Method for implementing automatic casting discharging through cooperation of three-dimension vision and robot

A technology of three-dimensional vision and automatic unloading, which is applied in the direction of conveyor objects, object destacking, computer parts, etc., and can solve the problems of random position and posture, multi-layer stacking, non-automation, and low versatility. , to achieve the effect of saving labor cost, high practicability and flexible grasping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

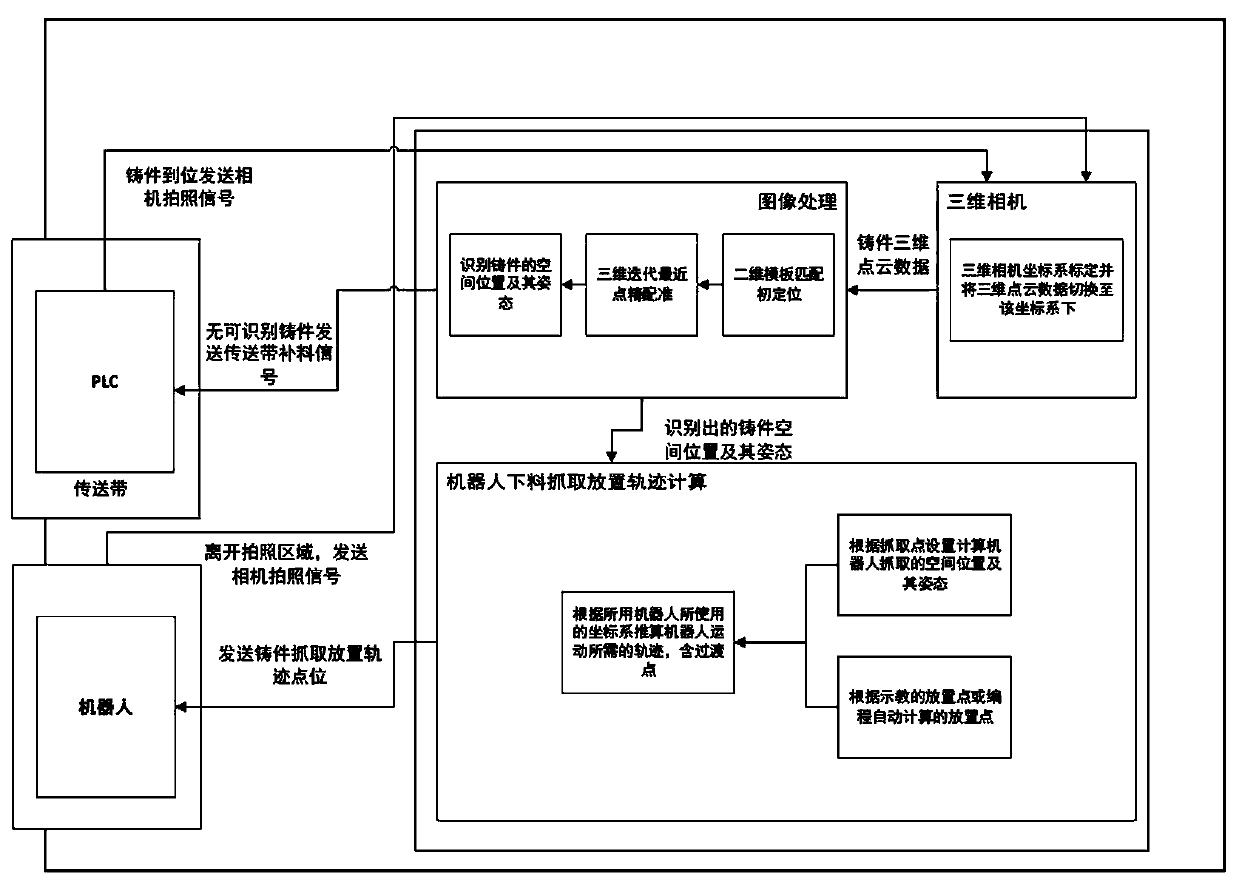

[0030] The method of the present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings.

