Device used for precisely grinding turbine disc blade assembly

A technology for precision grinding and turbine blades, which is applied in the direction of grinding workpiece supports, grinding/polishing equipment, grinding machines, etc., and can solve problems such as non-vertical, uneven surface, and inability to guarantee the shape and position tolerance of the outer circular surface of turbine blades. , to achieve precise grinding, save manufacturing costs, and improve high-precision grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

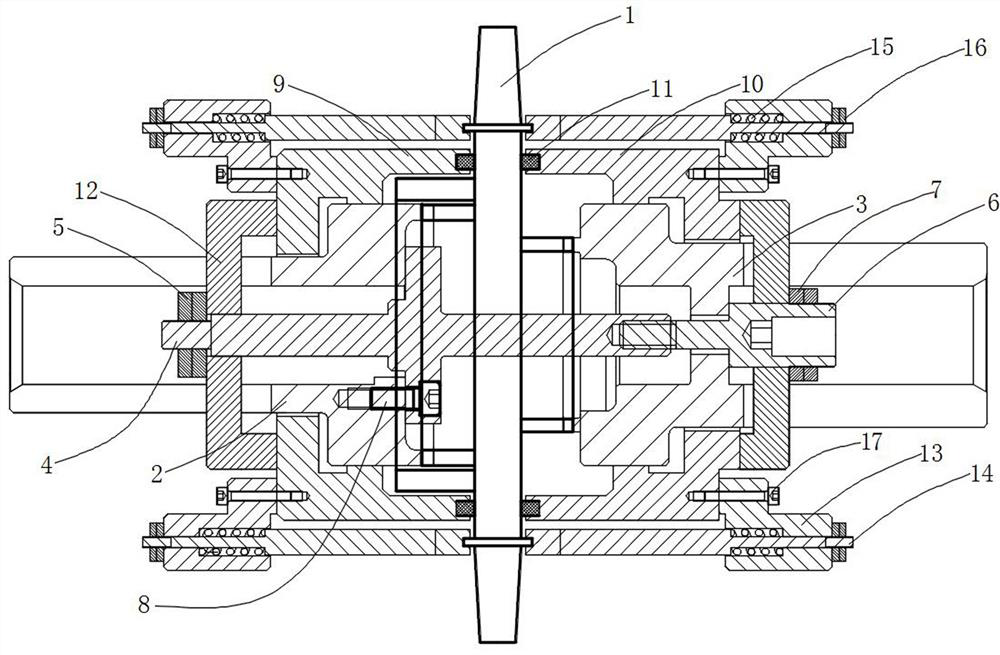

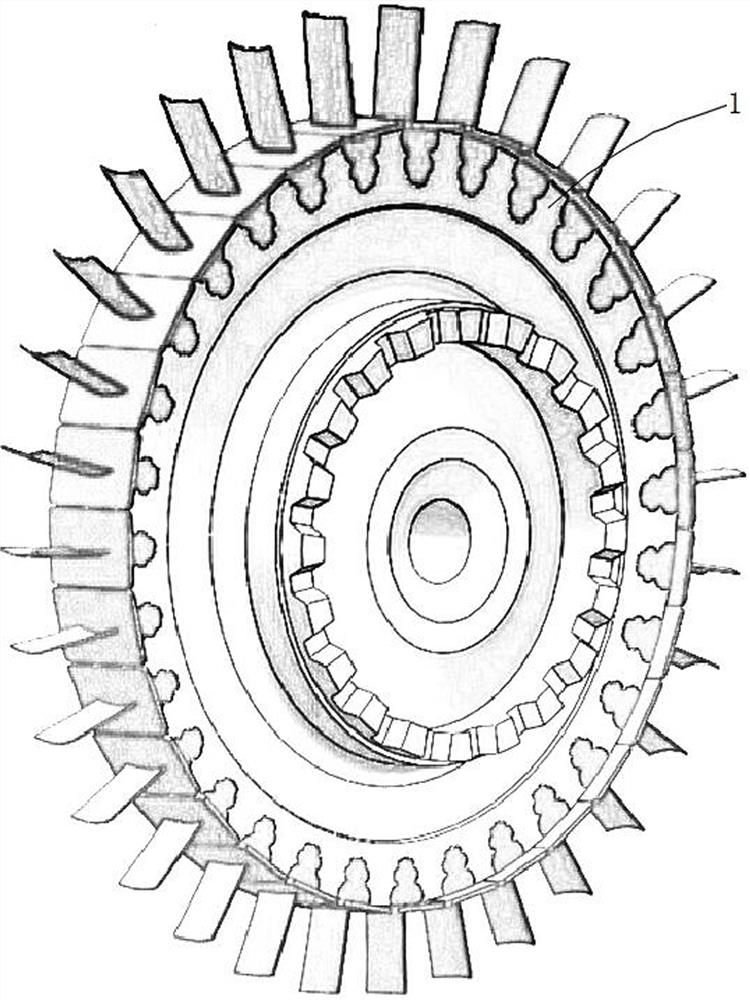

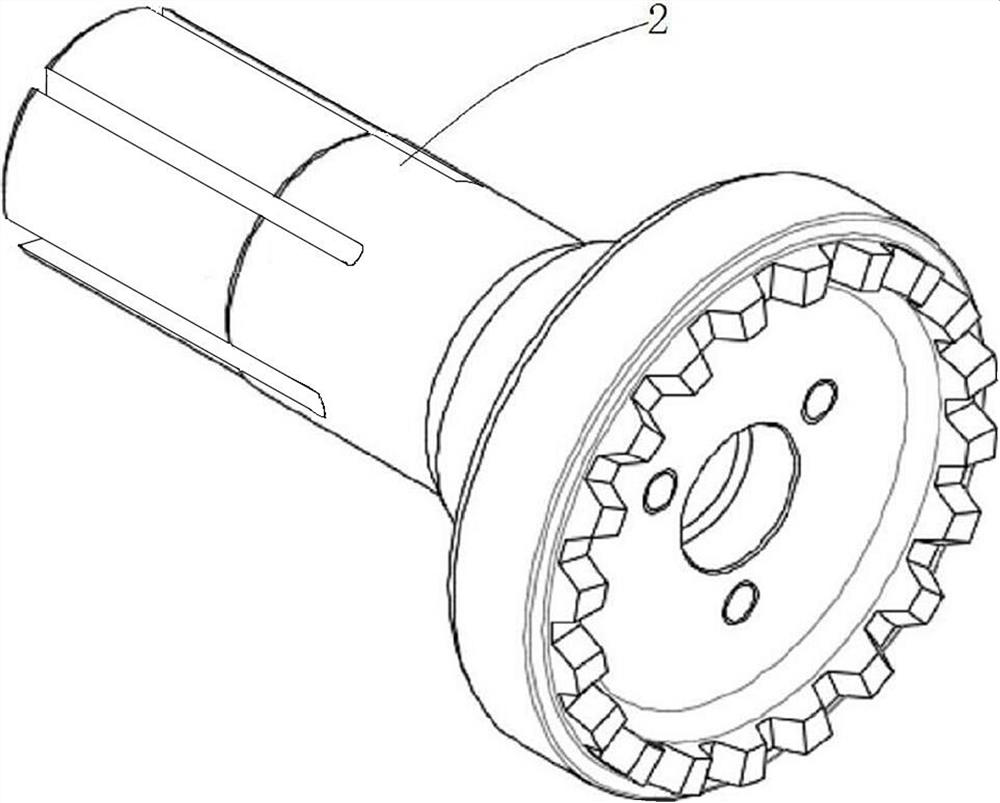

[0030] The main structure of this embodiment, such as Figure 1~4 As shown, the turbine disk blade assembly 1 includes a turbine disk in the middle, turbine blades are evenly distributed on the outer edge of the turbine disk, gear disks are arranged on both sides of the turbine disk, and it is characterized in that it includes a compressed turbine disk blade Assembly 1 and a positioning assembly for positioning it, the positioning assembly includes the first end tooth clamping part 2 on the left side, the second end tooth clamping part 3 on the right side, and the center that runs through the middle of the turbine disk blade assembly 1 Part 4, the right side of the first end tooth clamping part 2 and the left side of the second end tooth clamping part 3 are provided with end teeth, and are respectively highly meshed with the gear discs on both sides of the turbine disc; the center One end of the part 4 is fixedly connected with the first end tooth clamping part 2 through a scr...

Embodiment 2

