Explosive-removing unmanned aerial vehicle

A technology of unmanned aerial vehicles and airframes, applied in the field of special unmanned aerial vehicles, can solve the problems of slow walking speed, low threat in urban areas, and high risk of passing through, and achieve the effect of avoiding the formation of sparks and reducing the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

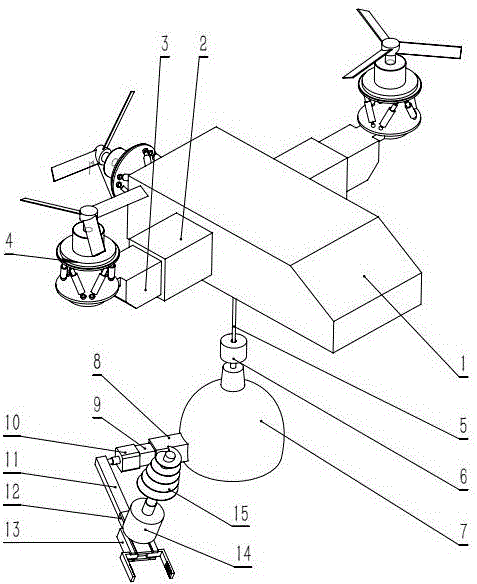

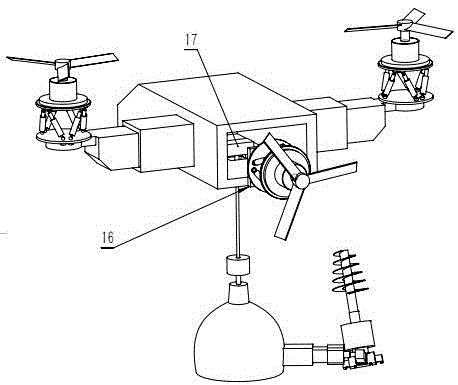

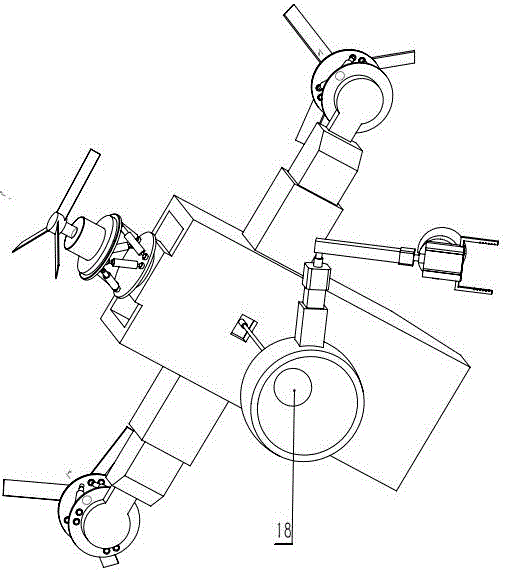

[0021] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, an EOD drone includes a body 1, two first square sleeves 2, two first telescopic rods 3, three power components 4, a steel wire rope 5, a first servo motor 6, and a bell housing 7. The second square sleeve 8, the second telescopic rod 9, the second servo motor 10, the swing rod 11, the third servo motor 12, the pneumatic gripper 13, the DC motor 14, the conical auger bit 15, and the rear mount 16. Hoist 17, high-pressure water blasting device 18, characterized in that: the body 1 is a cuboid structure, the head is pointed, and a first square sleeve 2 is installed on the left and right sides of the body 1, each A first telescopic rod 3 is slidably installed in the first side sleeve 2, and a power assembly 4 is installed above the outer end of the first telescopic rod 3, and a power assembly 4 is also provided at the rear of the body 1, and the power assembly 4 Installed on the rear portion of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com