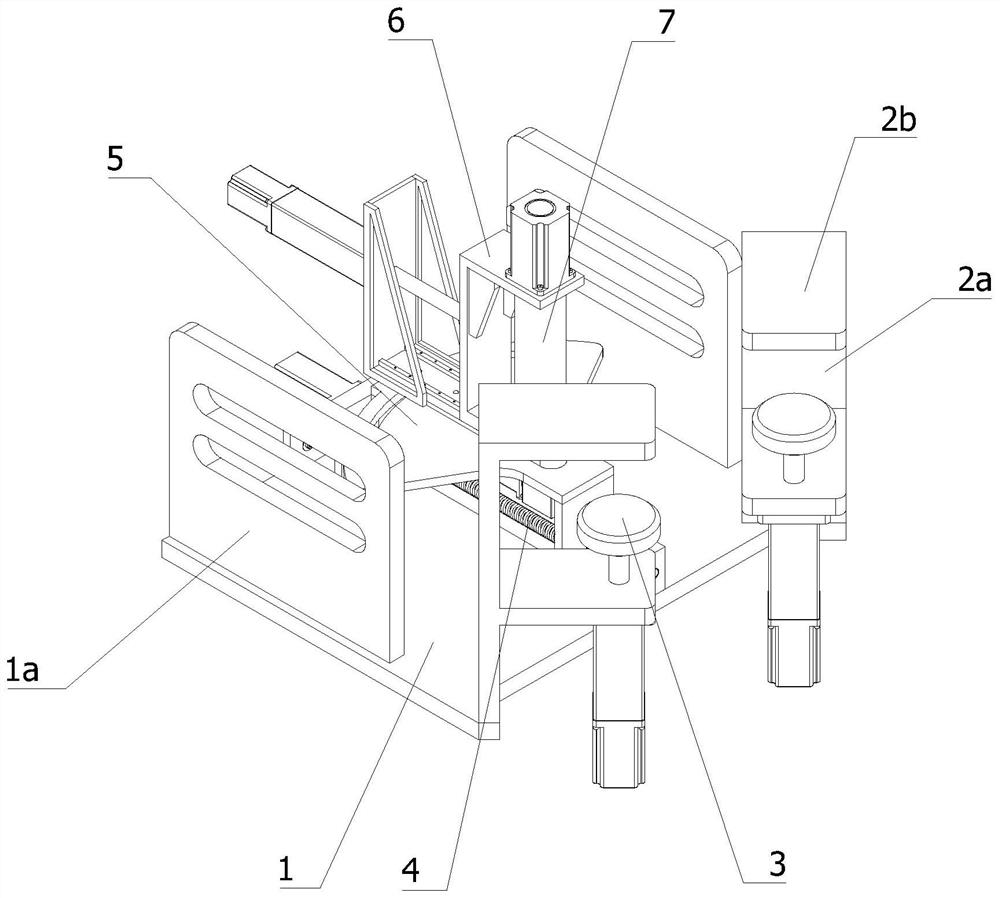

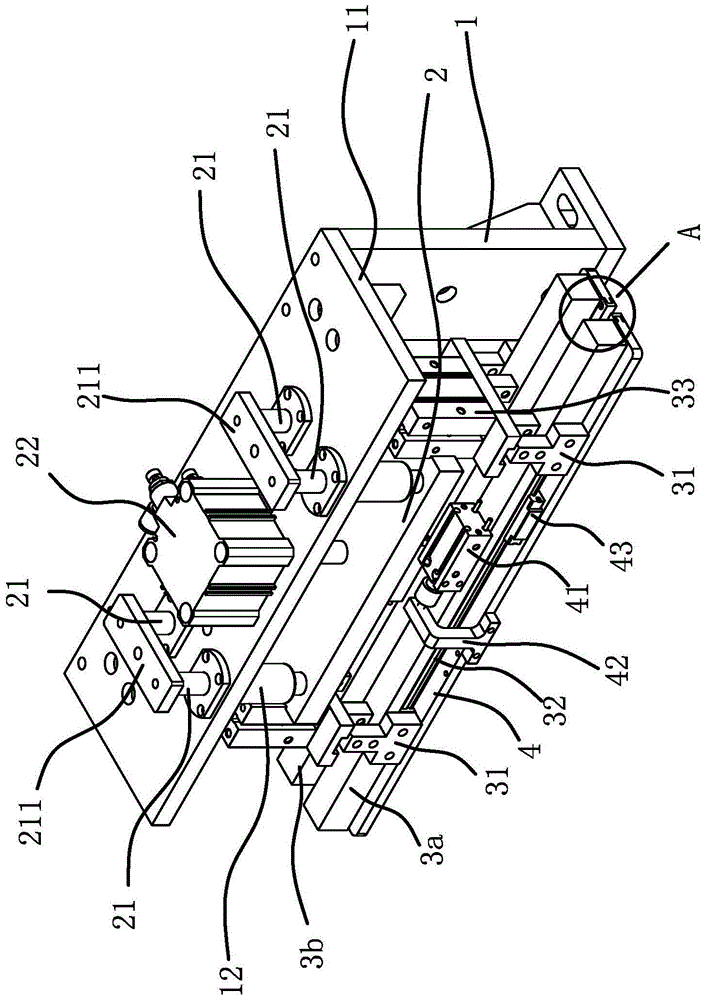

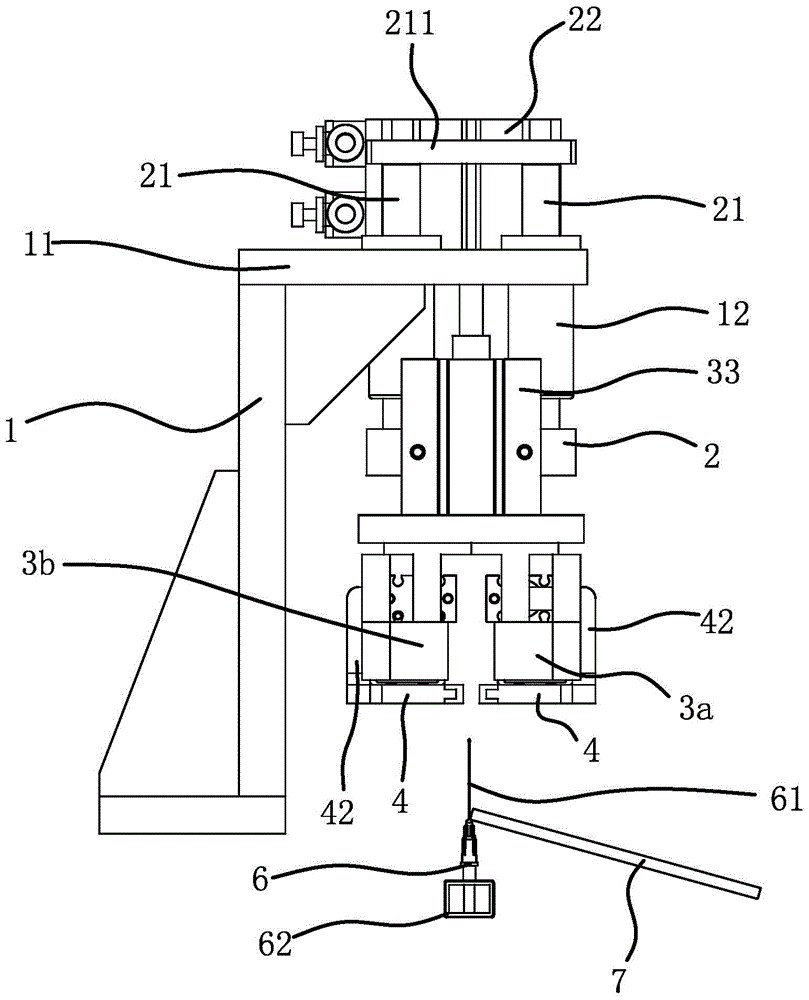

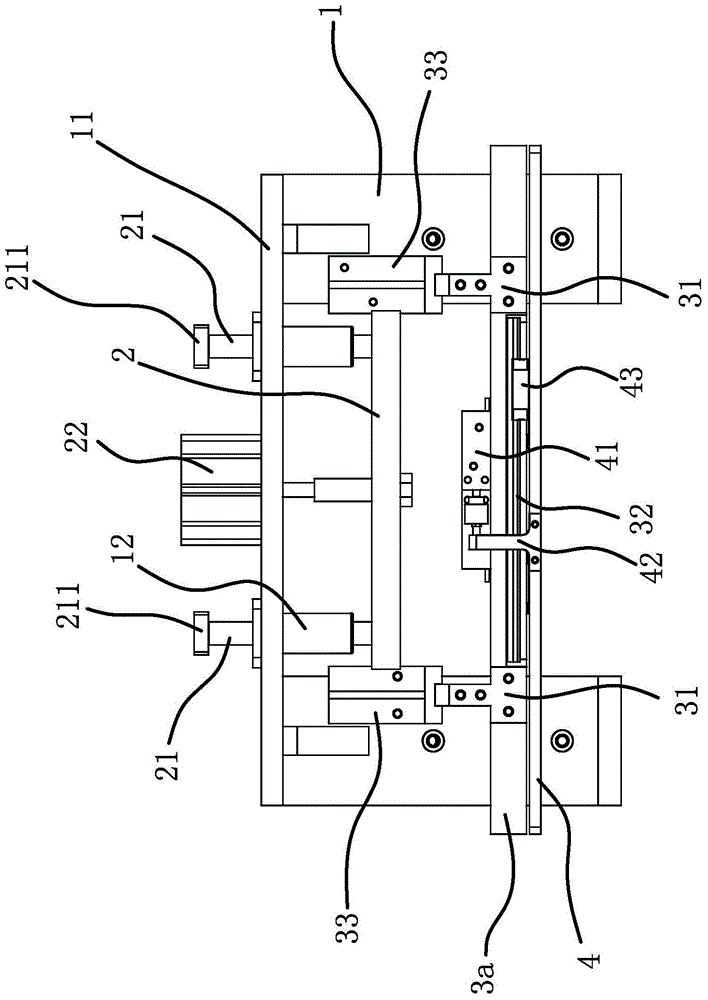

Automatic flaring machine

ActiveCN105499416AGuaranteed collinearImprove positioning accuracyMetal-working feeding devicesPositioning devicesEngineeringElectrical and Electronics engineering

The invention discloses an automatic flaring machine which comprises a machine base, a flaring fixed die assembly, a flaring movable die assembly, a flaring and stamping device and a positioning device, wherein the flaring movable die assembly is matched with the flaring fixed die assembly to clamp connection pipes; the flaring and stamping device is used for conducting flaring on the connection pipes; the positioning device can make the axes of the connection pipes coincide with the axis of a punch of the flaring and stamping device; the flaring fixed die assembly, the flaring movable die assembly, the flaring and stamping device and the positioning device are arranged on the machine base. According to the automatic flaring machine, the positioning device is additionally arranged, it is guaranteed that the axels of the connection pipes are collinear with the axis of the punch of the flaring and stamping device, and the flaring fixed die assembly and the flaring movable die assembly clamp the connection pipes; compared with the prior art that the connection pipes are manually positioned, positioning accuracy of the connection pipes is effectively improved, so that the percentage of pass of finished products is raised, and consistency of the finished products is improved; the production cost of the finished products is further lowered; meanwhile, automatic flaring is achieved, production efficiency is improved, and labor intensity is lowered.

