Pneumatic finger with replaceable contact

A technology of pneumatic fingers and contacts, applied in manipulators, chucks, manufacturing tools, etc., can solve the problems of difficulty in completing complex and fine movements, the influence of pneumatic fingers on the accuracy of movements, and the difficulty in adjusting the contact force of the grasping point. Take the effect of flexibility, better anti-skid effect and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

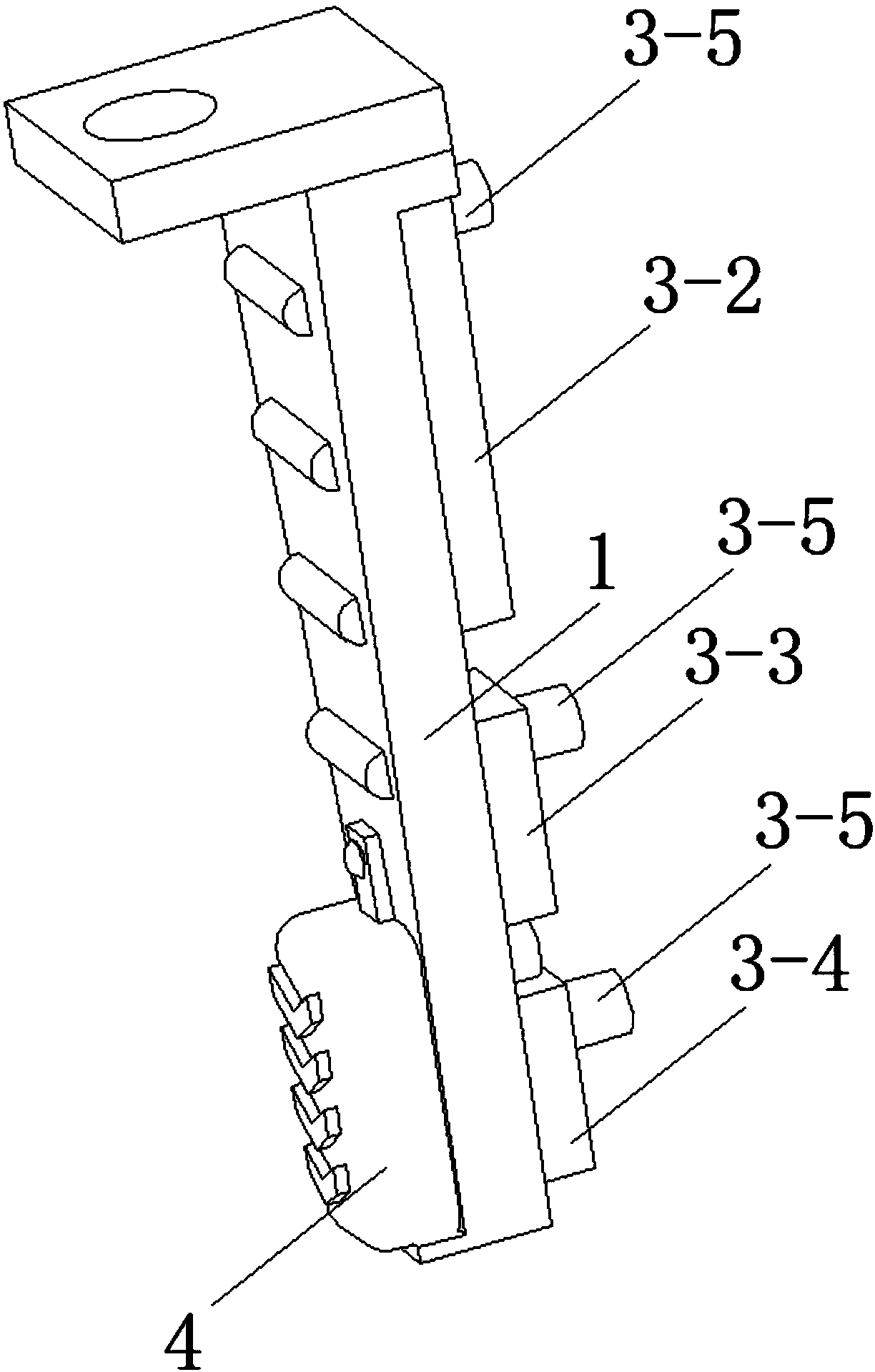

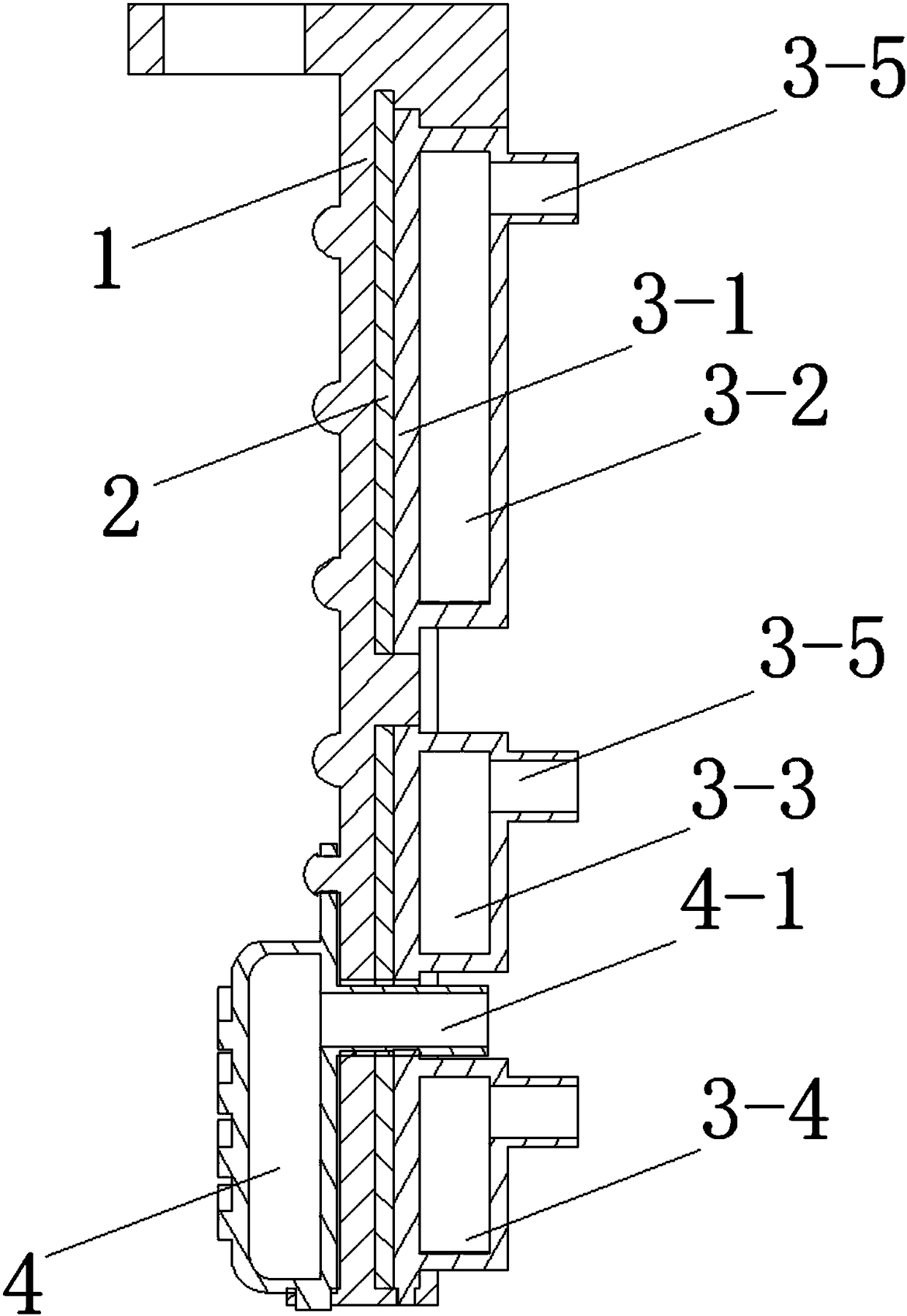

[0030] See Figure 1 to Figure 5 , the pneumatic finger with replaceable contacts in this embodiment includes a base frame 1 , a supporting shrapnel 2 , an outer drive assembly 3 and a detachable contact 4 .

