Automatic grabbing and lifting device for logistics sorting assembly line

An assembly line and logistics technology, applied in the direction of packaging, conveyor objects, transportation and packaging, etc., can solve the problems of low work efficiency, inability to meet the efficiency of logistics item sorting, time-consuming and labor-intensive, etc., and achieve the effect of convenient grabbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

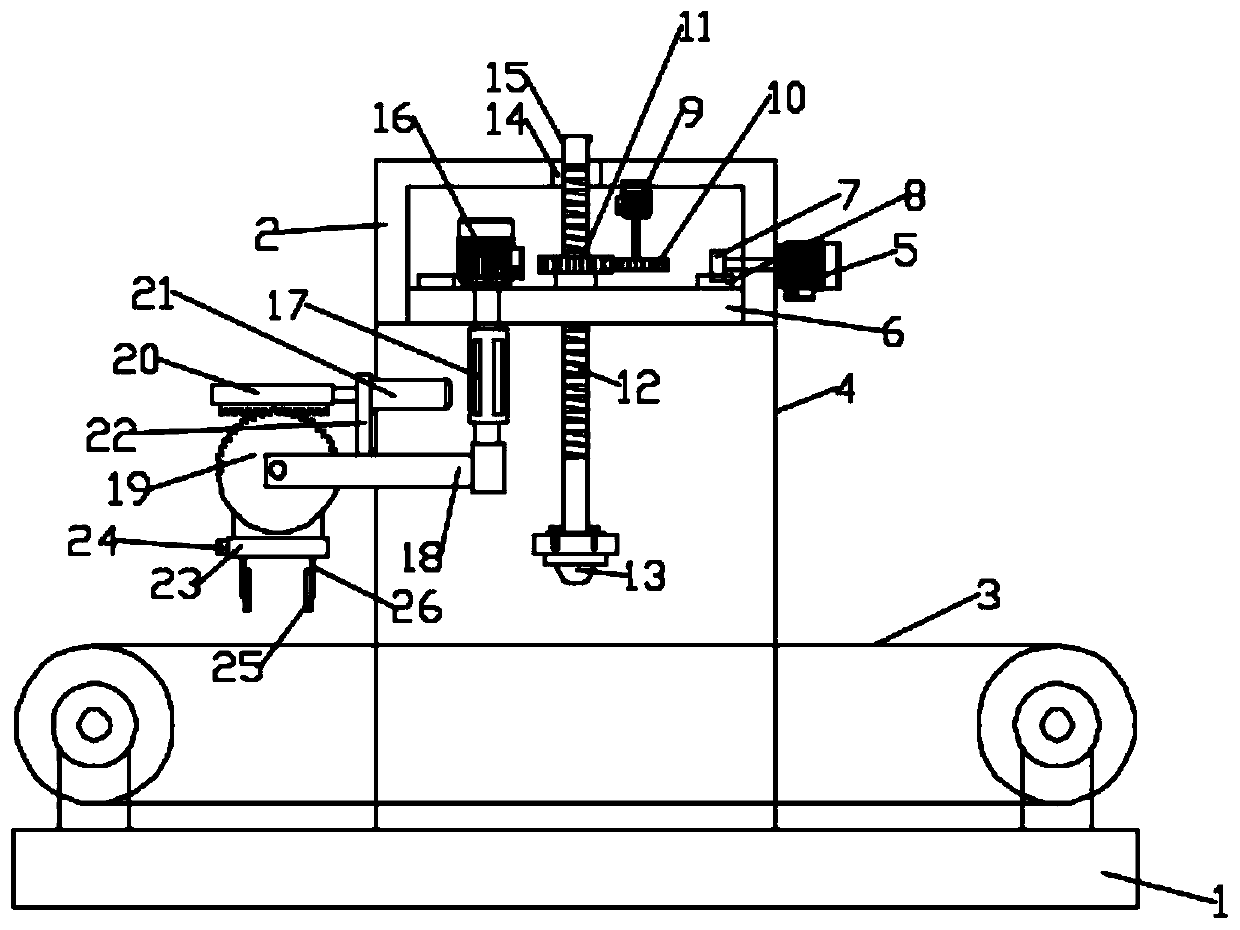

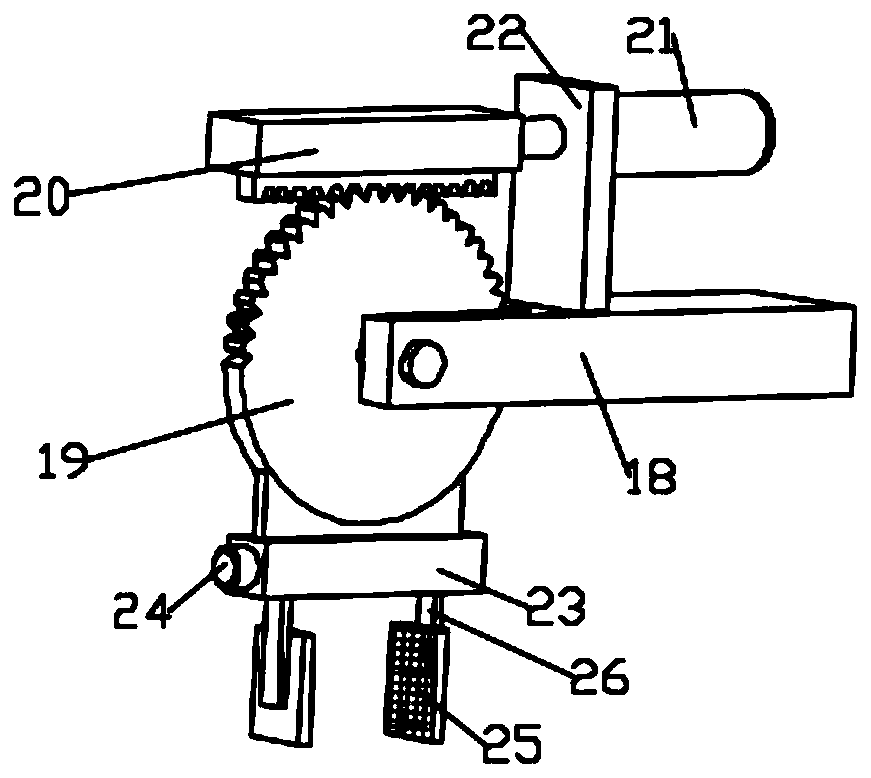

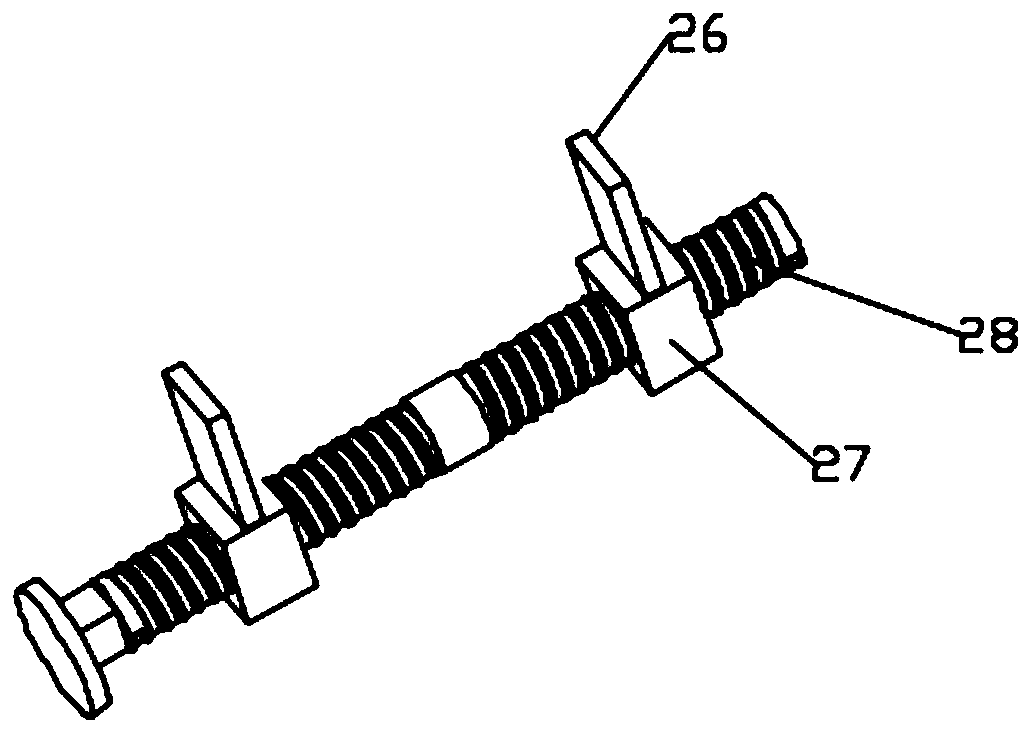

[0022] Such as figure 1 As shown, in the embodiment provided by the present invention, an automatic grabbing and lifting device for a logistics sorting line includes a base 1 on which a conveyor belt 3 is provided, and on the base 1 is also provided with Support the back plate 4, the top of the support back plate 4 is fixedly provided with a support top seat 2, and the bottom opening of the support top seat 2 is rotatably provided with a rotating disk 6, and the rotating disk 6 is provided with a device for adjusting infrared rays. The height adjustment assembly of the height position of the code scanning camera 13; one side of the rotating disk 6 is provided with a second forward and reverse servo motor 16, and the output shaft of the second forward and reverse servo motor 16 is provided with a vertical Electric telescopic rod 17, the telescoping end of described vertical electric telescopic rod 17 is provided with the angle adjusting assembly that is used to adjust the incli...

Embodiment 2