Owner:GREE ELECTRIC APPLIANCES INC

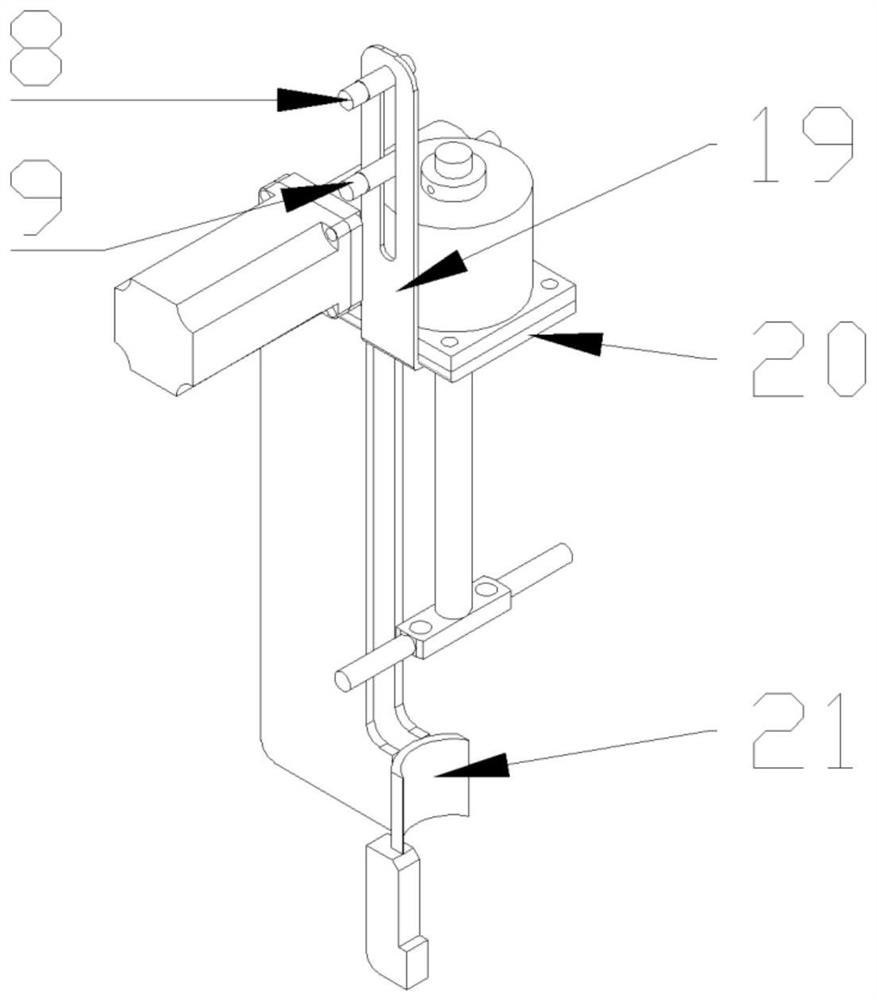

Screw tightening assembly and tightening device

The invention provides a screw tightening assembly and a tightening device and relates to the technical field of engineering machinery. The screw tightening assembly comprises a transition shaft, a fixing shaft and a screwdriver; a groove is formed in the transition shaft; the fixing shaft is disposed in the groove; the screwdriver is disposed in the fixing shaft; and a self-aligning ball bearingis disposed between the fixing shaft and the transition shaft. In the screw tightening assembly provided by the invention, the screwdriver is disposed in the fixing shaft, and the self-aligning ball bearing is disposed between the fixing shaft and the transition shaft. The self-aligning function is achieved through the self-aligning ball bearing so as to prevent errors, the colinearity of the rotation axis of the screwdriver can be guaranteed, and the advantages of good using effect and simple structure are achieved.

Owner:HERON INTELLIGENT EQUIP CO LTD

Automatic centering yarn drum positioning device for twisting machine

The invention relates to the technical field of textile fabrics, and discloses an automatic centering yarn drum positioning device for a twisting machine. The device comprises a twisting machine body;the exterior of the twisting machine body is fixedly connected with a fixed shaft sleeve; the interior of the fixed shaft sleeve is fixedly connected with a first bearing; the interior of the first bearing is fixedly connected with a rotating shaft; the exterior of the rotating shaft is fixedly connected with a second bearing; the exterior of the rotating shaft is fixedly connected with a brake disc; the exterior of the twisting machine body is rotationally connected with a brake ring; the exterior of the brake ring is fixedly connected with a brake rotating wheel; the interior of the brake ring is fixedly connected with a convex block; the exterior of the twisting machine body is fixedly connected with a fixed block; and the exterior of the fixed block is connected with a brake sliding block in a sliding mode. A longitudinal fixed pay-off drum is changed into a transverse fixed pay-off drum through cooperative use of the rotating shaft and a positioning rod, so that the friction between threads and the pay-off drum is avoided and reduced, the threads are prevented from being damaged, and the quality of the threads is guaranteed.