[0034] In this embodiment, on the basis of the above embodiments, a fixed assembly is further added, such as figure 1 As shown, it also includes a fixing assembly for fixing the positioning assembly, the fixing assembly includes a first fixing sleeve 9 and a second fixing sleeve 10, the first end tooth clamping member 2 is embedded in the first fixing sleeve 9, and the The second end tooth clamping part 3 is embedded in the second fixed sleeve 10, and the first fixed sleeve 9 and the second fixed sleeve 10 are also provided with a compression ring 11 on the side close to the turbine disk blade assembly 1. The tight ring 11 is in close contact with the inner edge of the turbine disk of the turbine disk blade assembly 1 . Other parts of this embodiment are the same as those of the foregoing embodiment, and will not be repeated here.

Embodiment 3

[0036] On the basis of the above-mentioned embodiments, this embodiment further defines the structure of the fixing assembly, such as figure 1 As shown, the ends of the first end tooth clamping part 2 and the second end tooth clamping part 3 are provided with four long through slots extending to the middle of the shaft end, the first end tooth clamping part 2 and the second end tooth clamping part The middle part of the end tooth holder 3 is provided with a compression cross plate 12, and the compression cross plate 12 is inserted into the first end tooth holder 2 or the long through groove at the end of the second end tooth holder 3. The middle part of the end tooth clamping part 2 or the second end tooth clamping part 3, and press the first fixing sleeve 9 or the second fixing sleeve 10;

[0037] The middle part of the compression swash plate 12 embedded in the first end tooth clamping part 2 is penetrated by the central part 4, and the penetrating end of the central part 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com