Method for determining self-adaptive outline surrounding milling tool path according to peak characteristics of complex structural member

A technology for determining methods and structural parts, applied in the field of CNC machining of parts, can solve problems such as poor processing quality and low processing efficiency, and achieve the effects of improving processing quality, improving processing efficiency, and improving processing quality and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047]The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0048] Such as figure 1 ‐9.

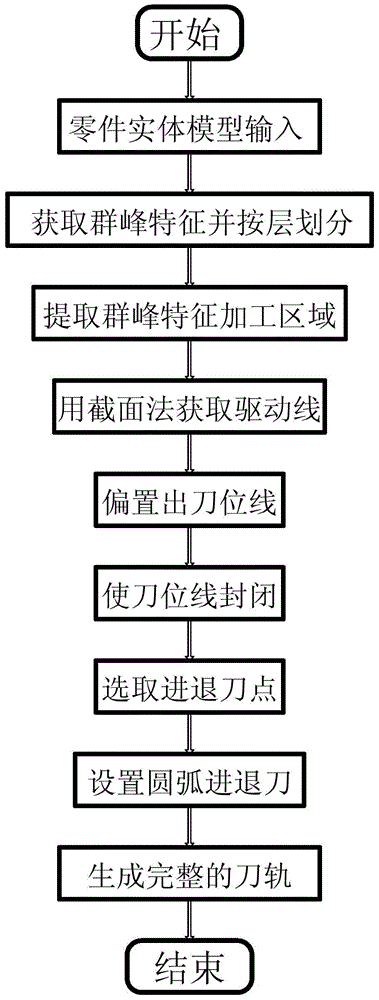

[0049] A tool path determination method for milling complex structural parts with group peak features around its contour, the whole steps are as follows figure 1 As shown, it includes the following ten steps:

[0050] Step 1. Input the solid model of the part and set the processing coordinate system.

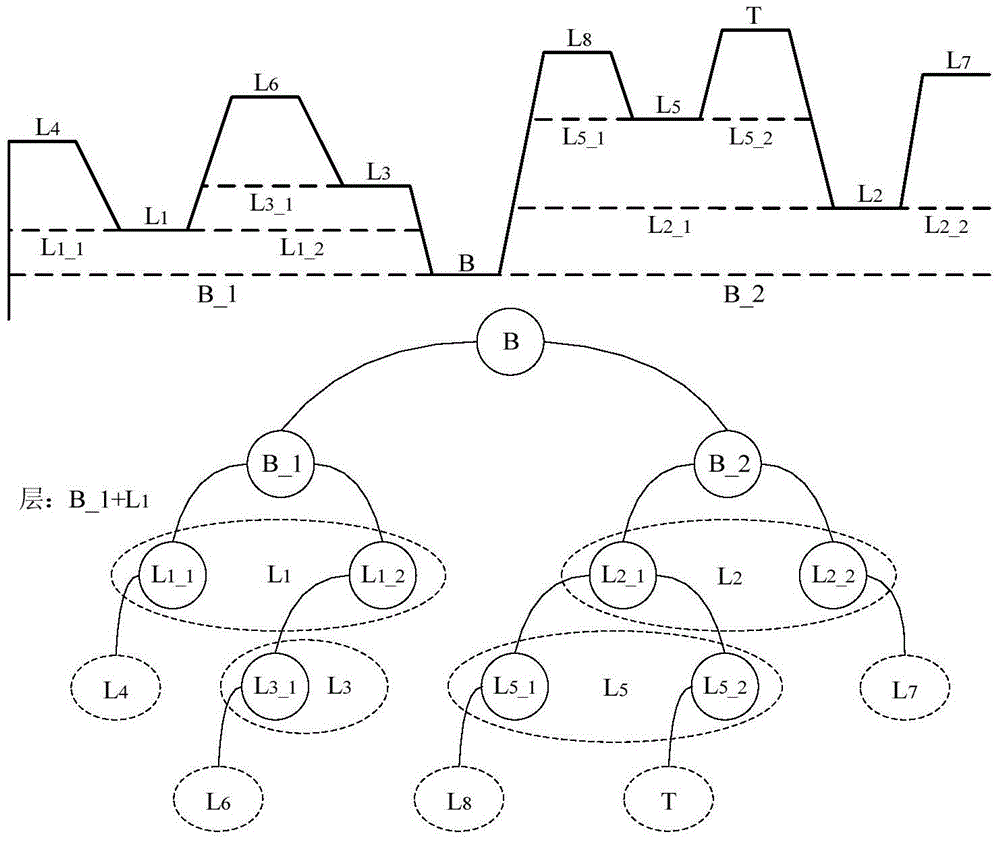

[0051] Step 2. Obtain the group peak features and divide the group peak features into layers.

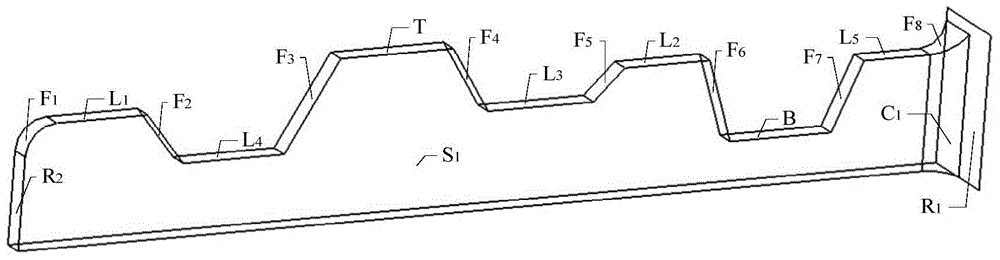

[0052] The peak characteristics of this embodiment are as Figure 8 As shown, the acquisition of the group peak features adopts the method of combining manual interaction and automatic identification: first, click the side in the part solid model to determine the group peak feature to be processed, and automatically identify other geometric features contained in the group peak feature according to the selected side. Elements,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com