Rapid generating method of milling path of web of airplane structural member

A technology for aircraft structural parts and milling processing, applied in computer control, instruments, simulators, etc., can solve problems such as long programming time, low programming efficiency, and difficult identification, and achieve high computing efficiency, flexibility, and lightening. Effects of programming workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0065] Such as Figure 1-10 shown.

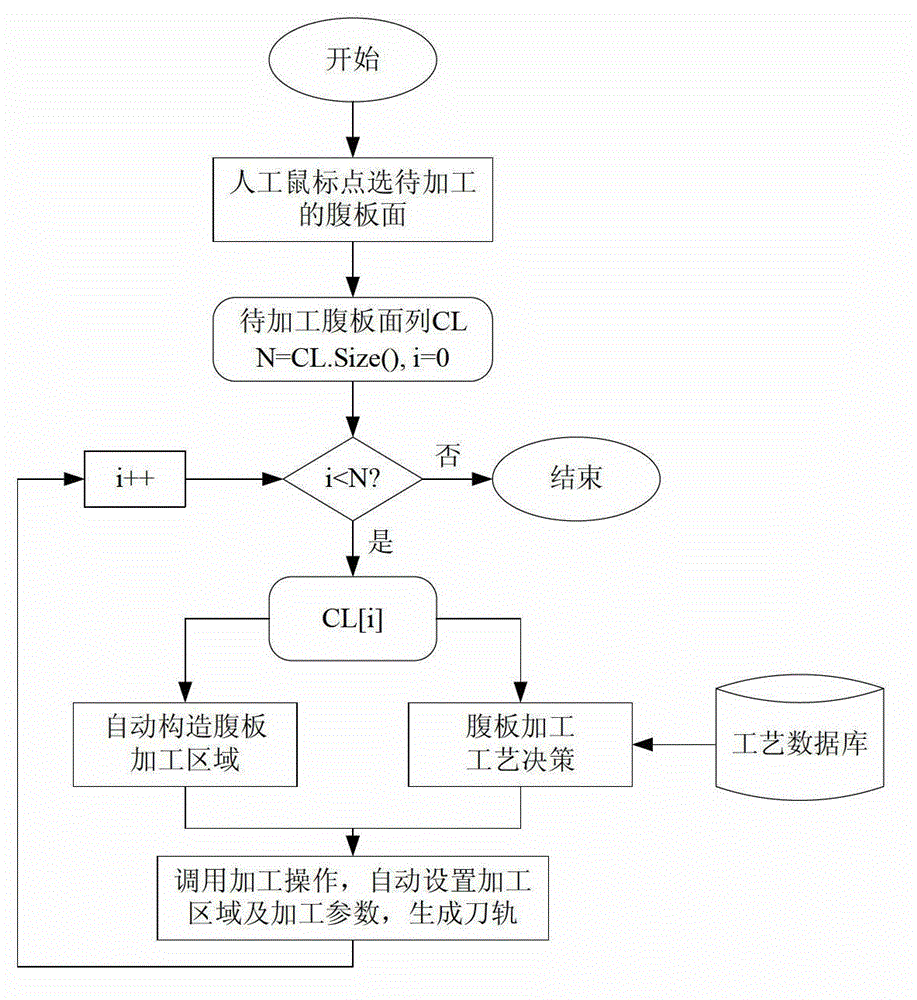

[0066] A method for quickly generating machining tracks for web milling of aircraft structural parts, the flow chart of which is shown in figure 1 shown, including the following steps:

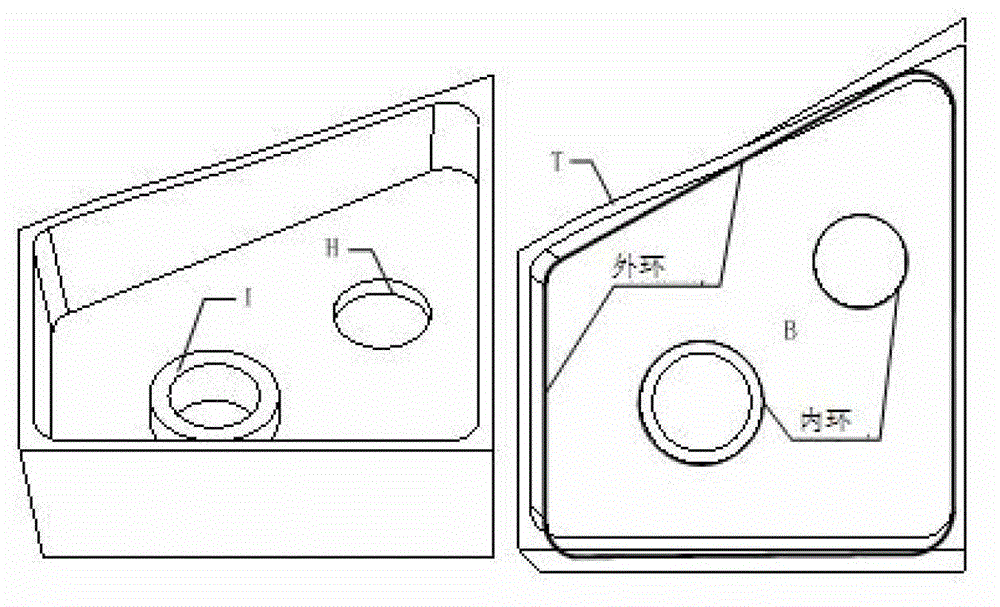

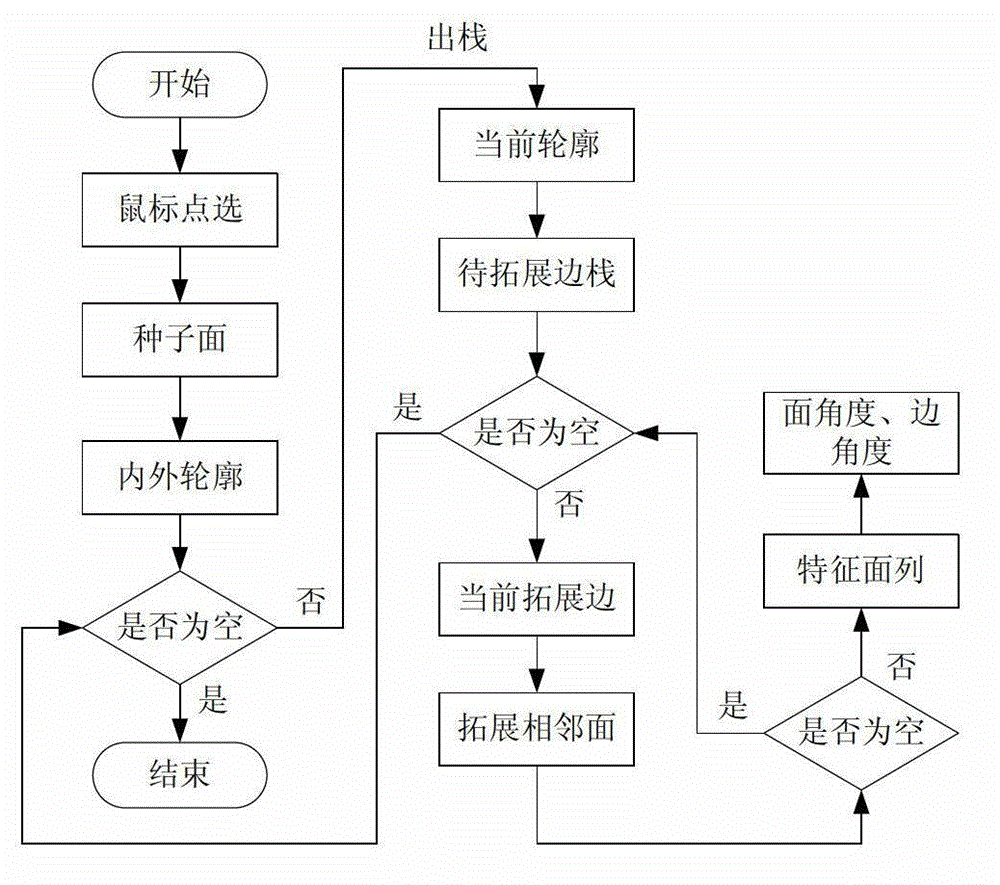

[0067] First, in the CAM environment, click the web surface to be processed by the mouse, and use the selected web surface as the seed surface to expand the surface to obtain the feature surface column corresponding to the web surface. Matching and constructing the columns to realize the automatic construction of the web milling processing area, such as figure 2 As shown, the processing parameters are determined through process decision-making; finally, the geometric elements constituting the processing area and the results of process decision-making are automatically assigned to the corresponding processing operations in the CA...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com