Owner:南通鑫唐纺织印染有限公司

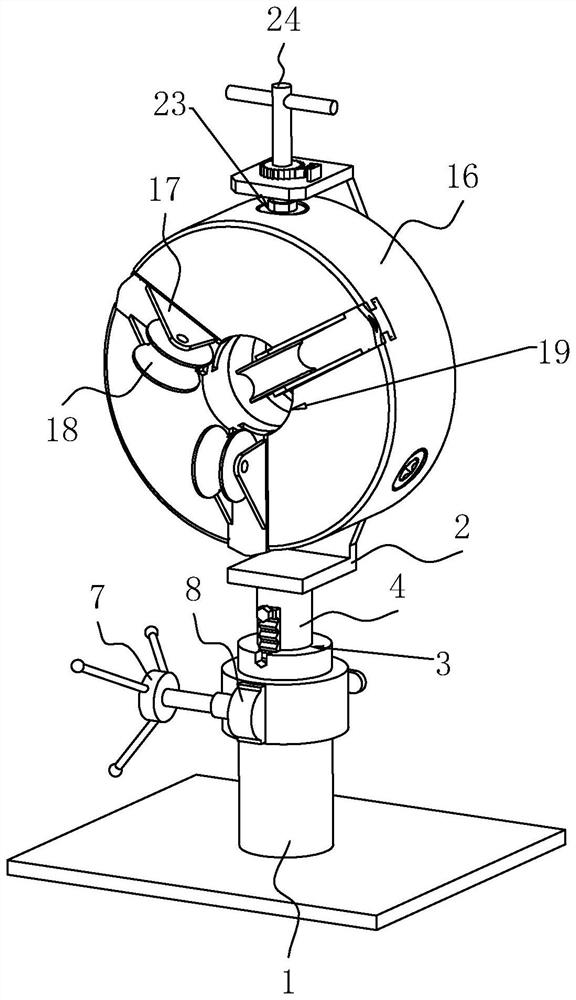

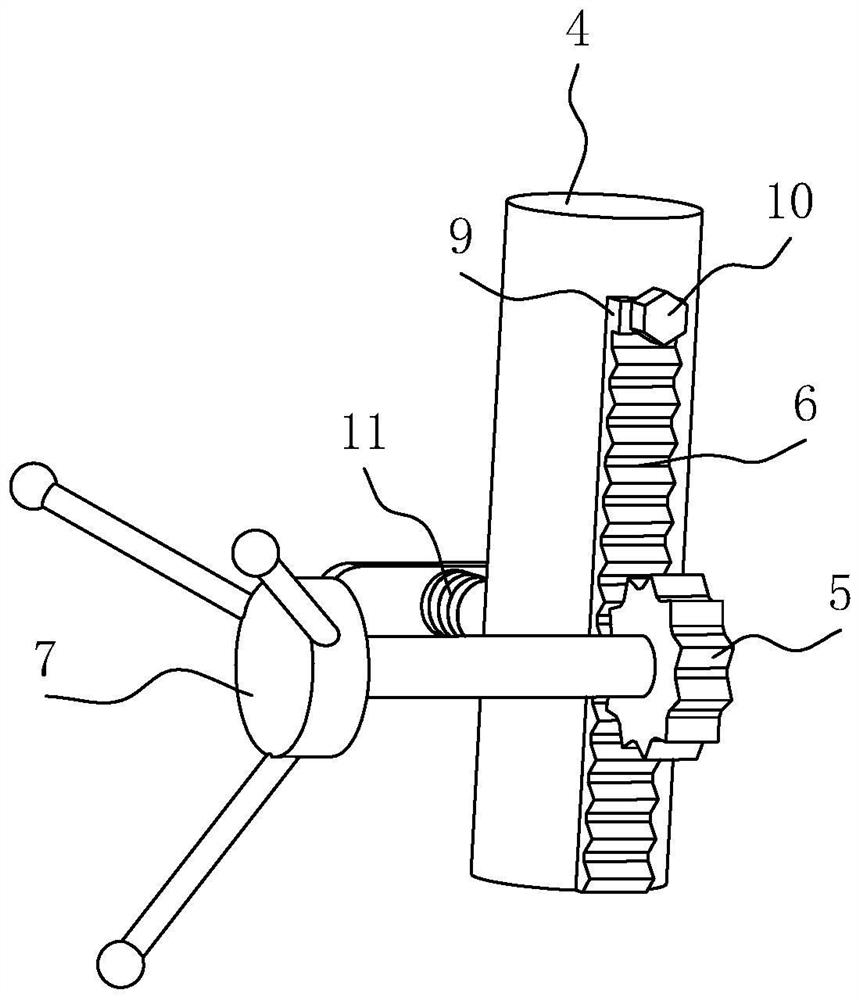

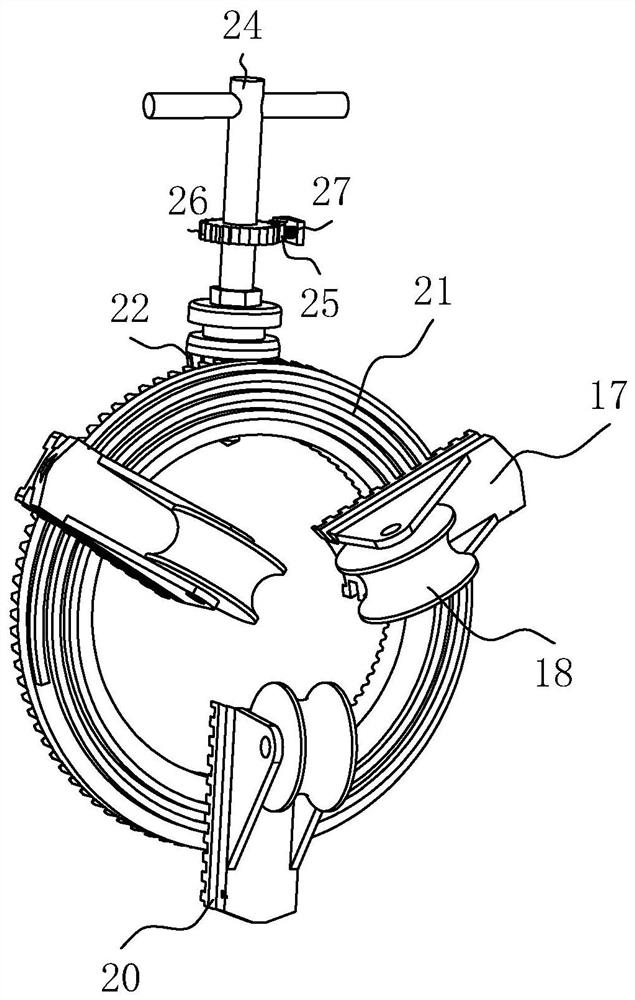

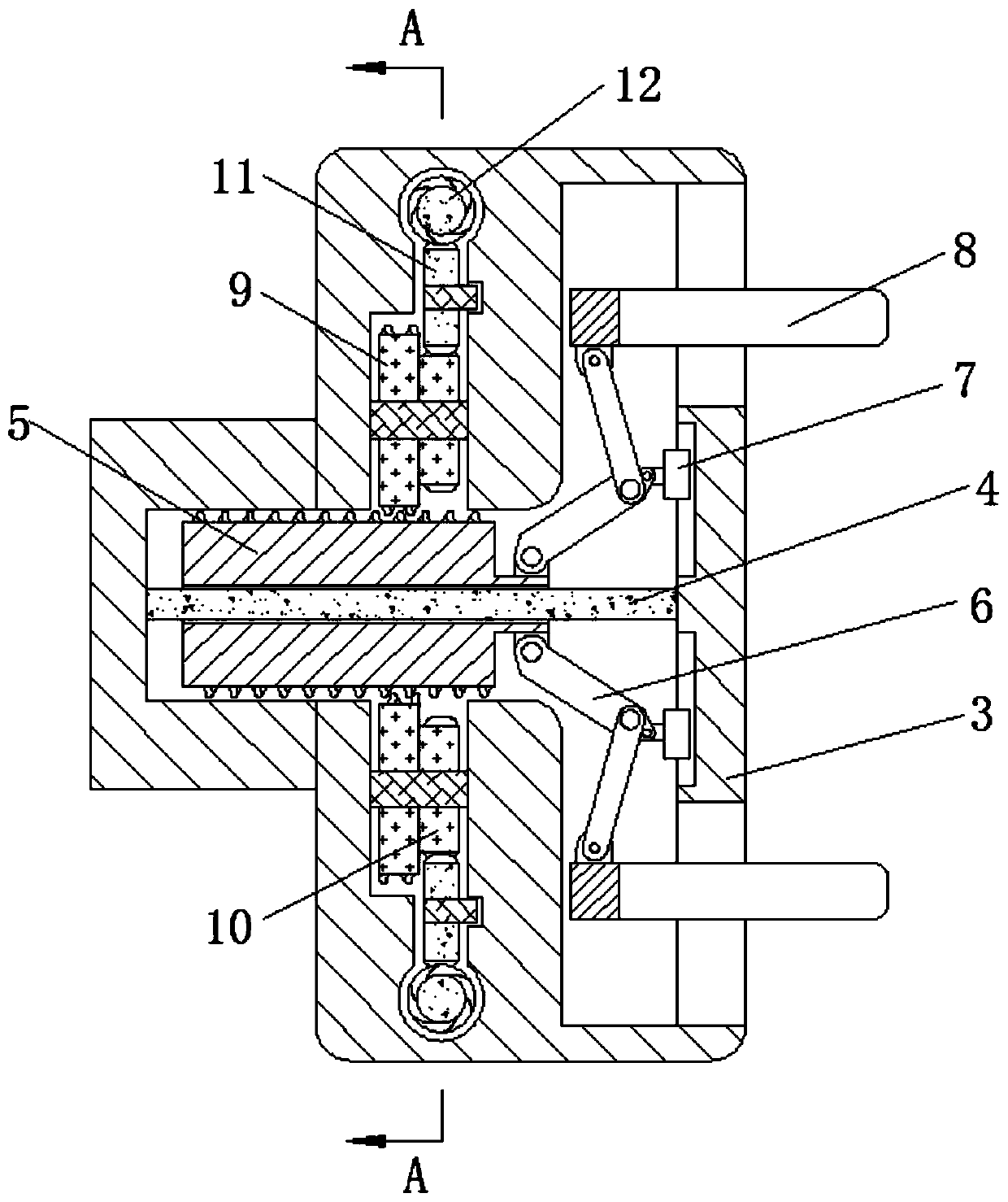

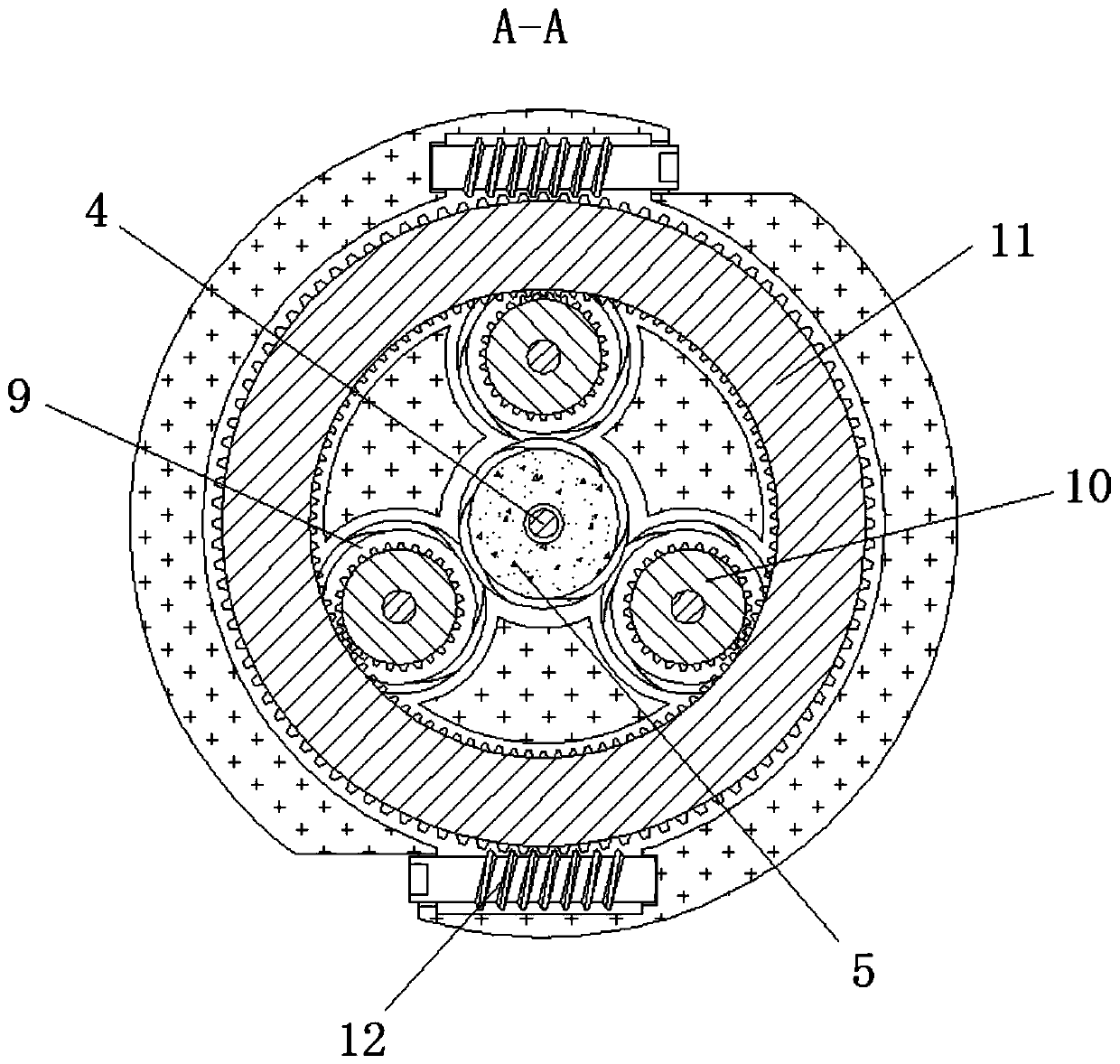

Piston circumferential surface machining fixing device utilizing connecting rod motion principle

InactiveCN111571273AImprove processing efficiencyQuality improvementWork clamping meansPositioning apparatusEngineeringScrew thread

The invention relates to the technical field of pistons, and discloses a piston circumferential surface machining fixing device utilizing the connecting rod motion principle. The piston circumferential surface machining fixing device utilizing the connecting rod motion principle comprises a base, a main shaft is movably connected in the inner part of the base, a clamp is fixedly connected on the outer portion of the main shaft, a guide rod is fixedly connected in the inner part of the clamp, a threaded rod is slidably connected on the outer portion of the guide rod, a clamping rod is hinged tothe outer portion of the threaded rod, a limiting sliding block is hinged to the outer portion of the clamping rod, a clamping jaw is hinged to the outer portion of the clamping rod, and a threaded block is in threaded connection with the outer portion of the threaded rod. According to the piston circumferential surface machining fixing device utilizing the connecting rod motion principle, the effect of clamping a piston is achieved through cooperative use of the guide rod, the threaded rod, the clamping rod, the limiting sliding block and the clamping jaw, due to the fact that the clamping jaw is movably connected with the clamp, pistons of different models and sizes can be clamped, the application range of the device is enlarged, preparation of special clamping pieces is reduced, the trouble of replacing the clamp is avoided, the device cost is further reduced, and the piston machining efficiency is improved.

Owner:朱洁怡

Substrate glass light transmittance detection equipment and substrate glass preparation process

ActiveCN112763462AHigh control precisionReduce mistakesTransmissivity measurementsLiquid crystalEngineering

The invention relates to the technical field of liquid crystal panel production, and discloses substrate glass light transmittance detection equipment and a substrate glass preparation process. The substrate glass light transmittance detection equipment comprises an electric sliding rail, a differential mechanism, a hydraulic machine, a light emitter, a light receiver and an air compressor, a detection support is arranged above the electric sliding rail, and two telescopic lifting rods are arranged on the detection support in a lifting mode; hydraulic machines are arranged at the top ends of the telescopic lifting rods, detector mounting blocks are arranged at the bottom ends of the telescopic lifting rods, and a light emitter and a light receiver are arranged at the bottom ends of the two telescopic lifting rods correspondingly. The two telescopic lifting rods which are correspondingly arranged and can slide in the annular grooves are arranged, the two driving cross rods are driven by the driving shafts to synchronously rotate, the driving cross rods synchronously rotate and are transmitted to the two telescopic lifting rods through the connecting rings to enable the two telescopic lifting rods to synchronously rotate, and then the included angles between the two telescopic lifting rods and the glass substrate can be adjusted; and therefore, the light transmittance of different angles of each point in the same column position can be further detected.

Owner:茶陵晶辉电子实业有限公司

a firewood device

A firewood splitting device disclosed by the invention comprises a frame, a dovetail chute is fixedly connected to the frame, and a cutter assembly is slidably connected to the dovetail chute. In the firewood splitting device of the present invention, the distance between the cutter assembly is adjusted by the cutter adjustment device to ensure that the center of the cutter assembly is in line with the center of the wood; the wood can be placed between the limit bar and the horizontal ring, and the wood is guaranteed to be vertical Place it; knock the top of the wood with an external force to split the wood, and the split wood will slide down to the side ground along the slide to complete the wood chopping operation. The use of a slide plate can make the split wood slide down to the side ground along the slide plate, which is convenient for material collection. The firewood splitting device of the present invention has the advantages of simple structure, low cost and safe use.

