Device for measuring vertical divergence angle of high-power laser diode array

A laser diode and vertical divergence angle technology, applied in the field of measurement devices, can solve the problems of low measurement accuracy, inability to introduce a circulating water system, and inability to maintain concentricity between the rotating shaft and the light-emitting line, achieving large redundancy and flexibility, The effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The device for measuring the vertical divergence angle of a high-power laser diode array according to the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

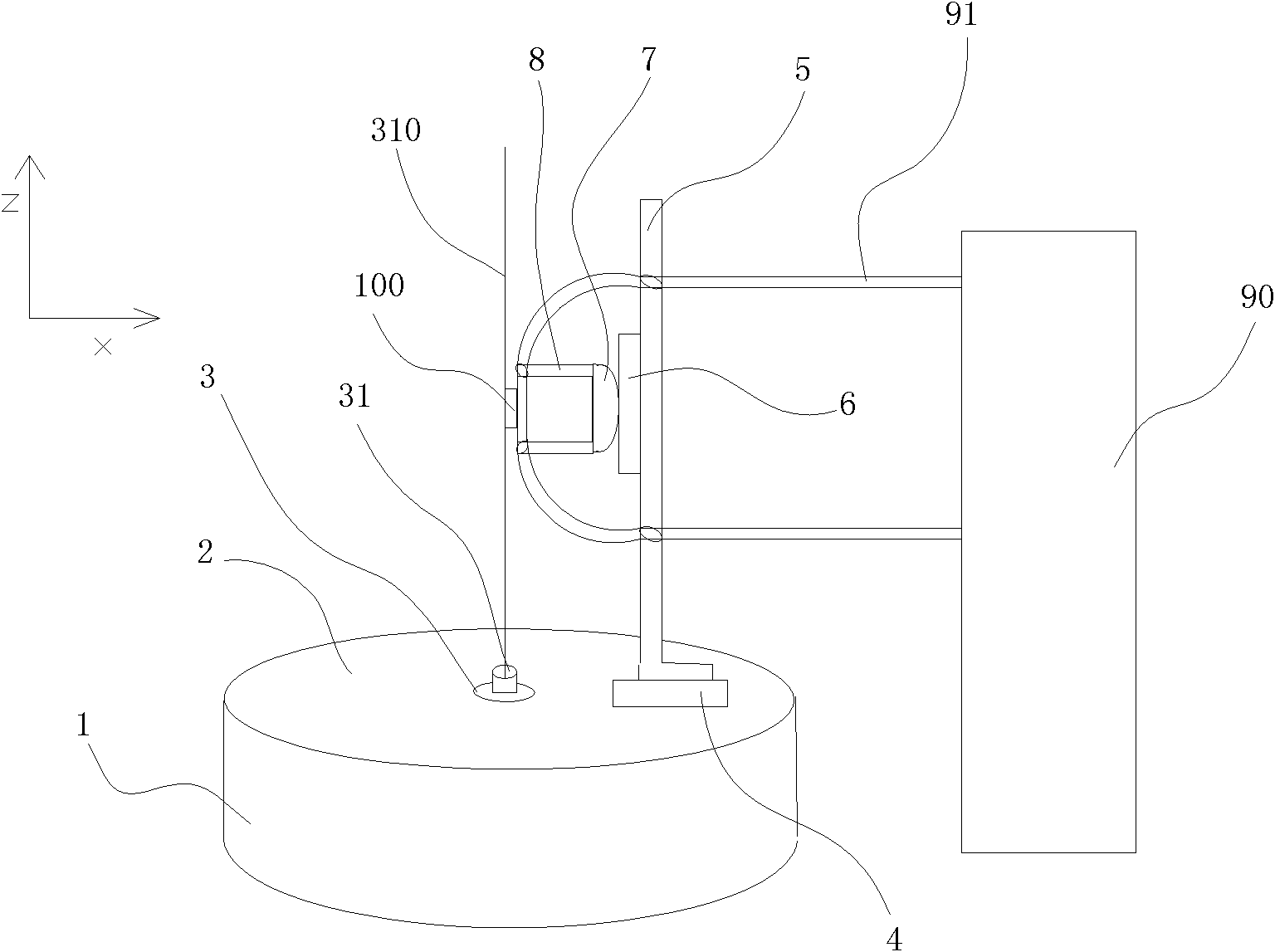

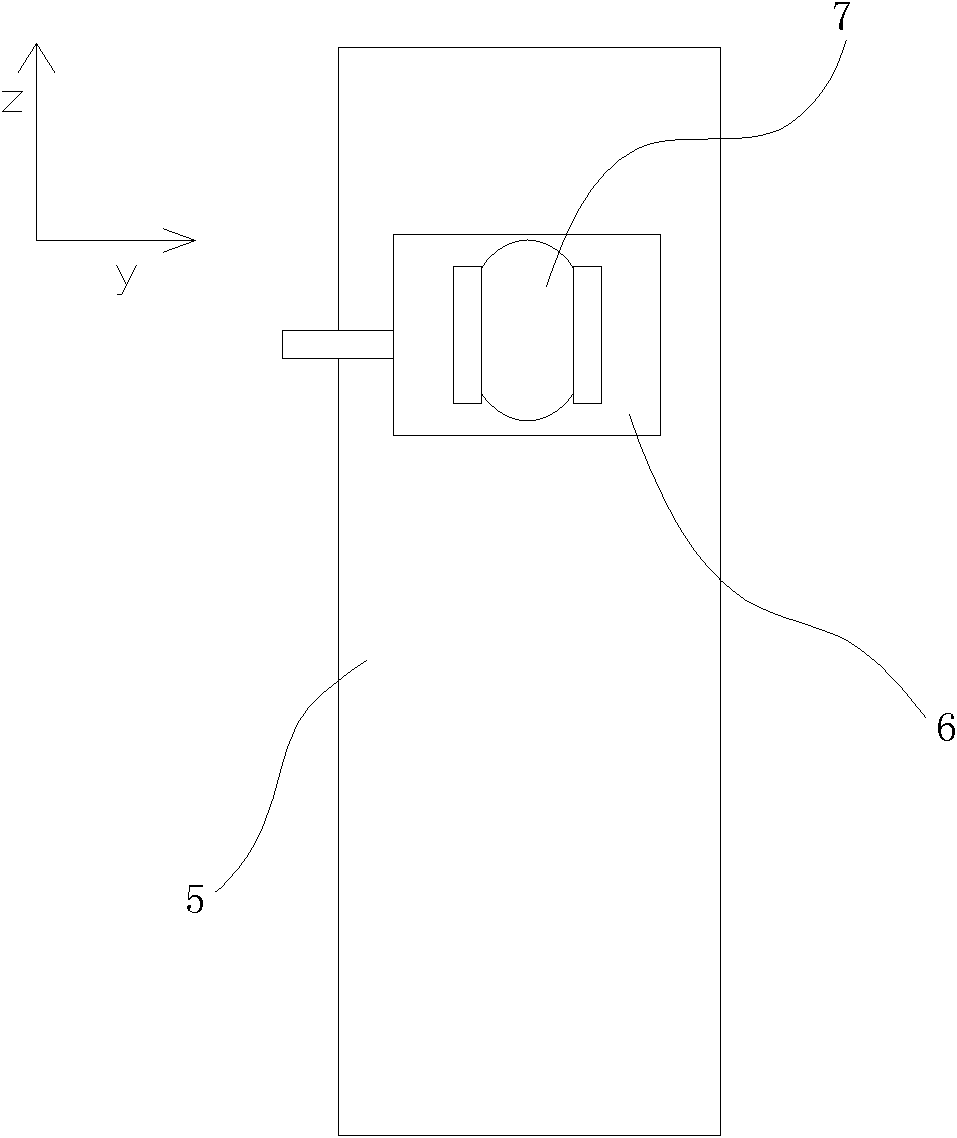

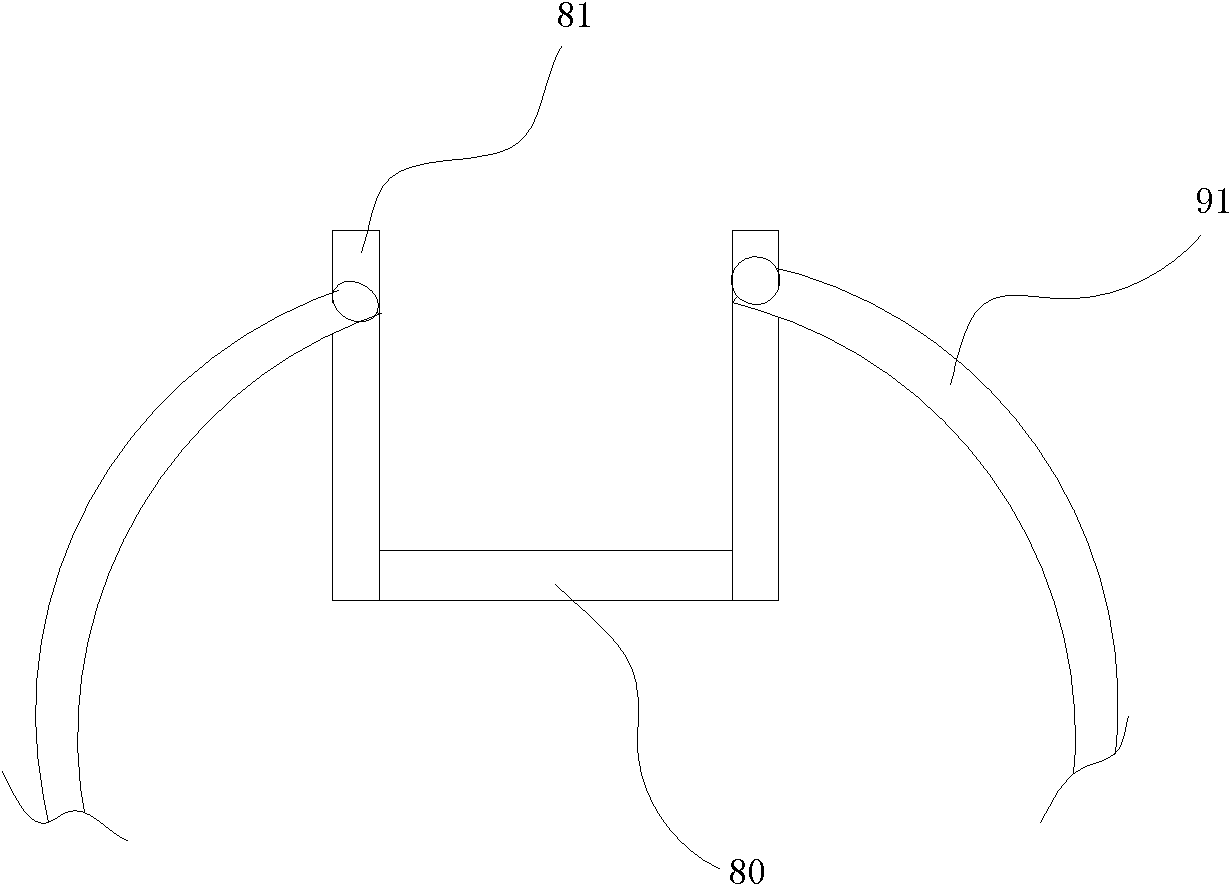

[0028] see figure 1 , figure 2 and image 3 As shown, the device of the invention includes a chassis 1, a rotating disk 2, a central axis 3, a first displacement regulator 4, a support 5, a second displacement regulator 6, a one-dimensional pitch regulator 7, a laser diode array support tooling 8 and Cooling system.

[0029] Wherein, the chassis 1 is a circular cylinder, and angle coordinates are engraved on the chassis 1. In a specific design, the angle on the chassis 1 is between -90° and +90°.

[0030] The rotating disk 2 is movably arranged on the chassis 1, and there is a scale mark on the surface of the rotating disk 2, so that when the relative position of the rotating disk 2 moves relative to the chassis 1, the correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com