Small-bag-grabbing packing machine

A type of box packing machine and box blank technology, applied in the field of small bag grabbing box packing machine, to achieve the effect of flexible grabbing, reliable performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

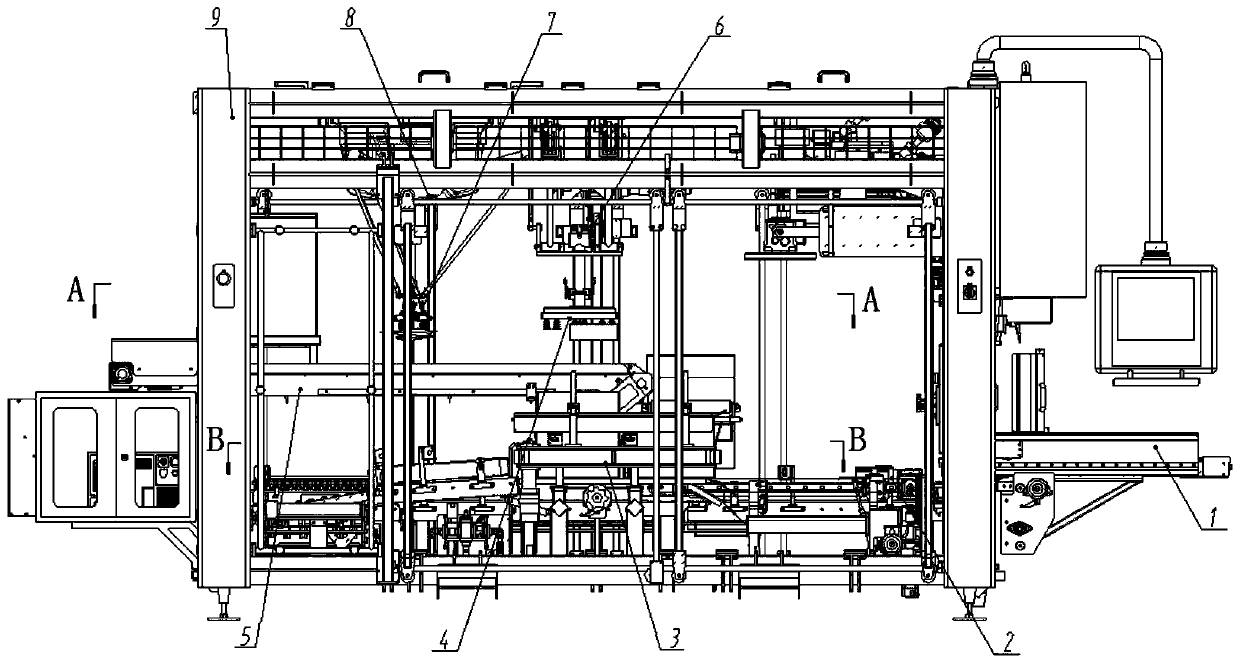

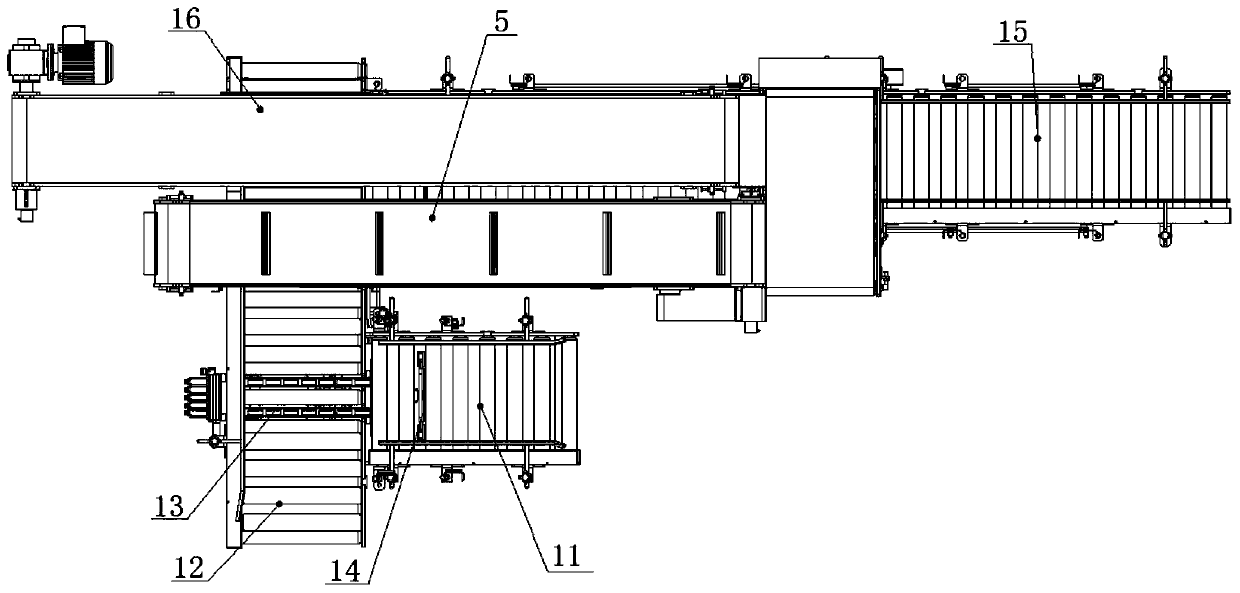

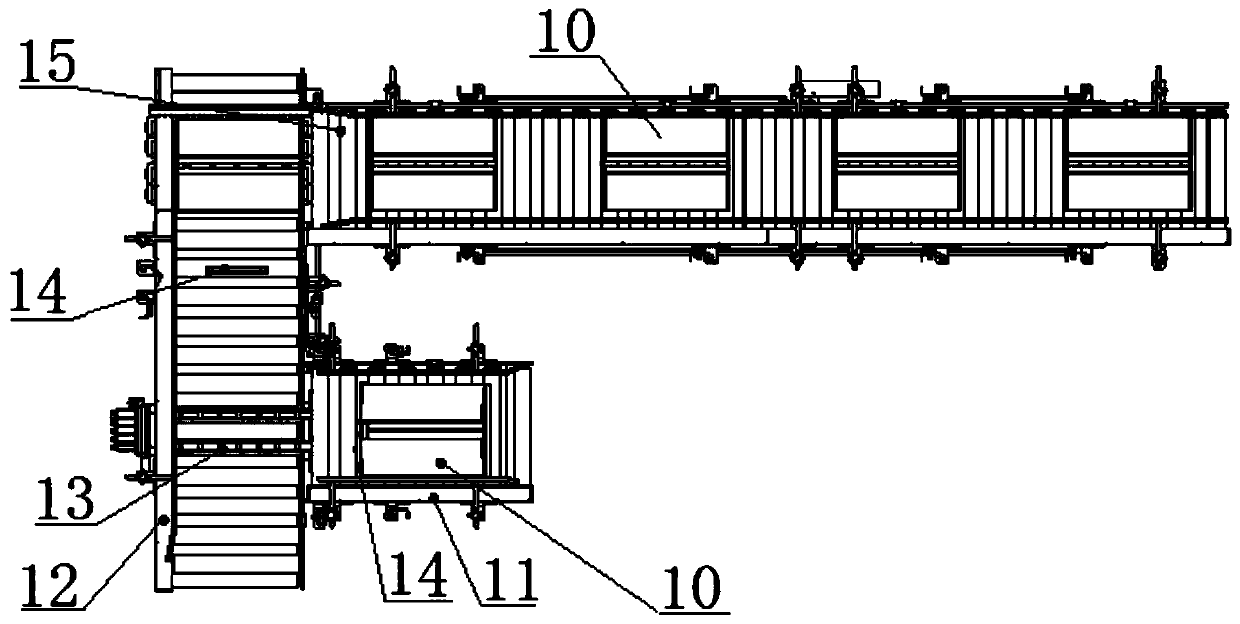

[0041] refer to Figure 1 to Figure 9 As shown, a small bag grabbing type cartoning machine in an embodiment provided by the present invention includes a frame part 9, and a carton blank conveying mechanism 1 connected to the frame part 9, a box blank suction forming mechanism 2, The carton conveying positioning mechanism 3, the material conveying belt conveyor 16, the material arranging belt conveyor 5, the first robot 6 and the second robot 8, the input end of the material conveying belt conveyor 16 is docked with the front conveying production line, and the material arranging belt conveyor 5 is arranged on the material On one side of the conveyor belt conveyor 16, the first robot 6 is arranged above the material arrangement belt conveyor 5 and the material delivery belt conveyor 16, and the first robot 6 grabs the scattered materials from the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com