Owner:XIAN AERONAUTICAL POLYTECHNIC INST

A self-centering yarn drum positioning device for twisting machine

The invention relates to the technical field of textile fabrics, and discloses an automatic centering yarn drum positioning device for a twisting machine, which includes a twisting machine body, and a fixed shaft sleeve is fixedly connected to the outside of the twisting machine body. The inside of the shaft sleeve is fixedly connected with a first bearing; The outside of the brake ring is connected with a brake ring, the outside of the brake ring is fixedly connected with a brake runner, the inside of the brake ring is fixedly connected with a bump, and the outside of the twisting machine body is fixedly connected with a fixed block, The outside of the fixed block is slidably connected with a brake slider. Through the cooperation of the rotating shaft and the positioning rod, the vertically fixed pay-off barrel becomes a horizontally fixed pay-off barrel, which avoids reducing the friction between the wire and the pay-off barrel, and avoids the occurrence of wire rods. damage, to ensure the quality of the wire.

Owner:南通鑫唐纺织印染有限公司

Automatic flaring machine

ActiveCN105499416BGuaranteed collinearImprove positioning accuracyMetal-working feeding devicesPositioning devicesClamp connectionEngineering

Owner:GREE ELECTRIC APPLIANCES INC

Wood plate fillet polishing device for furniture production

InactiveCN113523954AConducive to mutual fixationReduce labor costsEdge grinding machinesGrinding drivesLap jointEngineering

The invention relates to the technical field of furniture production equipment, in particular to a wood plate fillet polishing device for furniture production. The wood plate fillet polishing device comprises a mounting plate, a pair of lap joint plates, a clamping device, a centering device, a swinging device, a feeding device and a polishing device body, and handles are mounted on two sides of the mounting plate; the lap joint plates are symmetrically arranged at the front end of the mounting plate relative to the mounting plate; the clamping device is mounted on the vertical lap joint part of the lap joint plate and is positioned below the horizontal lap joint part; the centering device is mounted on the mounting plate, and the working direction of the centering device is located on the angular bisector of the pair of lap joint plates; the swinging device is mounted at the working end of the centering device, and the swinging device is bilaterally symmetrical about the working direction of the centering device; the feeding device is installed at the working end of the swinging device, and the working direction of the feeding device is arranged in the radial direction of the swinging device; and the polishing device body is mounted at the working end of the feeding device; According to the scheme, labor cost can be effectively reduced, working efficiency is improved, and the working effect is stable.

Owner:张青丰

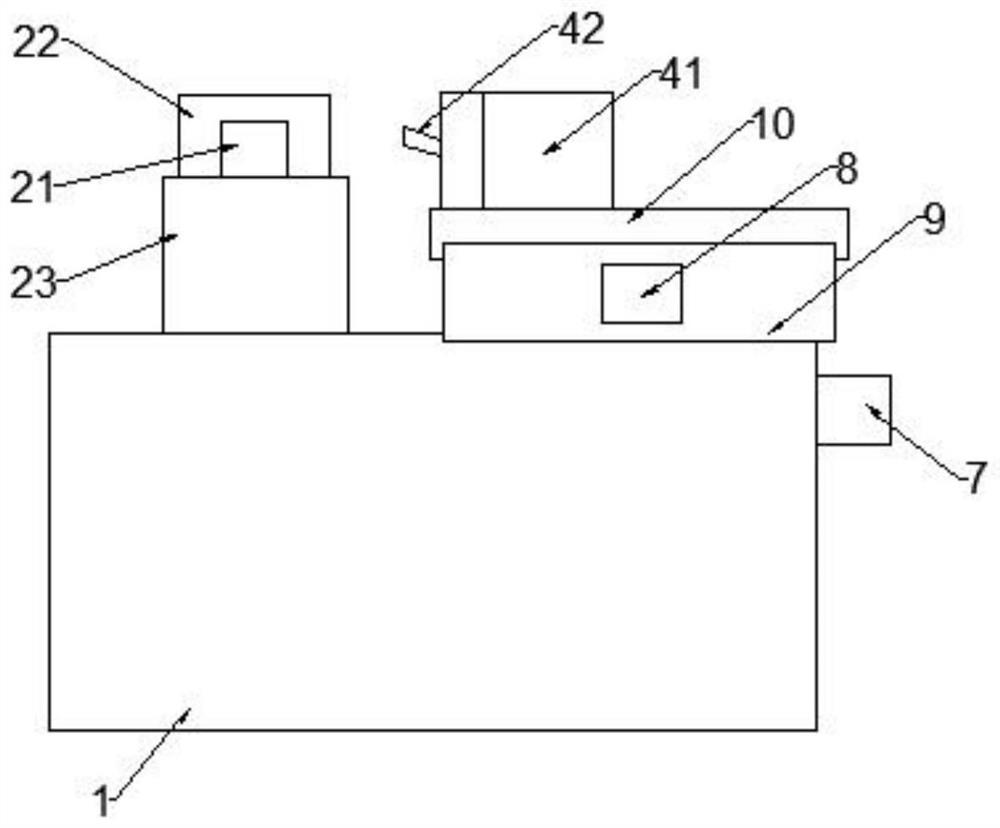

Screw machining device

PendingCN113172439AQuick fixGuaranteed collinearFeeding apparatusPositioning apparatusMachiningPhysics

The invention discloses a screw machining device. The screw machining device comprises a lathe bed, wherein a first clamping device, a second clamping device and a cutting device capable of moving on the lathe bed in an X-axis direction and a Y-axis direction are arranged on the lathe bed, and the screw machining device further comprises an auxiliary device which is used for guaranteeing that after a blank is fixedly supported by the auxiliary device and thus clamped by the first clamping device and the second clamping device, the first clamping device, the second clamping device and the axis of the blank are located on the same horizontal plane, the auxiliary device comprises two clamping plates, a hinge, a locking piece and a supporting part, contact faces of the two clamping plates and the blank are semicircular, one clamping plate is connected with the supporting part, the two clamping plates are connected through the hinge, and the locking piece is used for locking the two closed clamping plates. According to the screw machining device, through cooperation of the two clamping plates and the locking piece, the blank can be rapidly fixed, the blank cannot be tilted when clamped by chunks, it is guaranteed that the axis of the blank and the axes of the chucks are collinear, and then it is guaranteed that a machined screw can match star wheels in use.

Owner:江西奥夫科压缩机有限公司

A Self-excited Oscillating Pulse Swirl Supercharger

The invention provides a self-oscillation type pulse cyclone supercharger. The self-oscillation type pulse cyclone supercharger comprises a shell, an air inlet adjusting pipe, a left end cover, a pulse cyclone blade, an air outlet adjusting pipe and a right end cover; a main air inlet and a main air outlet are formed in the left end and the right end of the shell correspondingly; the left end cover and the right end cover of the shell are fixed through an M8 screw; the pulse cyclone blade is arranged inside the shell; the air inlet adjusting pipe is installed at the left end of the pulse cyclone blade; the air outlet adjusting pipe is installed at the right end of the pulse cyclone blade; two supporting leg bases are welded to the shell; the pulse cyclone blade comprises a center sleeve pipe and a cyclone blade arranged at the concave portion of the center sleeve pipe; particles and gas in the center sleeve pipe flow in the axial direction; a pulse cyclone air flow is formed between the shell and the pulse cyclone blade; and an auxiliary supplementing air inlet is formed in the shell and is in G1 pipe threaded connection. The self-oscillation type pulse cyclone supercharger is wide in application range, can reduce the minimum conveying speed of the particles, relieve the pipe abrasion, reduce particle crushing and avoid pipe blockage, and is suitable for pneumatic long-distance conveying of material particles.

Owner:CHINA UNIV OF MINING & TECH

Wire and cable winding device

The invention relates to the technical field of electric wires and cables, in particular to an electric wire and cable winding device. The device comprises a driving structure and a supporting and fixing structure, wherein the driving structure comprises a drive roller; the supporting and fixing structure further comprises a rotating frame, a connecting block, a supporting rod, a rolling wheel and a fixing rod; the drive roller is rotationally contained in the rotating frame; a first through hole is formed in the rotating frame; one end of the connecting block is fixedly connected with the outer circumferential face of the drive roller; the connecting block penetrates through the first through hole; one end of the fixing rod is fixedly connected with the outer circumferential face of the rotating frame; and the other end of the fixing rod is in pivot connection with the rolling wheel. The rotating frame sliding relative to the drive roller is arranged on the drive roller, so that the supporting rod rapidly rotates around the connecting block, the end, away from the connecting block, of the supporting rod rapidly abuts against the inner circumferential face of a winding roller, and stable fixing of the winding roller is achieved; and the device can adapt to the winding operation of the winding rollers with different calibers on electric wires and cables, is wide in application range, and can drive the winding rollers to rotate stably.

Owner:宋凯

A drug dissolution tester

ActiveCN106442904BGuaranteed credibilityIncrease support distanceTesting medicinal preparationsWater bathsElectric machinery

The invention discloses a test instrument for dissolution rate of drugs and mainly relates to the technical field of drug inspection. The test instrument comprises a base, wherein four adjusting bolts are arranged at the edge of the base; a reference block is arranged on the base; a level bubble is arranged on the reference block; a cylindrical lug boss and a heating box are arranged at the top of the base; an annular water bath box is arranged on the cylindrical lug boss in a sleeving manner; an annular cover is arranged at the top of the annular water bath box; a lifting mechanism is arranged on the cylindrical lug boss; a cylindrical shell is arranged at the top of the lifting mechanism; a driving motor is arranged at the top of the cylindrical shell; a plurality of rotating shafts are annularly arrayed on the cylindrical shell; stirring paddles are arranged at the bottom of the rotating shafts; a dissolving cup is arranged in the annular water bath box. The test instrument has the beneficial effects of reducing the interference factor of the dissolution rate test, guaranteeing the reliability of the test result, shortening the time for correcting the test instrument for dissolution rate and improving the working efficiency.

