Clamping force and clamping speed online controllable robot gripper

A robot gripper, gripping speed technology, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problem that the gripping speed cannot be programmed online, does not have force perception, and cannot detect the gripping workpiece, etc. Stable and flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

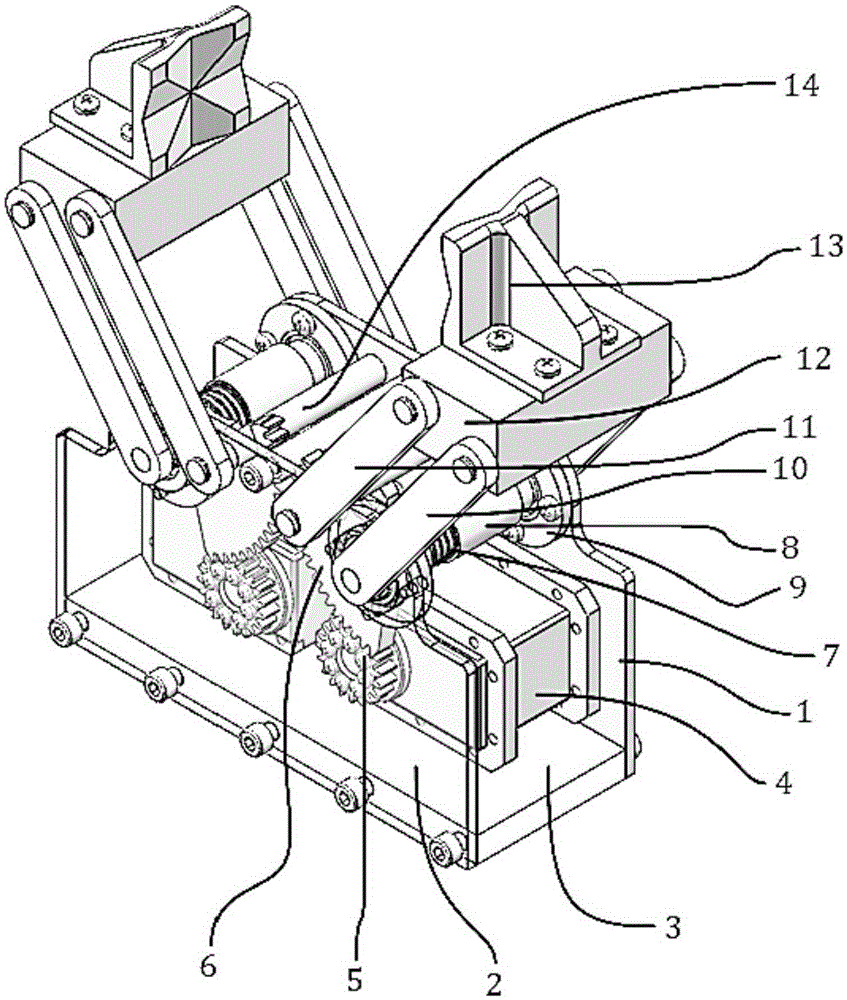

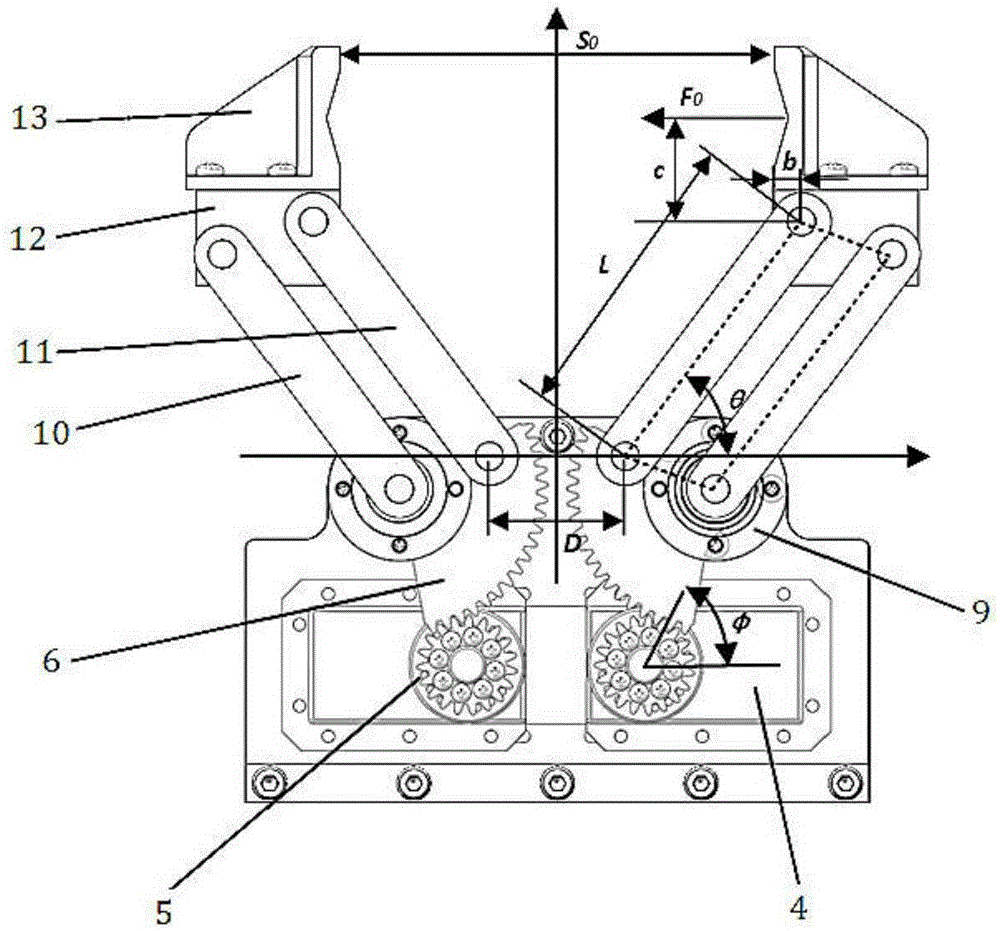

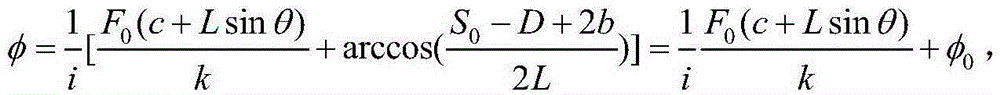

[0025] Such as figure 1 As shown, this embodiment includes: a support structure, fingers 13, steering gear 4 connected in sequence, a gear transmission mechanism, a gear shaft 8, a pair of active connecting rods 10, a horizontal plate 12, a pair of passive connecting rods 11 and a rotating shaft 14 , wherein: the horizontal plate 12 is set horizontally, the finger 13 is vertically set above the horizontal plate 12; the steering gear 4 is symmetrically set in the supporting structure, and the two ends of the gear shaft 8 are respectively connected with a pair of driving connecting rods 10; the rotating shaft 14 is parallel to the gear The shaft 8 is set, and the two ends of the rotating shaft 14 are respectively connected with a pair of passive connecting rods 11; one end of the active connecting rod 10 is connected with the horizontal plate 12, and the other end is connected with the gear shaft 8; one end of the passive connecting rod 11 is connected with the horizontal plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com