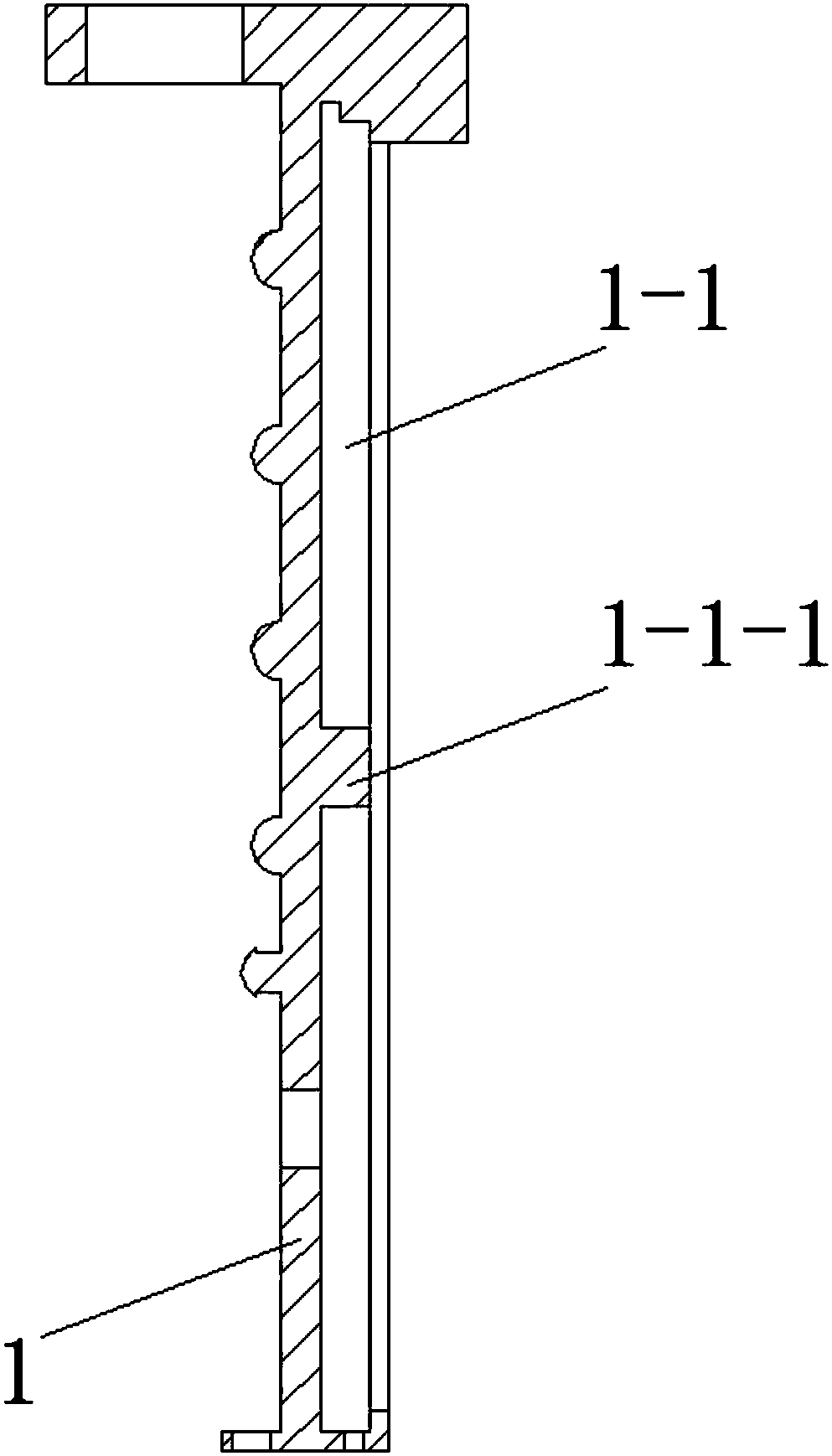

[0031] The bottom of the base frame 1 is mounted on the end of the robot. The width of the base frame 1 gradually decreases from top to bottom. The supporting elastic piece 2 is arranged in the base skeleton 1 . The outer drive assembly 3 includes a base sheet 3-1 and a bottom-finger drive cavity 3-2, a middle-finger drive cavity 3-3 and a fingertip drive cavity 3- 5. The substrate sheet 3-1 is detachably fixed on one side of the substrate skeleton 1 . The driving cavity 3-2 for the base of the finger, the driving cavity 3-3 for the middle finger and the driving cavity 3-5 for the fingertip are all provided with air pipes 3-5 communicating with the respective inner cavities. The finger root drive cavity 3-2, the middle finger drive cavity 3-3 and the fingertip drive...

Embodiment 2

[0037] This embodiment is basically the same as Embodiment 1, except that the detachable contact 4 is a solid structure with elasticity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com