Owner:上海安德盛实业有限公司

A fast filament feeding device for fdm type 3d printing filament

ActiveCN111113897BMeet diameter requirementsImprove universalityAdditive manufacturing apparatus3D object support structuresWire rodSpray nozzle

Owner:合肥名龙电子科技有限公司

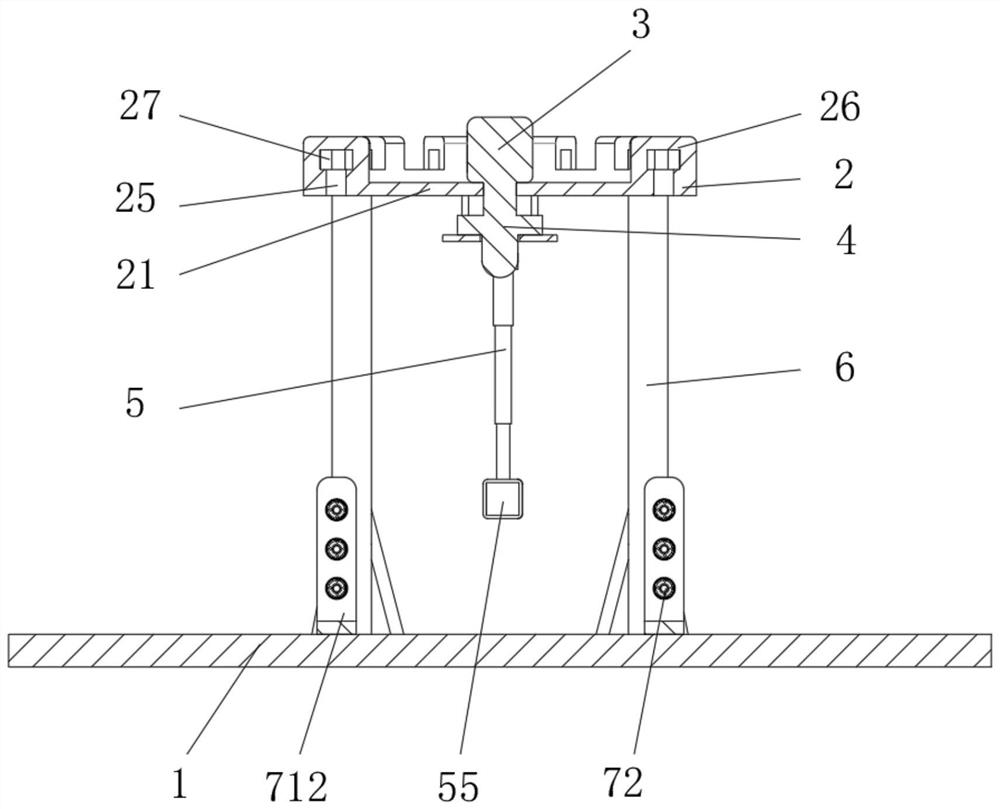

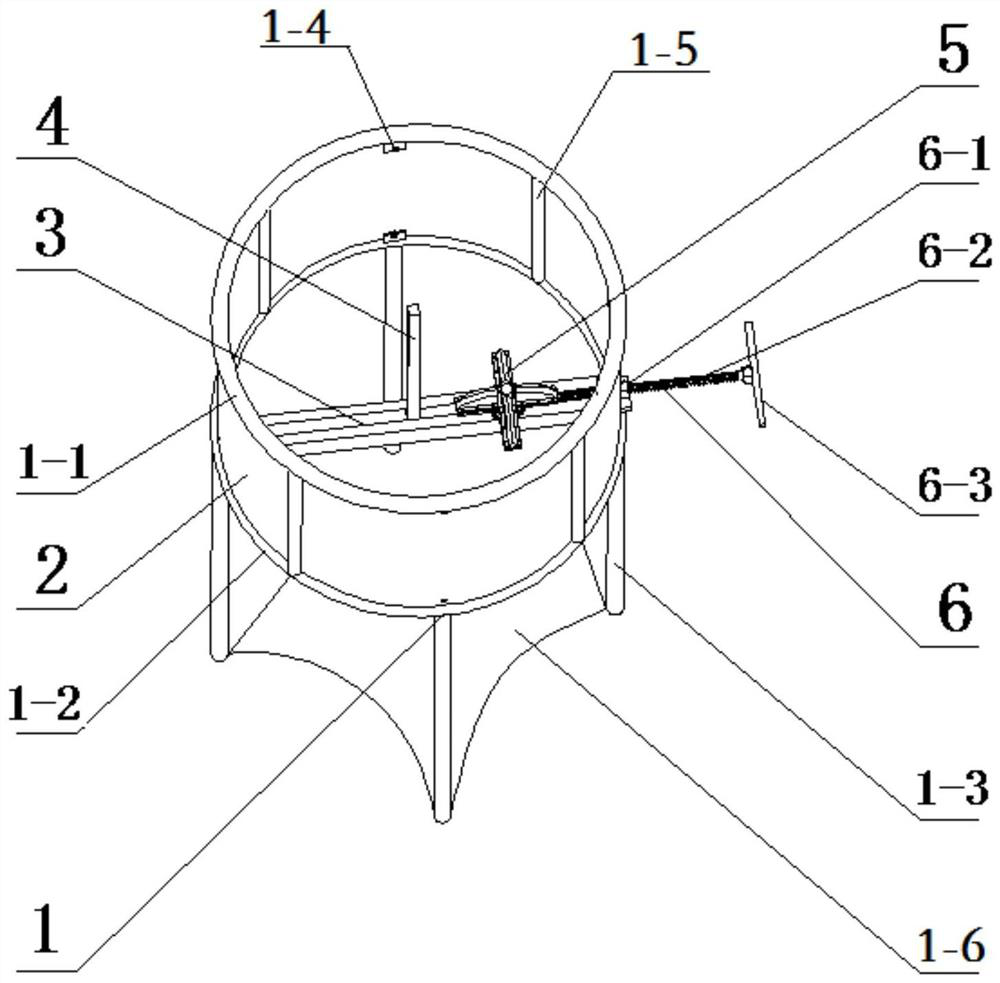

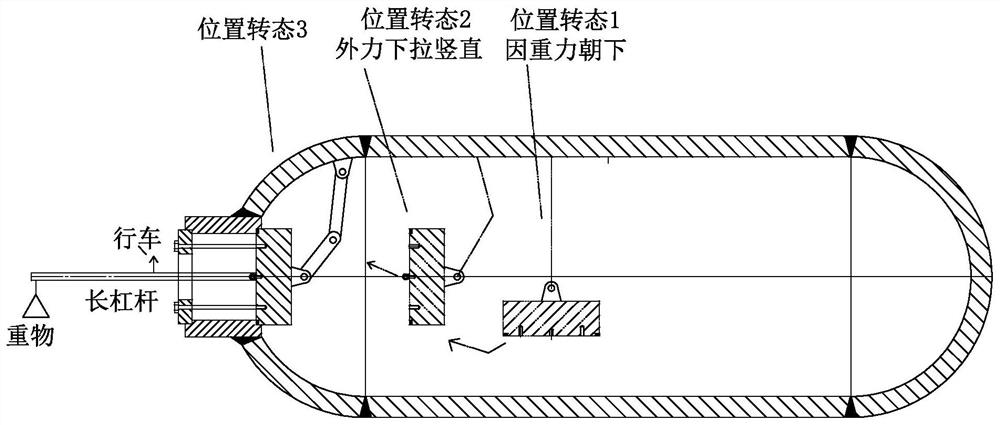

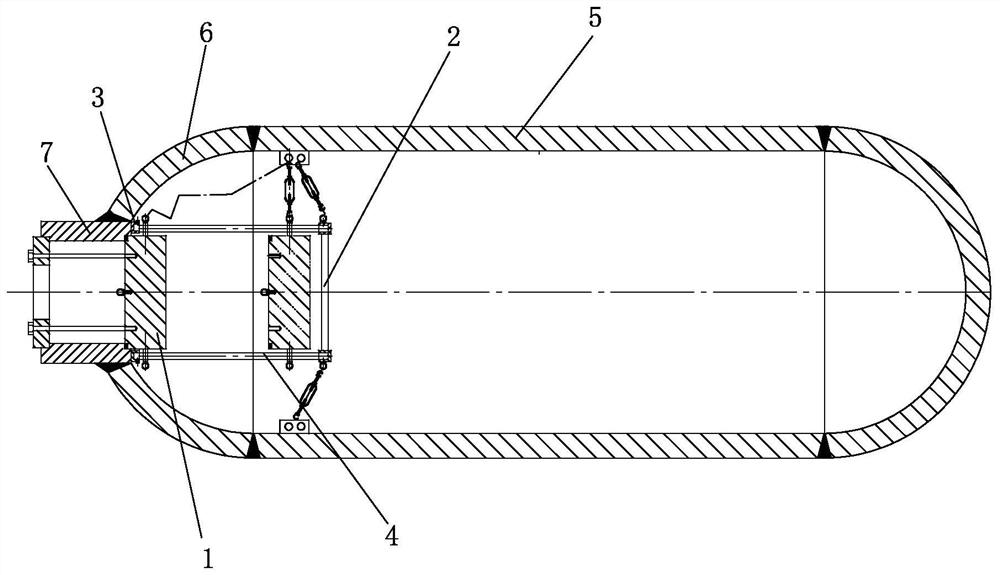

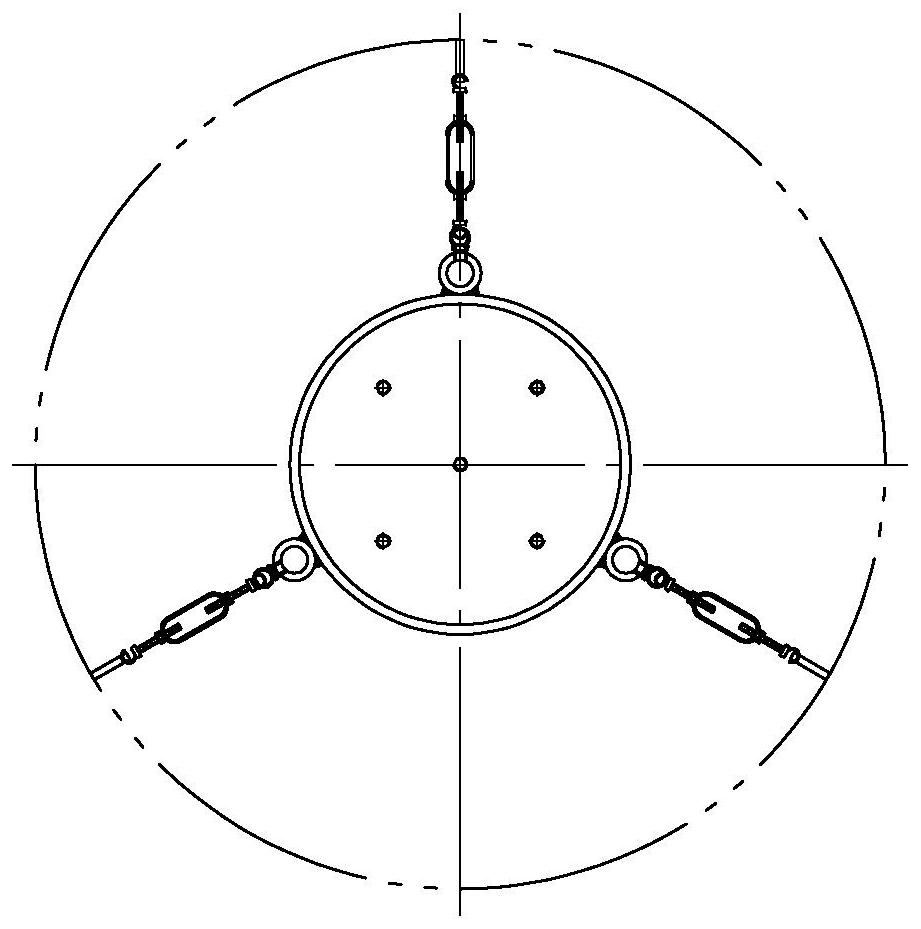

Combined manhole tooling and internal pressure manhole installation method

ActiveCN111546284BPlay a guiding roleImprove installation efficiencyMetal-working hand toolsPilot holeIndustrial engineering

The invention discloses a combined manhole tooling, which is used for installing a manhole cover with at least three guide sleeves distributed at equal intervals in a ring on the outer peripheral surface, including a positioning cylinder, a pallet frame, a positioning seat and a guide rod; the positioning seat is used for Positioned by the positioning cylinder and installed on the edge of the manhole; the guide rod is used to penetrate into the guide hole of the guide sleeve and provide support for the manhole cover, so that the manhole cover can slide along the guide rod; the two ends of the guide rod can pass through the positioning respectively The seat and the support base on the bracket plate are supported and positioned. A method for installing an internal pressure manhole, using the combined manual tooling of the present invention to install the manhole cover on the edge of the manhole. The invention gets rid of the dependence on the long lever and the driving, and a single person can complete the assembly of the combined manhole tooling and the installation of the manhole cover, with high installation efficiency and low installation cost.

