Gluing device for medical needles

A gluing device and needle plate technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems of uneven gluing, affecting the quality of injection needles, needle tube tilting, etc., and achieve the effect of uniform gluing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

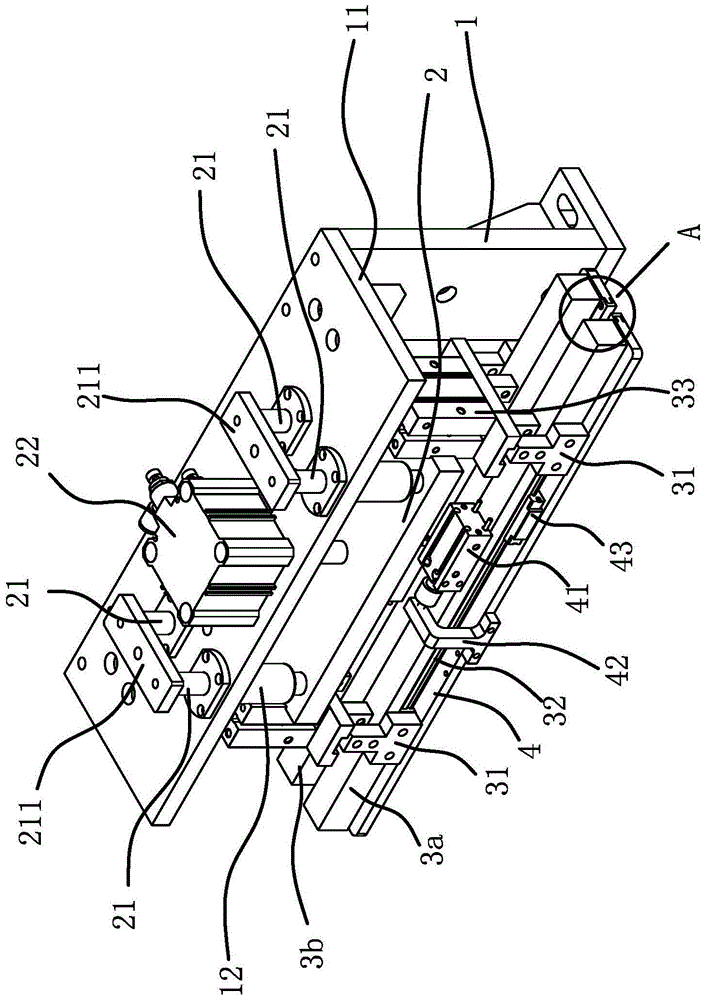

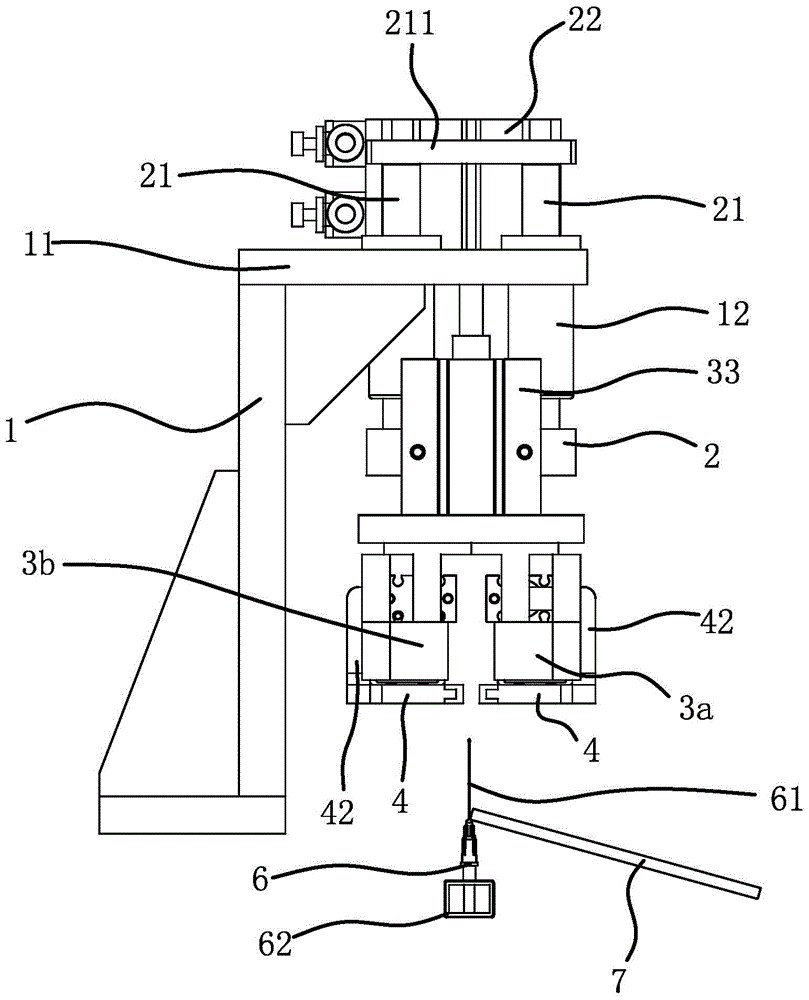

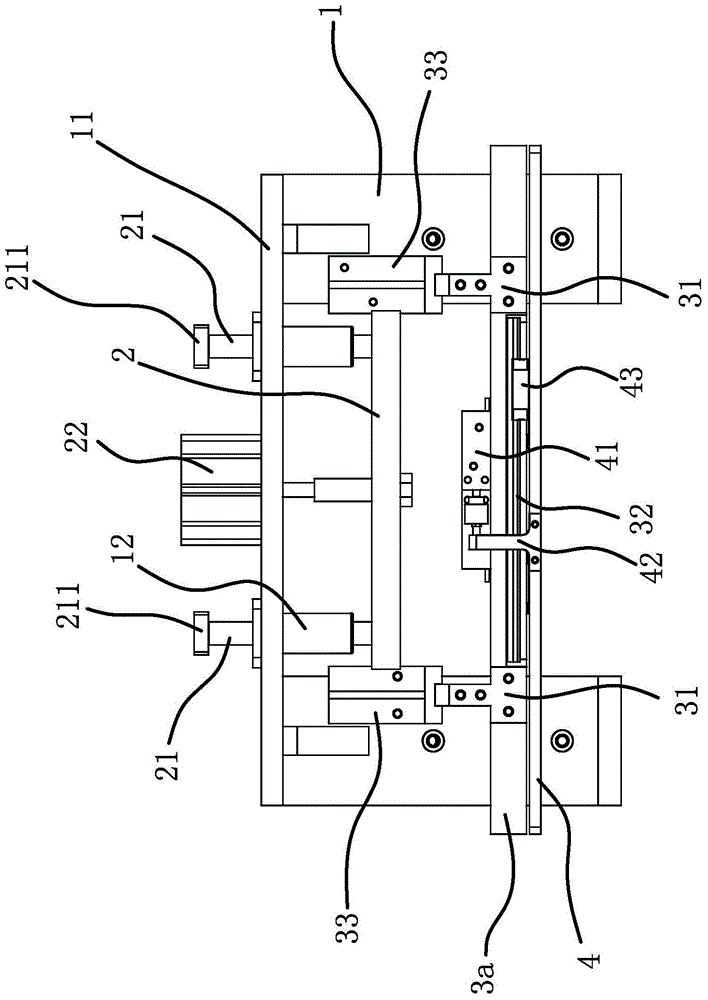

[0026] A glue coating device for medical needles, such as Figure 1 to Figure 5 As shown, it includes a frame 1, a lifting plate 2 and a rubber disc 7 for gluing. The frame 1 has a mounting table 11, and the mounting table 11 is provided with a clamping seat 62 for clamping the medical needle holder 6, and the needle tube 61 faces the mounting table 11 and is located between the rubbing plates 4 . The medical needles assembled by this gluing device are as follows: Figure 6 shown.

[0027] Such as Figure 1 to Figure 3 As shown, lifting plate 2 is located at the below of mounting platform 11, and driving source-22 is fixed on mounting platform 11, and driving source-22 can be cylinder, also can be motor, and driving source-22 cylinder in the present embodiment, the cylinder The cylinder body is fixed on the installation platform 11, and the telescopic rod of the cylinder is connected and fixed with the middle part of the lifting plate 2. The cylinder can drive the lifting p...

Embodiment 2

[0034] The structure and principle of this embodiment are basically the same as that of the first embodiment, except that the second driving source is a motor, the first mounting plate and the second mounting plate are vertically fixed with vertical plates, and screw rods are arranged between the vertical plates. The screw rod has opposite threads at two ends, and the two vertical plates are threadedly connected with the two ends of the screw rod respectively, the motor is fixed on the lifting plate, and the rotating shaft of the motor is fixed with the screw rod through a shaft coupling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com