Energy-saving automatic control system and method of evaporative type cooling/condensing device

An automatic control system, evaporative cooling technology, applied in heat exchange equipment, lighting and heating equipment, etc., can solve problems affecting the stable operation of equipment, operation delay or error, low work efficiency, etc., to achieve low hardware configuration requirements and cost. low, the effect of improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further explained below in conjunction with specific embodiments.

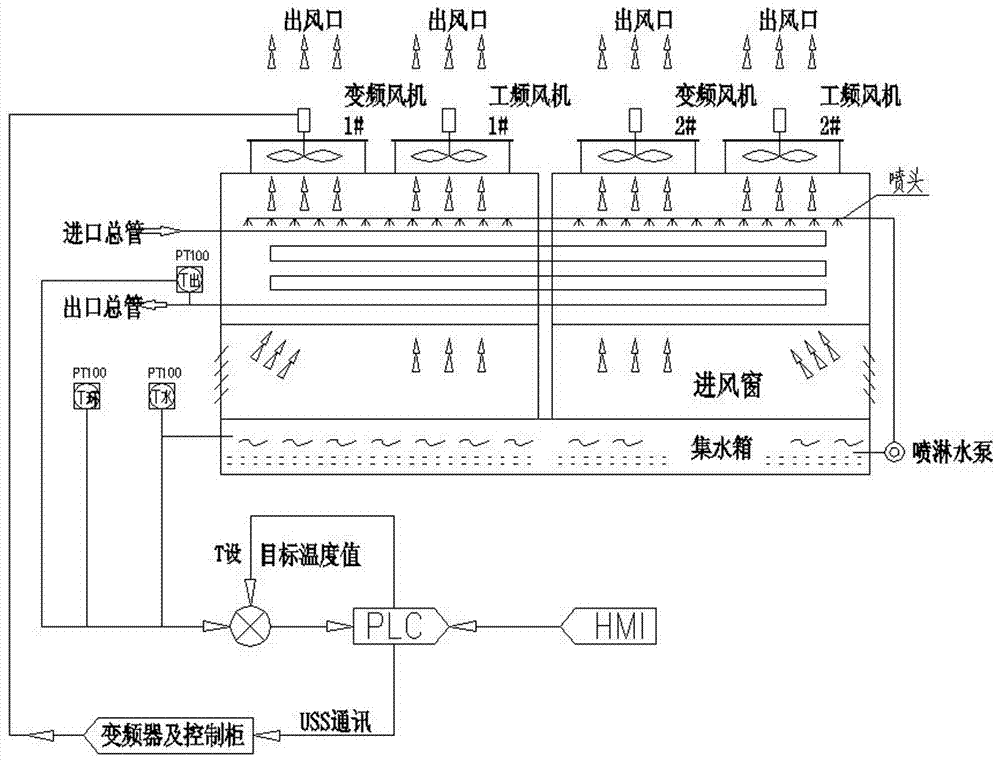

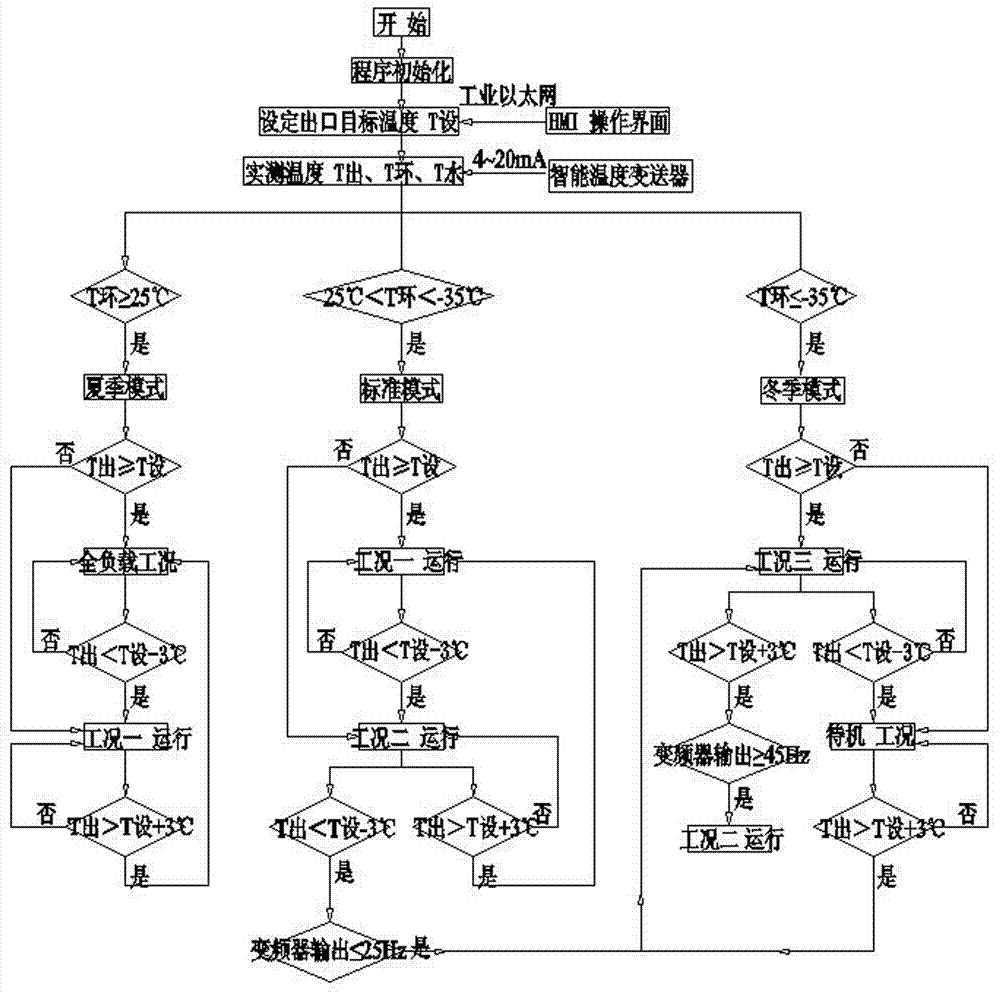

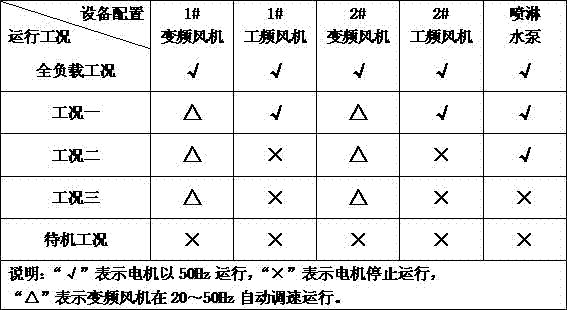

[0022] Such as figure 1 Shown: An energy-saving automatic control system for evaporative cooling / condensing equipment. The equipment configuration includes two variable-frequency fans, two power frequency fans, and a spray water pump, all equipped with high-efficiency energy-saving motors;

[0023] The temperature measuring element of the intelligent temperature transmission selects PT100 thermal resistance temperature sensor, including the ambient temperature transmitter, the outlet main pipeline medium temperature transmitter, and the collecting tank temperature transmitter.

[0024] The ambient temperature transmitter is set on the evaporative cooling / condensing equipment platform for real-time monitoring of the equipment site ambient temperature, using T ring Means

[0025] The medium temperature transmitter of the outlet main pipe is set on the outlet main pipe of the evapora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com