Owner:重庆水泵厂有限责任公司

A kind of transmission device of multi-clutch transmission

ActiveCN104074931BWide range of speed ratioSimple internal structureGearboxesToothed gearingsClutchElectrical and Electronics engineering

The invention provides a multi-clutch transmission drive unit. The multi-clutch transmission drive unit comprises a first double-clutch transmission and a second double-clutch transmission, wherein the output shaft of the first double-clutch transmission is connected with the shell of the second double-clutch transmission. According to the multi-clutch transmission drive unit provided by the invention, a multi-stage clutch structure in one transmission is replaced by the two double-clutch transmissions, and the multi-clutch transmission drive unit is simple in structure and high in reliability while realizing speed ratio range expansion.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

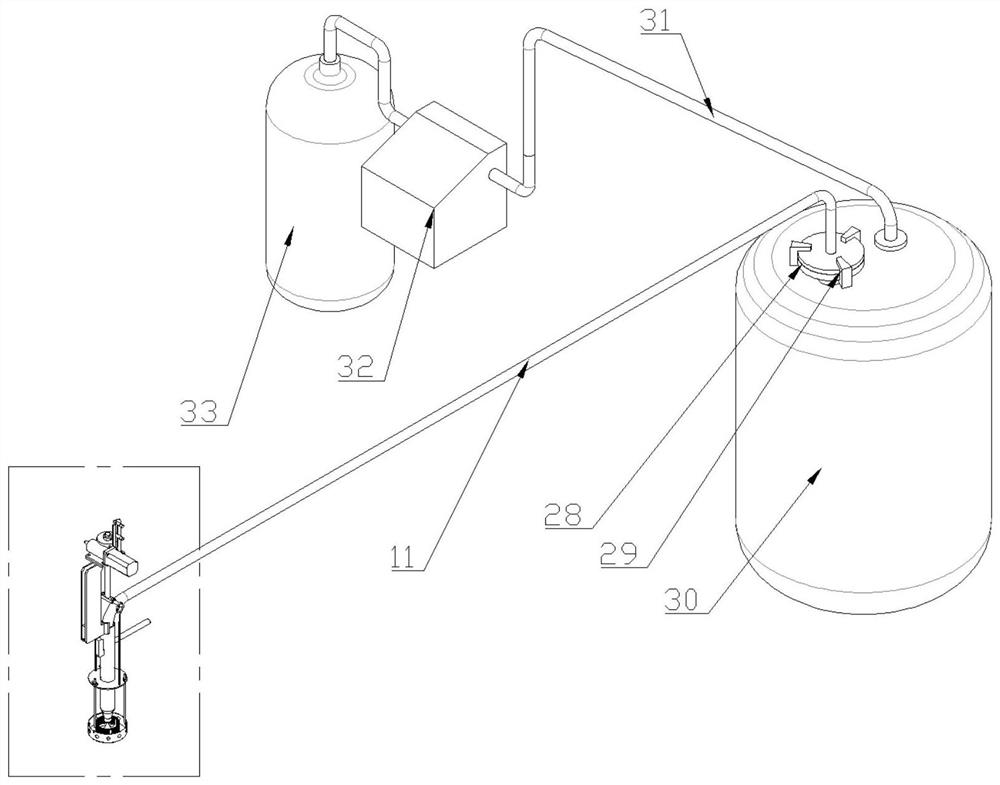

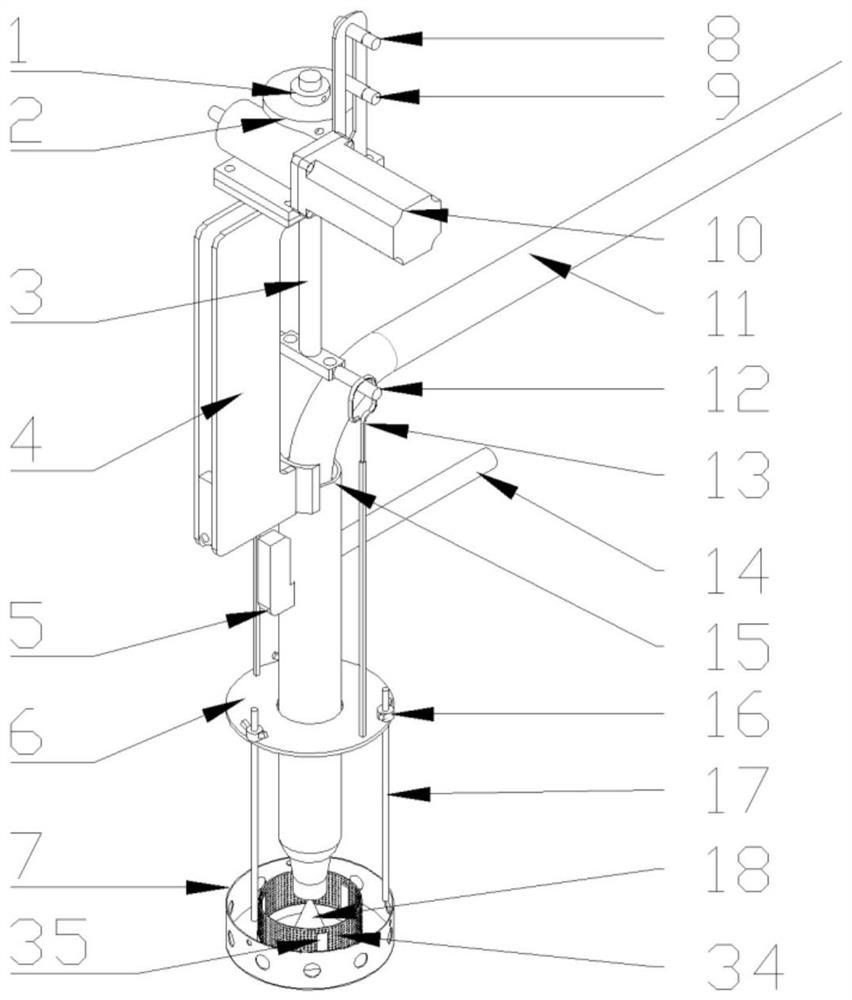

Liquid guiding device and method for stabilizing and controlling flow in magnesium alloy semi-continuous casting process

Owner:NORTHEASTERN UNIV LIAONING

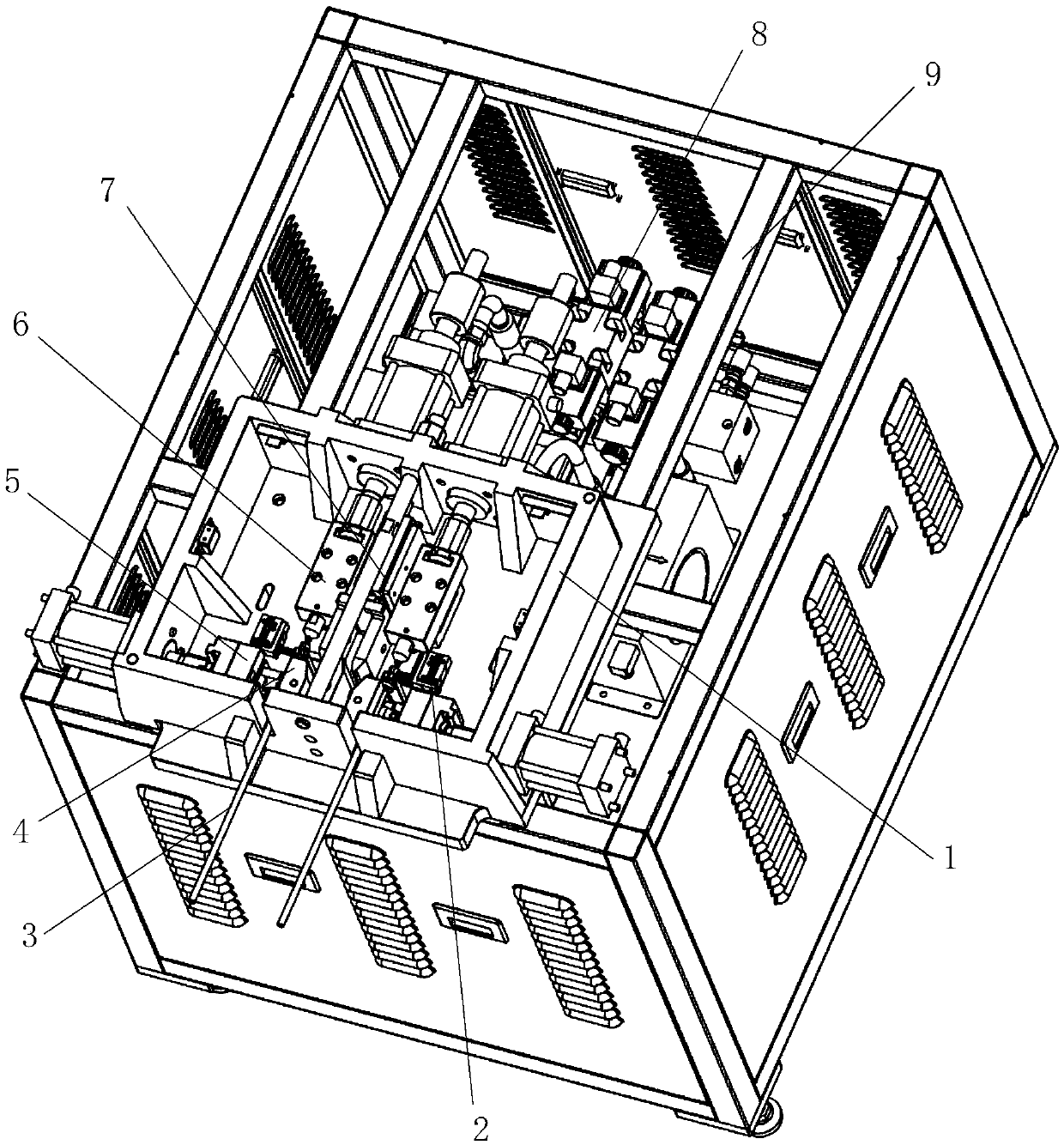

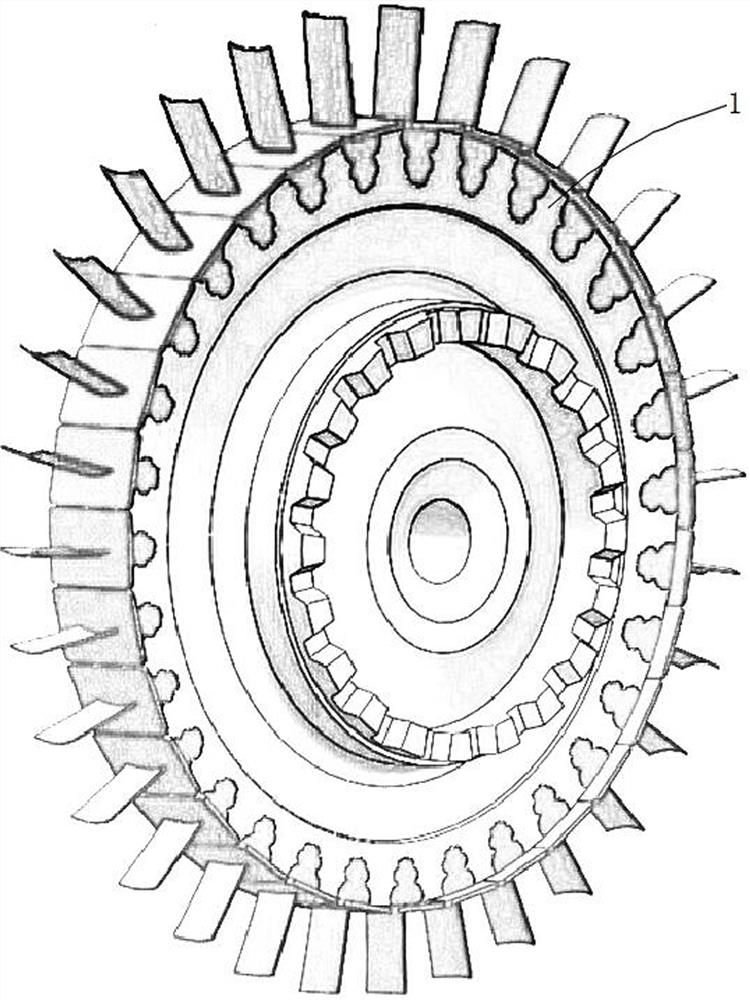

Device used for precisely grinding turbine disc blade assembly

PendingCN113146471AIncrease the workable areaGuaranteed accuracyGrinding machinesGrinding work supportsPhysicsTurbine blade

