Multi-surface integrated processing center

A machining center and integrated technology, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., to achieve the effects of saving equipment costs, reducing precision error problems, and reducing moving distances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

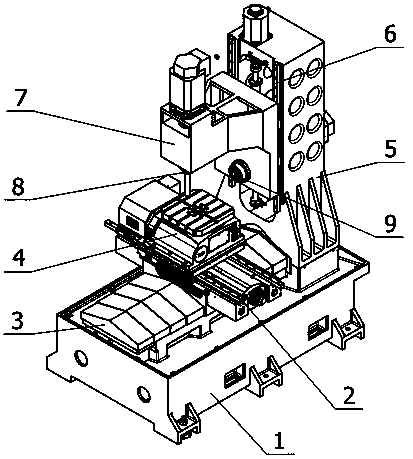

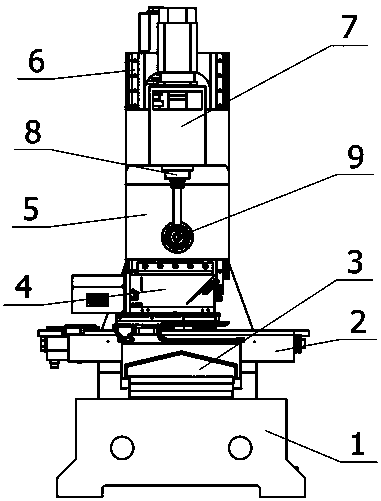

[0029] In the first embodiment, the X-axis slide rail and its screw drive system are arranged on the Y-axis slide rail and the screw drive system. According to the size and shape of the base and the different operating habits, the two can be set interchangeably.

[0030] A column is also arranged on the base, and a Z-axis guide rail and a Z-axis screw drive system are arranged on the column, and a servo motor driving the Z-axis direction is arranged on the top of the column. The Z-axis guide rail is provided with a spindle mounting frame. In Embodiment 1, the spindle mounting frame is an F-shaped structure, including a horizontal extension and a vertical extension at the top, and the middle part of the spindle mounting frame is a Z-axis screw pair.

[0031] The vertical spindle is arranged on the top of the horizontal extension of the spindle mounting seat, and the vertical spindle is arranged vertically downward. The structure is similar to a standard vertical machining cent...

Embodiment 2

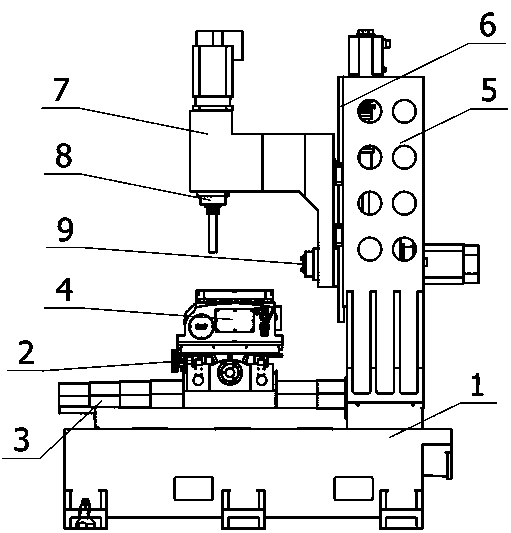

[0035] Embodiment 2 is an improved solution of Embodiment 1. Its bed, X-axis guide rail, Y-axis guide rail, and rotary table are all the same as Embodiment 1, and it is also a solution using a single column and a set of Z-axis guide rails. Its difference lies in: its main shaft mounting frame only has the horizontal extension part, and no vertical extension part is provided, and the vertical main shaft and the horizontal machining main shaft are all arranged on the top of the horizontal extension part. The two are integrated on the top of the horizontal extension of the spindle mounting frame in a mutually perpendicular manner.

[0036] Embodiment 2 is exactly the same as Embodiment 1 when the vertical spindle is working. When the horizontal spindle is working, the Z axis and the Y axis are used as the processing surface, and the X axis is used as the feed direction for horizontal processing.

[0037] In Embodiment 1 and Embodiment 2, when the vertical machining center and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com