High-precision quick reaction mechanical hand

A fast-response, manipulator technology, applied in the field of manipulators, can solve the problems of low flexibility, large workload, time-consuming and labor-intensive, etc., and achieve the effect of saving labor costs, flexible use, and reducing use costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

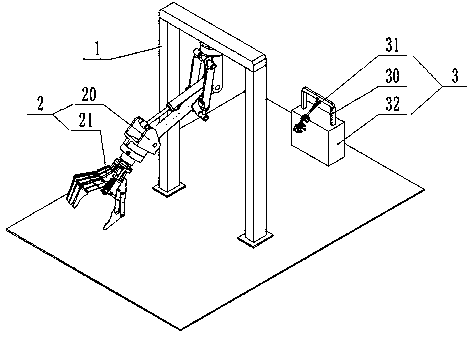

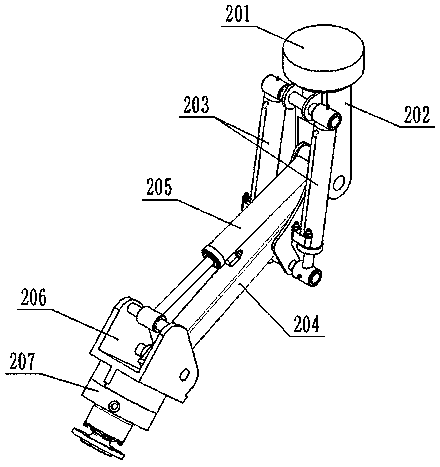

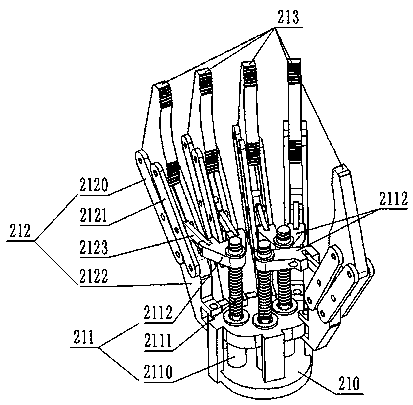

[0026] Such as Figure 1-5As shown, a high-precision quick-response manipulator provided in this embodiment includes a first gantry 1 and a manipulator body 2, and the manipulator body 2 includes a manipulator 20 and a palm 21 connected to the manipulator 20. Said mechanical arm 20 drives said palm 21 to perform rotational movement and swing movement; said palm 21 comprises a link mechanism 212, a linear drive mechanism 211, a connecting seat 210 and a plurality of clamping fingers 213; said connecting seat 210 is connected to said The mechanical arm 20 is connected; a plurality of clamping fingers 213 are respectively connected to the linear drive mechanism 211 through a link mechanism 212; the linear drive mechanism 211 is connected to the connecting seat 210; the linear drive mechanism 211 drives The movement of the link mechanism 212 drives the clamping fingers 213 to open or close.

[0027] In this embodiment, if image 3 As shown, the linear drive mechanism 211 include...

Embodiment 2

[0037] Such as Figure 1-5 As shown, Embodiment 2 is based on Embodiment 1. The high-precision quick-response manipulator also includes a manipulator teaching mechanism 3, and the manipulator teaching mechanism 3 includes a second gantry 30, a wearable manipulator 31 and a control system 32. The wearable manipulator 31 includes a rotary table 310, an arm frame 312, a fixed frame 317 on the back of the hand, a plurality of finger covers 319 and sensors; the sensors include angle sensors and linear displacement sensors, and the angle sensors include the first angle sensor 311 and The second angle sensor 316, the linear displacement sensor includes a first linear displacement sensor 313, a second linear displacement sensor 320 and a third linear displacement sensor 318; the second gantry 30 is installed on the control system 32; The turntable 310 is rotatably connected with the second gantry 30; one end of the arm frame 312 is rotatably connected with the turntable 310, and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com