The invention discloses a device used for precisely grinding a turbine disc blade assembly. The turbine disc blade assembly comprises a turbine disc in the middle, turbine blades are uniformly distributed on the outer edge of the turbine disc, and gear discs are arranged on the two sides of the turbine disc. The device comprises a positioning assembly for pressing and positioning the turbine disc blade assembly, the positioning assembly comprises a first end tooth clamping piece, a second end tooth clamping piece and a center piece, and the first end tooth clamping piece and the second end tooth clamping piece are highly engaged with the gear discs on the two sides of the turbine disc correspondingly. One end of the center piece is fixedly connected with the first end tooth clamping piece through a screw, and the other end of the center piece is fixedly connected with the second end tooth clamping piece through a tensioning screw. The end tooth faces of the turbine disc blade assembly are connected in cooperation, the end tooth faces of the two parts are formed through precision machining, a good engagement degree is achieved, it can be guaranteed that axis collineation in the process of precisely grinding the turbine disc blade assembly can be guaranteed, and it is guaranteed that the grinding process of the turbine blades is more precise.

Owner:SICHUAN YAMEI POWER TECH

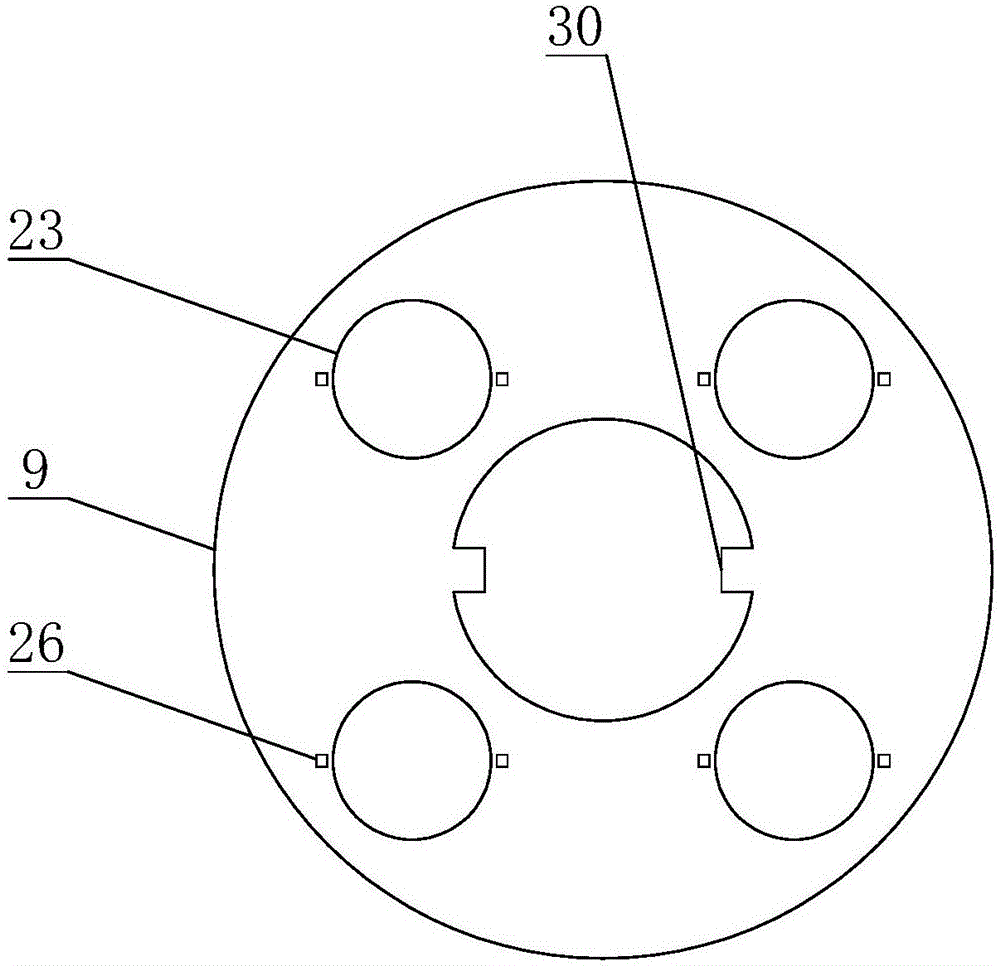

Method and device for measuring vertical divergence angle of high-power laser diode array

InactiveCN102539116BGuaranteed to workGuaranteed collinearSpectrum investigationTesting optical propertiesMeasurement deviceHigh power lasers

The invention discloses a device and a method for measuring the vertical divergence angle of a high-power laser diode array. The method comprises the following steps: calibrating the device for measuring the vertical divergence angle of the high-power laser diode array; and measuring the spectrum intensity vertical to the light-emitting surface of the laser diode array, carrying out difference operation through different revolving angles of a revolving plate under the same spectrum intensity, and further acquiring the vertical divergence angle of the high-power laser diode array. The device and the method for measuring the vertical divergence angle of the high-power laser diode array provided by the invention have the advantages that the measuring device has a collimation system, the vertical divergence angle and the spectrum characteristic of the laser diode array can be measured accurately; and additionally, a water cooling system is introduced according to the invention, the operation of the laser diode at the normal temperature is ensured.

Owner:BEIJING GK LASER TECH

Gluing device for medical needles

ActiveCN104437983BPrevent tiltingEvenly distributedLiquid surface applicatorsCoatingsMedical equipmentApparatus instruments

The invention provides a glue coating device for medical needles, which belongs to the technical field of medical equipment manufacturing equipment. It solves the technical problems such as uneven glue application of the existing medical needle glue application device. The gluing device for medical needles includes a frame, a lifting plate connected with the frame and a rubber plate for gluing, the lifting plate is connected with a relatively set mounting plate 1 and mounting plate 2, mounting plate 1 and mounting plate 2. Through the relative or opposite movement of the driving source 2, the first mounting plate and the second mounting plate are respectively equipped with a needle rubbing plate, and the needle rubbing plate is respectively positioned by the driving source 3 fixed on the mounting plate 1 and the mounting plate 2. The opposite sides of the two rubbing plates on plate 1 and mounting plate 2 are clamping surfaces, and the clamping surfaces of the two rubbing plates can abut against each other and clamp the needle tube when mounting plate 1 and mounting plate 2 move relatively. The driving source three can drive the corresponding rubbing board to move along its length direction and the two rubbing boards move relatively. The invention has the advantage of being able to apply glue stably and evenly.

Owner:MAIDER MEDICAL IND EQUIP

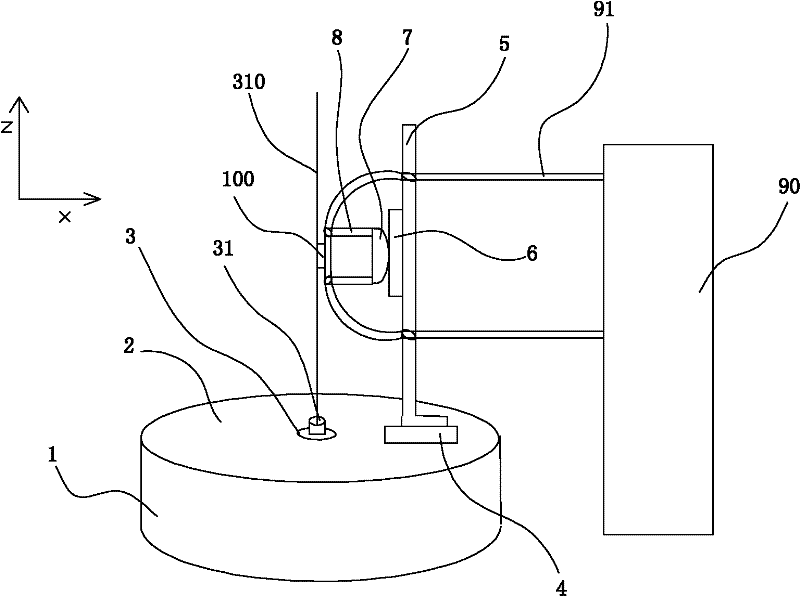

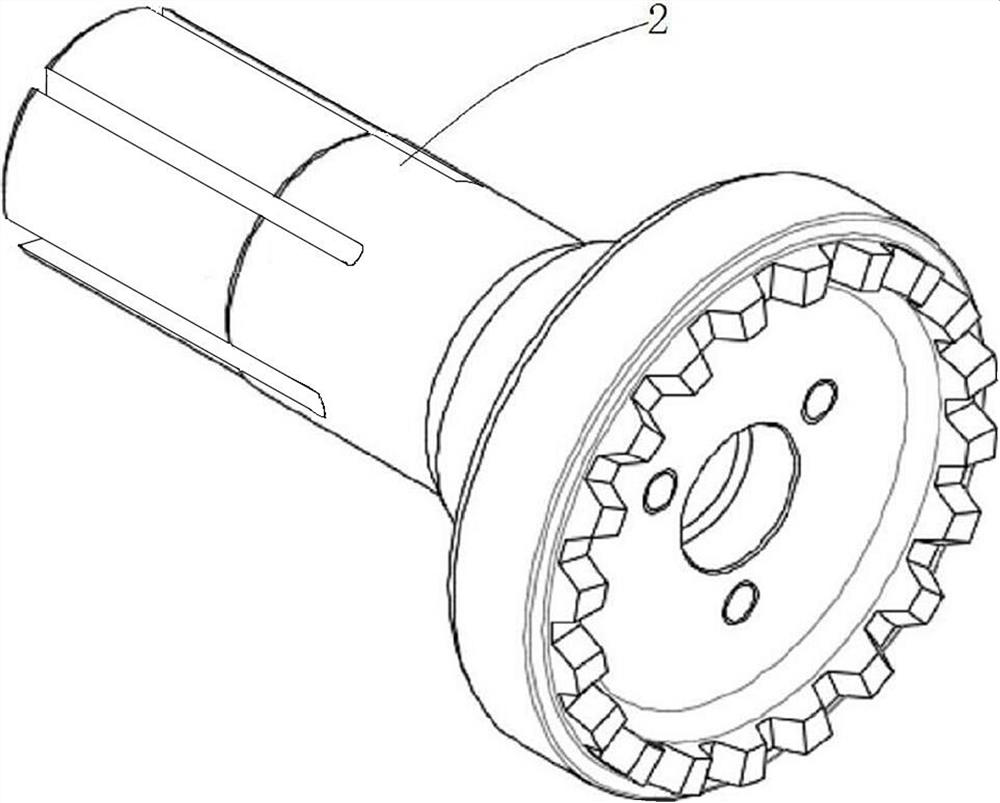

Device for measuring vertical divergence angle of high-power laser diode array

InactiveCN102539125BWork lessGuaranteed collinearOptical apparatus testingHigh power lasersDivergence angle