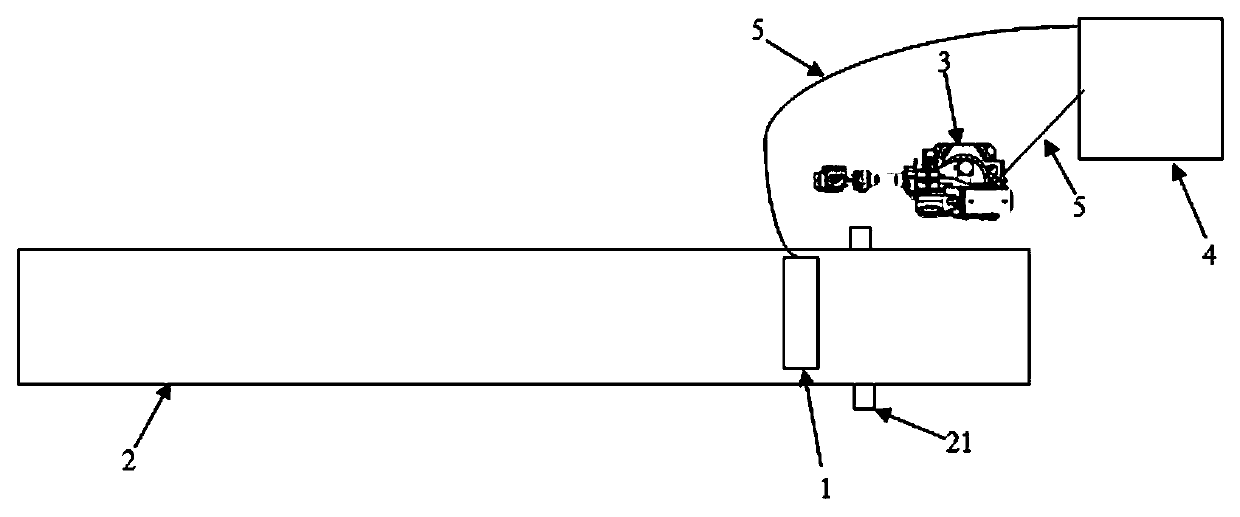

[0031] figure 1 Shown is the device for implementing the method of the present invention, including a three-dimensional camera 1 , a transmission mechanism 2 , a photoelectric sensor 21 , an industrial robot 3 , an industrial computer 4 and a communication network cable 5 .

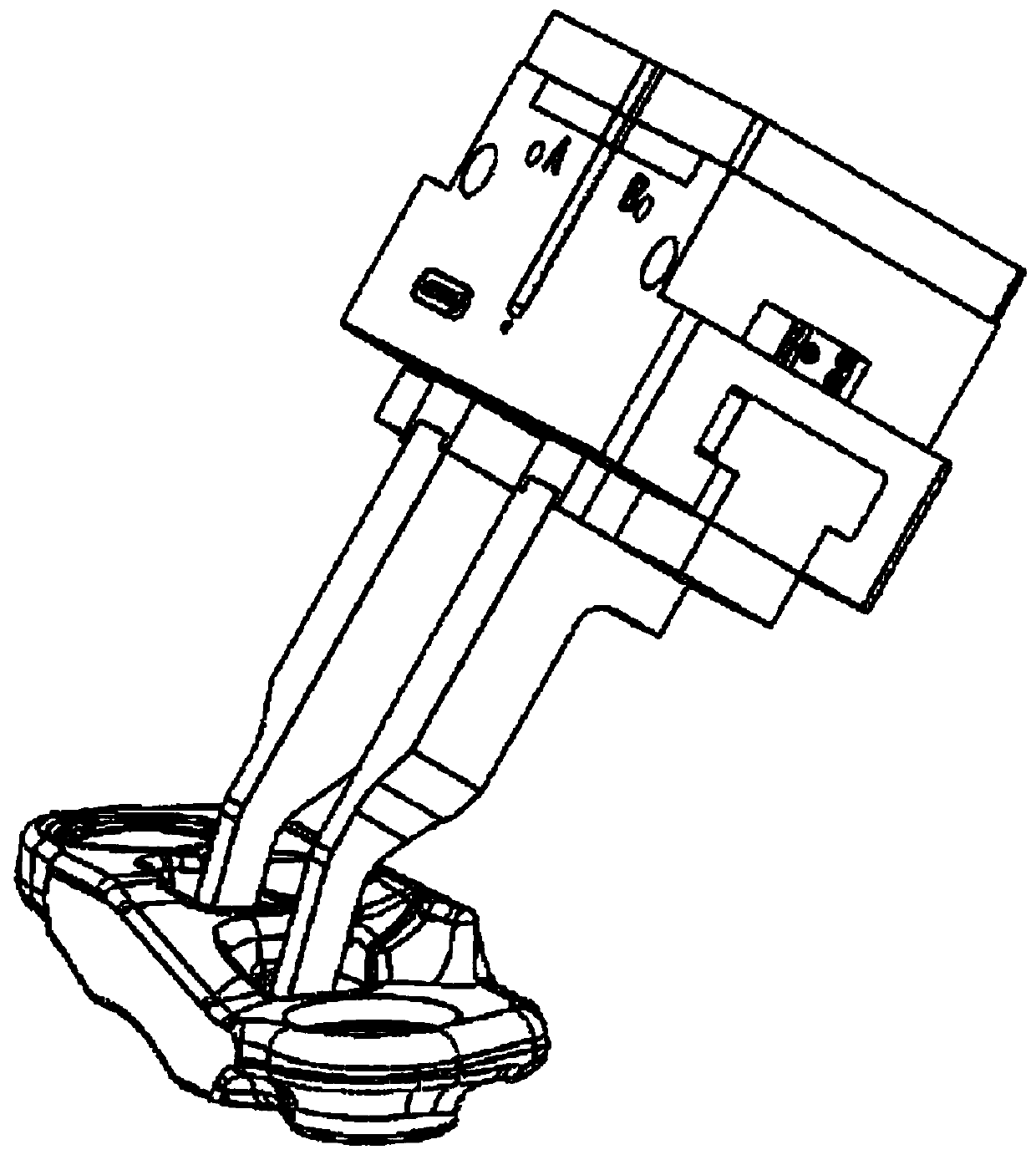

[0032] Among them, robot 4 is a general-purpose six-joint series industrial robot, which has general-purpose industrial robot functions, such as coordinate systems including joint coordinate system, rectangular coordinate system, tool coordinate system and external coordinate system, etc., and can establish and set the external coordinate system Wait.

[0033] The 3D camera 1 has the function of taking pictures in real time and acquiring 3D point cloud data. The real-time output of the 3D point cloud data output by the 3D camera 1 is transmitted to the indu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com