[0025] Such as figure 1 As shown, in the embodiment provided by the present invention, an automatic grabbing and lifting device for a logistics sorting line includes a base 1 on which a conveyor belt 3 is provided, and on the base 1 is also provided with Support the back plate 4, the top of the support back plate 4 is fixedly provided with a support top seat 2, and the bottom opening of the support top seat 2 is rotatably provided with a rotating disk 6, and the rotating disk 6 is provided with a device for adjusting infrared rays. The height adjustment assembly of the height position of the code scanning camera 13; one side of the rotating disk 6 is provided with a second forward and reverse servo motor 16, and the output shaft of the second forward and reverse servo motor 16 is provided with a vertical Electric telescopic rod 17, the telescoping end of described vertical electric telescopic rod 17 is provided with the angle adjusting assembly that is used to adjust the incli...

Embodiment 3

[0031] Such as figure 1 As shown, in the embodiment provided by the present invention, an automatic grabbing and lifting device for a logistics sorting line includes a base 1 on which a conveyor belt 3 is provided, and on the base 1 is also provided with Support the back plate 4, the top of the support back plate 4 is fixedly provided with a support top seat 2, and the bottom opening of the support top seat 2 is rotatably provided with a rotating disk 6, and the rotating disk 6 is provided with a device for adjusting infrared rays. The height adjustment assembly of the height position of the code scanning camera 13; one side of the rotating disk 6 is provided with a second forward and reverse servo motor 16, and the output shaft of the second forward and reverse servo motor 16 is provided with a vertical Electric telescopic rod 17, the telescoping end of described vertical electric telescopic rod 17 is provided with the angle adjusting assembly that is used to adjust the incli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com