Pouring frame fixing template structure for civil engineering construction

A technology for engineering construction and fixation of formwork, which is applied to building components, building structures, and on-site preparation of building components. , the use of stable, improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

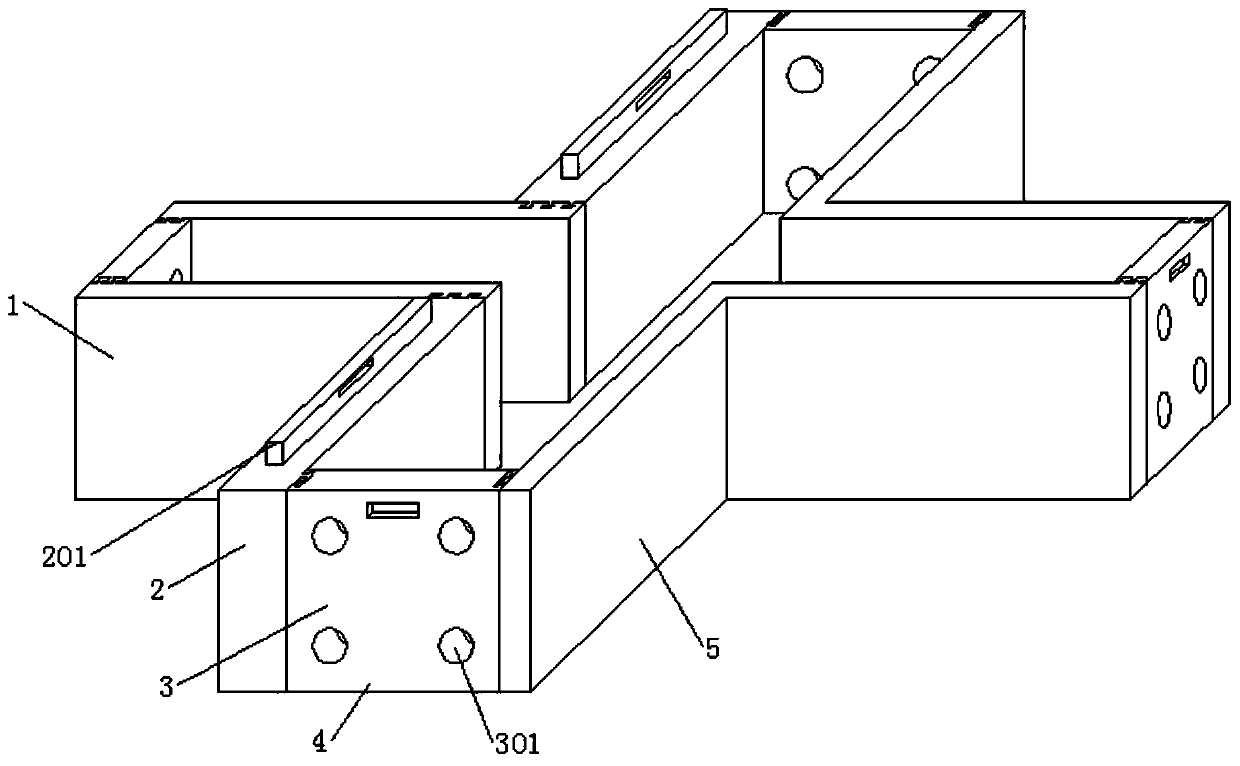

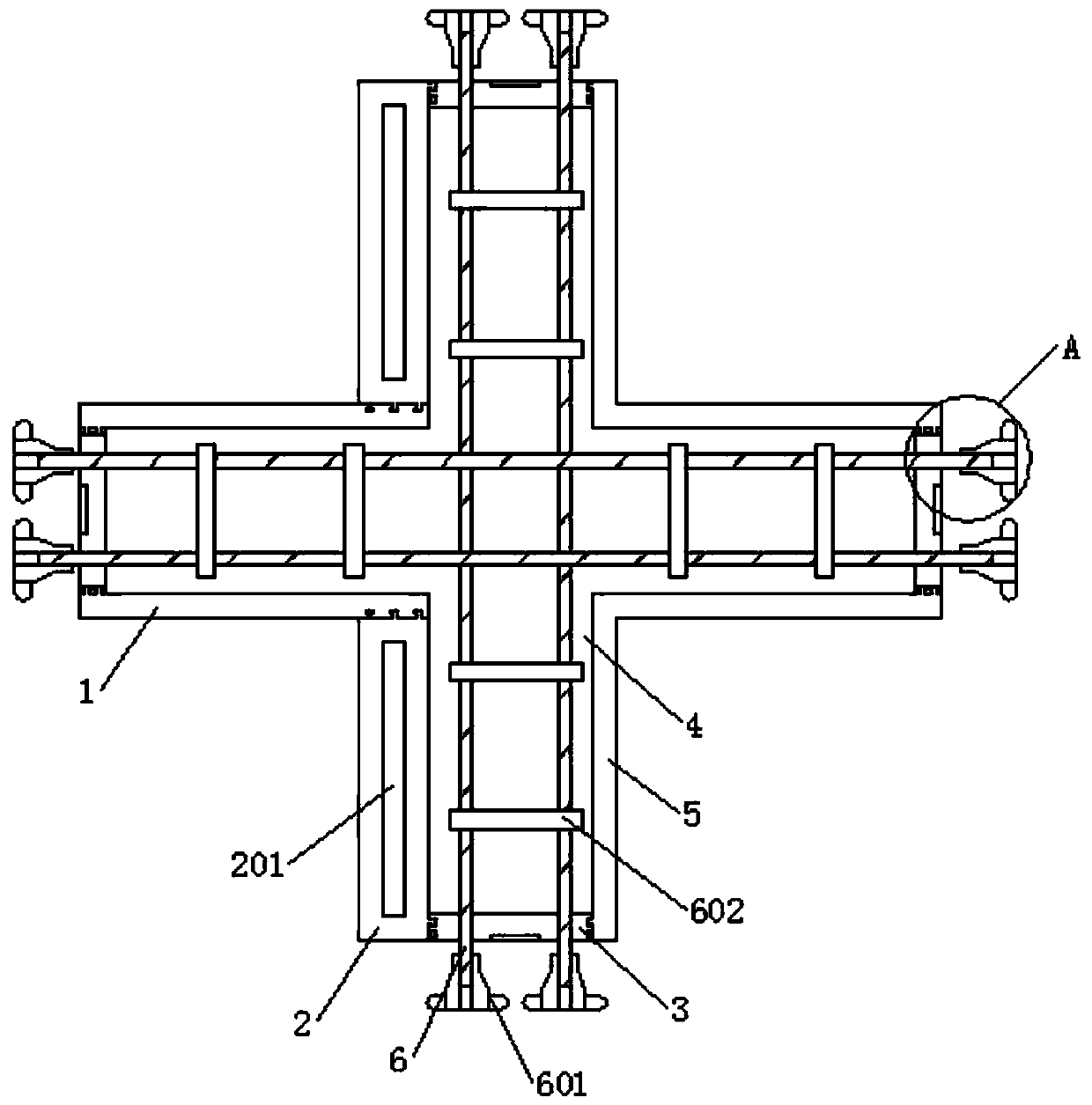

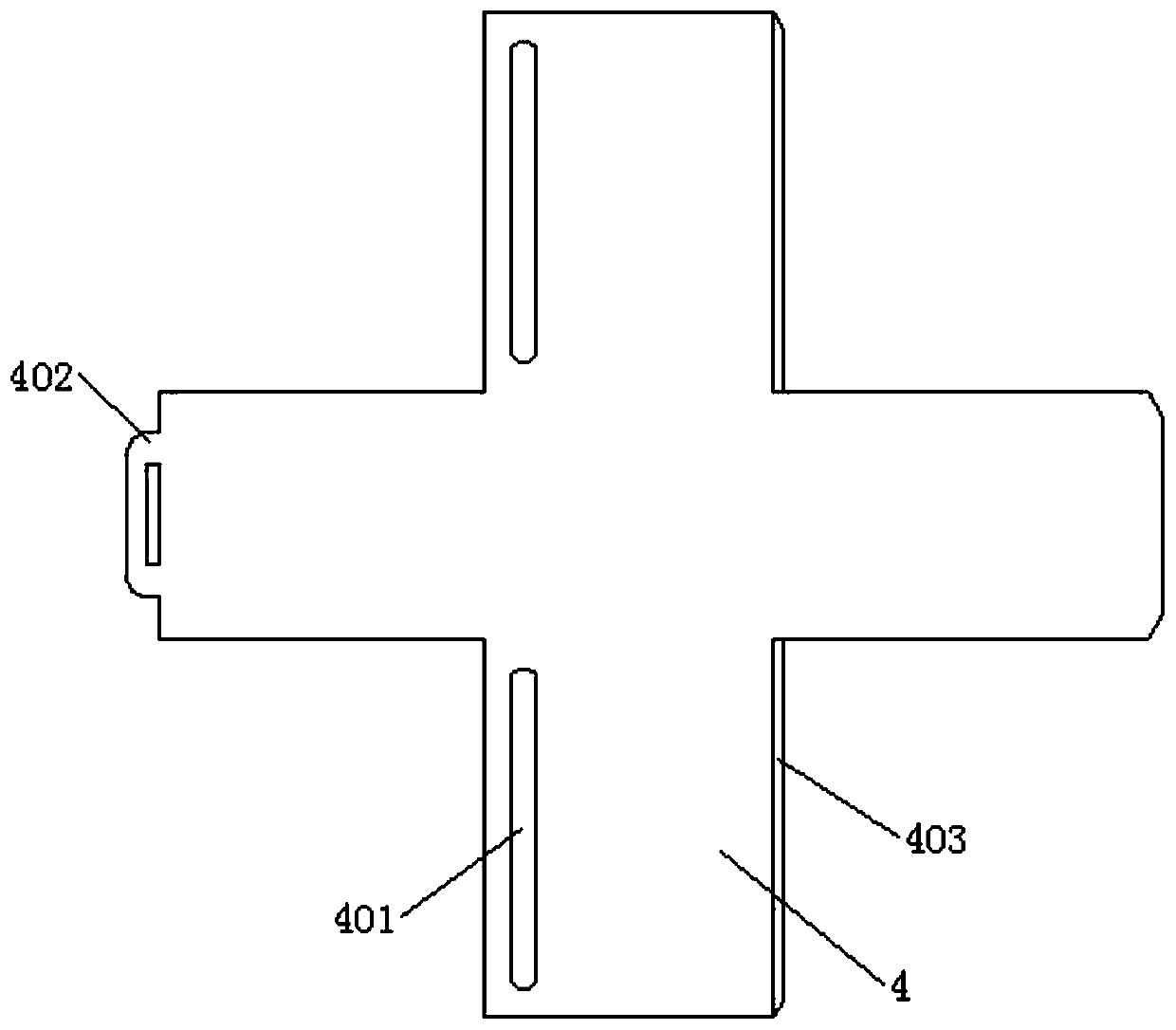

[0033] see figure 1 To attach Figure 9 , a pouring frame fixed formwork structure for civil engineering construction, including: single-sided baffle 1, card baffle 2, outer baffle 3, bottom plate 4, L-shaped baffle 5 and steel bar 6, single-sided baffle 1 The outer wall on the right side is provided with a card baffle 2, the outer wall on the right side of the card baffle 2 is provided with an outer baffle 3, the right side of the outer baffle 3 is provided with an L-shaped baffle 5, and the bottom of the L-shaped baffle 5 is provided with a bottom plate 4, A steel bar 6 is arranged on the top of the bottom plate 4 .

[0034] see figure 1 , figure 2 and Figure 4 , further, the card baffle 2 is arranged in a square shape, and the number of the card baffle 2 is 2 pieces, and the card baffle 2 fits with the singl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com