The invention discloses a device for measuring the vertical divergence angle of a high-power laser diode array. The device comprises a base plate, a rotary plate, a central shaft, a first displacement regulator, an L-shaped support, a second displacement regulator, a unidirectional pitching regulator, a laser diode array support tool and a water cooling system, wherein angle coordinates are engraved on the base plate; the rotary plate is arranged on the base plate in a rotatable mode and is provided with calibration tails; the central shaft is arranged on the center of the base plate and penetrates through the rotary plate; the first displacement regulator is installed on the rotary plate and is positioned beside the central shaft; the L-shaped support is fixed on the first displacement regulator; the second displacement regulator is installed on the L-shaped support; the unidirectional pitching regulator is installed on the second displacement regulator and can pitch along the vertical direction; the laser diode array support tool is installed on the unidirectional pitching regulator; and the water cooling system is connected with the laser diode array support tool. The device for measuring the vertical divergence angle of the high-power laser diode array provided by the invention has the advantages that the operation of the high-power laser diode array at normal temperature is ensured, the center collineation of a light-emitting line and the central shaft is also ensured, and the measuring accuracy is improved as well as the aim that the laser diode array with different heat sink widths can be measured is realized.

Owner:BEIJING GK LASER TECH +1

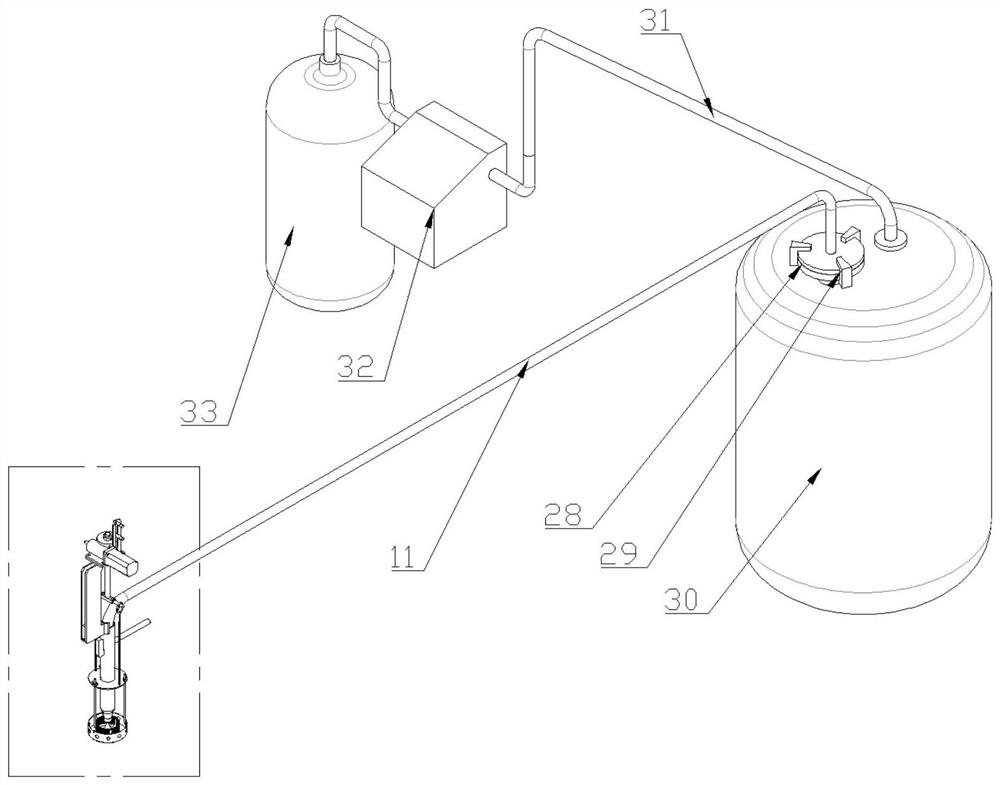

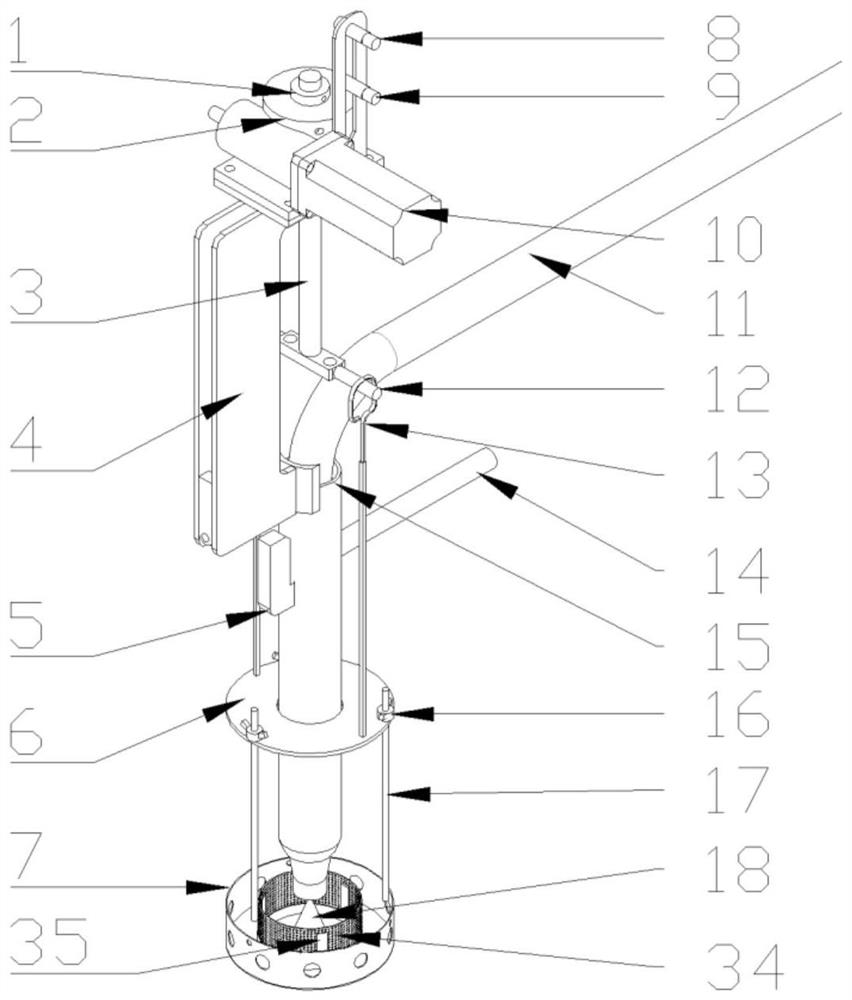

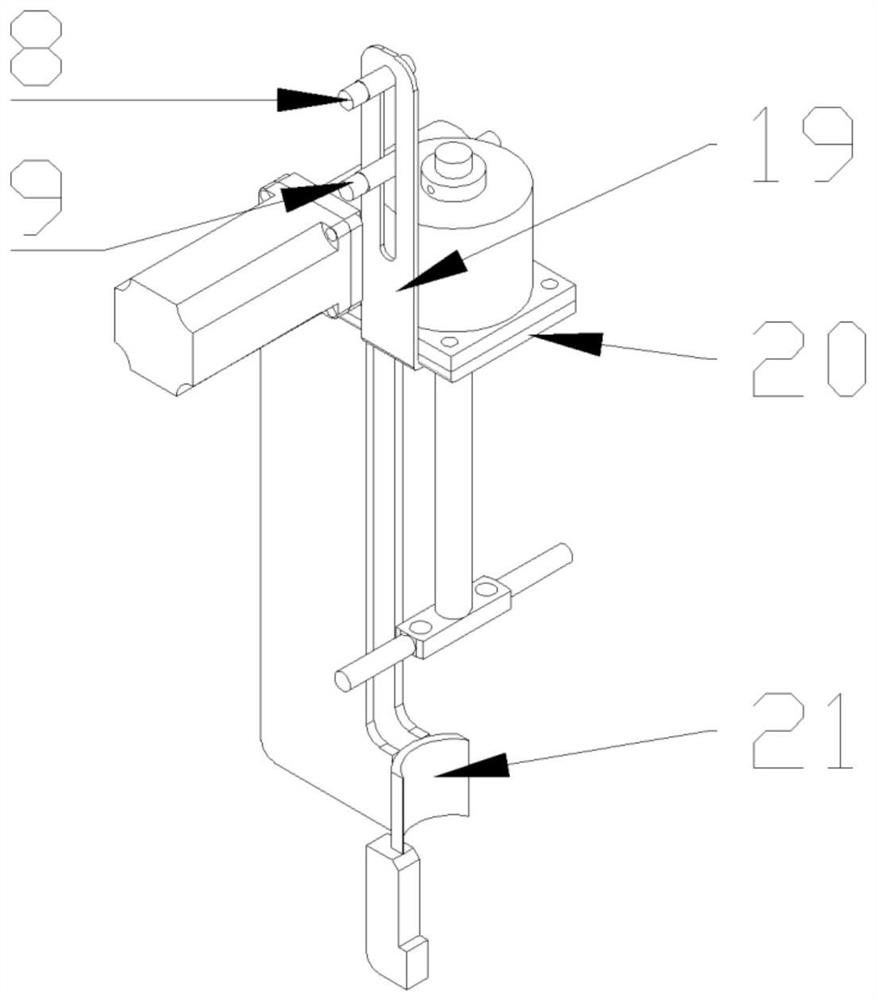

Liquid guide device and method for stable flow control in semi-continuous casting process of magnesium alloy

The invention discloses a Liquid guide device and method for stable flow control in the semi-continuous casting process of magnesium alloy, and belongs to the field of casting. The liquid guide device for stable flow control in the semi-continuous casting process of the magnesium alloy is provided with a liquid guide control actuator and a shielding gas control device; the liquid guide control actuator comprises a lifting device and a flow-dividing control device, the lifting device is connected to the flow-dividing control device, the lifting device is used for adjusting the flow-dividing control device to ascend and descend, and the flow-dividing control device is used for controlling the flow of magnesium alloy melt at the liquid outlet end of the liquid guide pipe; a crucible containing the magnesium alloy is connected to a shielding gas storage tank through a shielding gas conveying pipe, and a shielding gas control device is arranged on the shielding gas conveying pipe and used for controlling the pressure in the crucible by adjusting the shielding gas output process. According to the device, high-temperature melt can be stably conveyed in the semi-continuous casting process, the stability of the liquid level in a crystallizer is guaranteed, the surface quality and smoothness of products are improved, the possibility of slag inclusion is reduced, stable and safe casting production is achieved, and the applicability is wide.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com