Casing boss channel machining method based on characteristics

A processing method and channel technology, applied in the CAM field, can solve problems such as low programming efficiency, insufficient flexibility, and poor quality, and achieve the effects of high computing efficiency, high accuracy rate, and strong flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

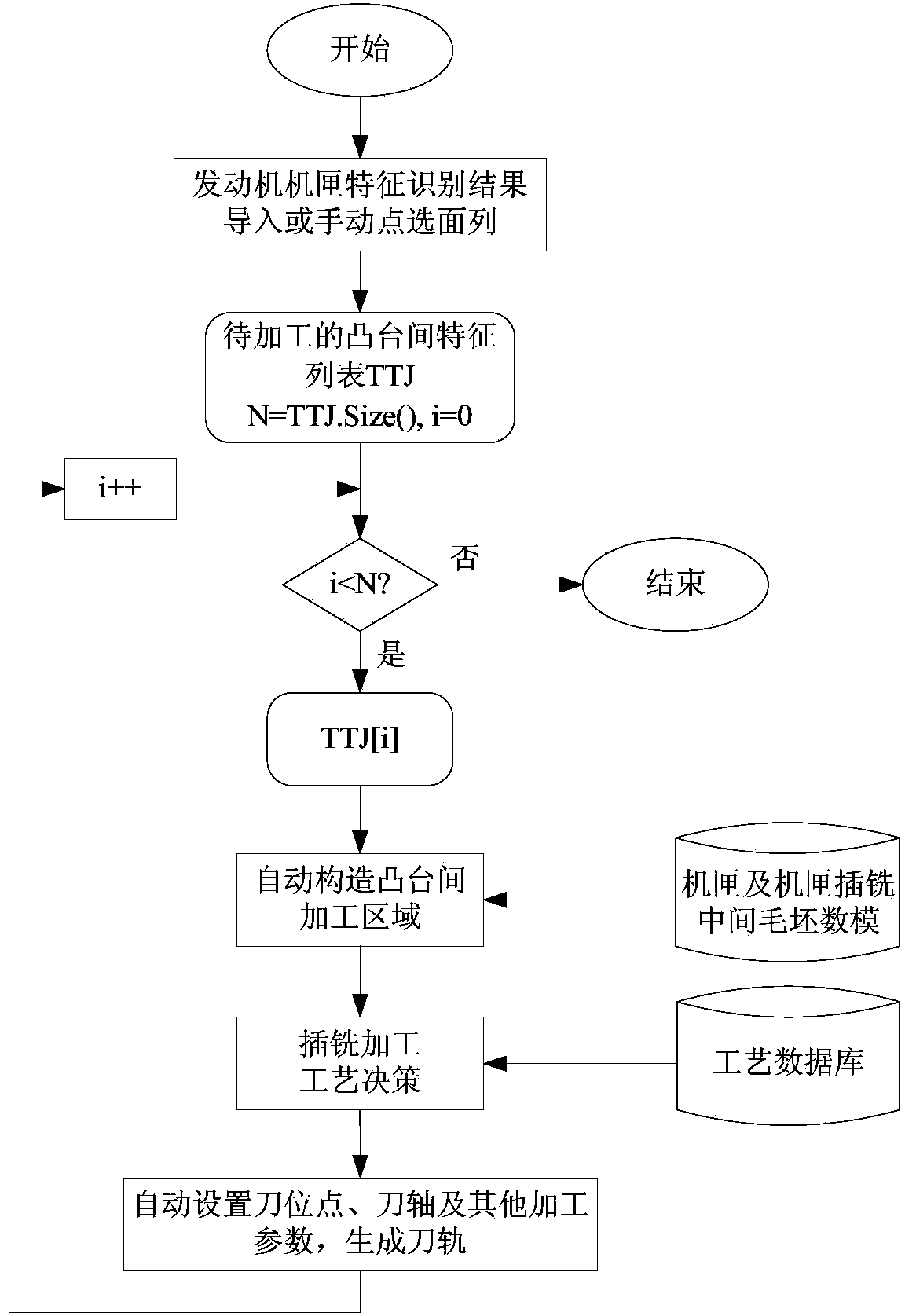

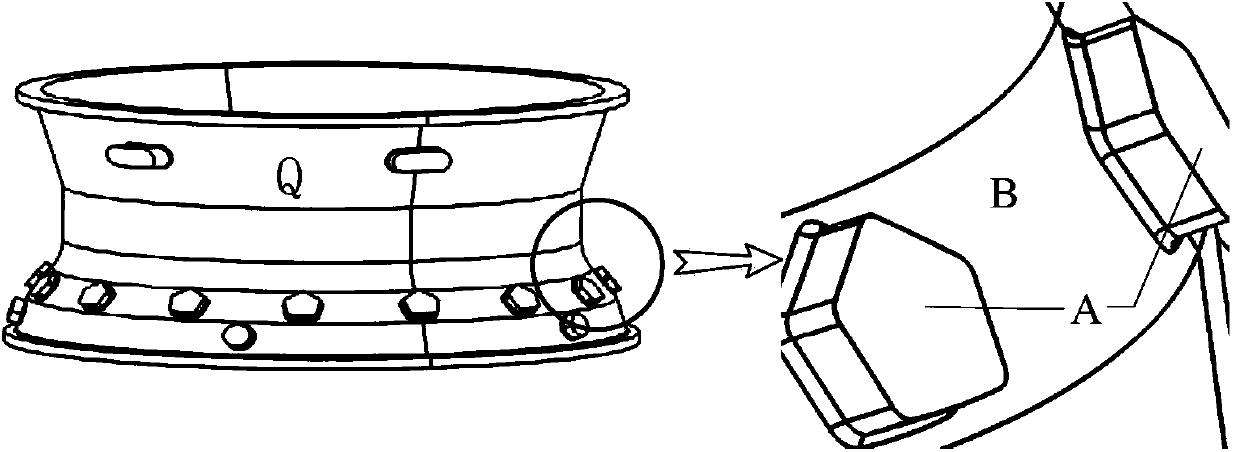

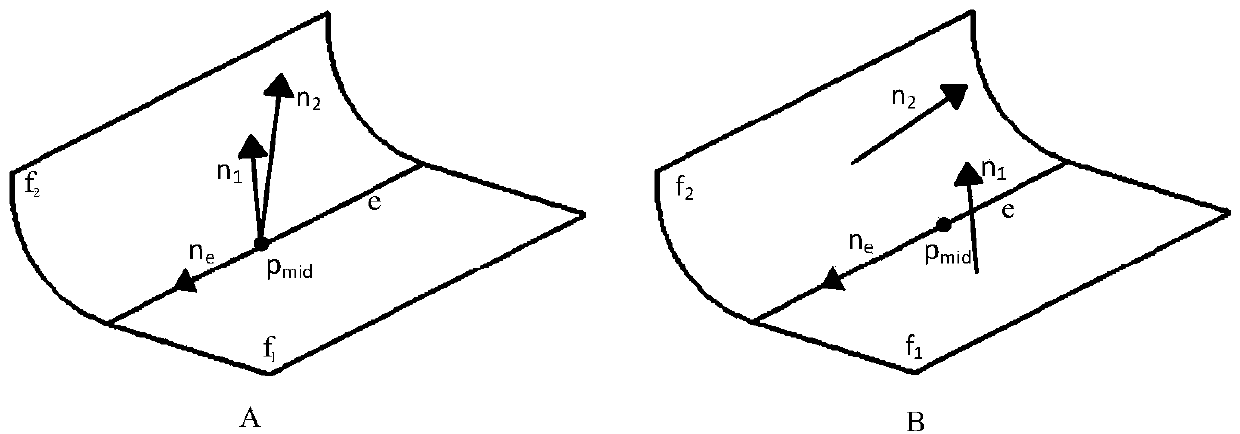

[0050] The present invention aims at the lack of a systematic processing mode for the channel between the bosses of the aero-engine casing in the current CAM system, that is, the combination of rough machining with plunging milling and finishing with layer milling, and the low efficiency, poor quality, and insufficient flexibility of existing machining programming. To solve this problem, a feature-based machining method for the convex channel of aero-engine casing is proposed. First read the casing model and casing feature recognition results, automatically build the processing area of the channel between the bosses, and then according to the data in the processing resource library, you can choose to automatically generate or manually input the rough and fine roughness and fineness of the channel between the bosses t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com