Modular optical resonant chamber of high-power laser

A technology of high-power lasers and optical resonators, applied in the field of optical resonators, can solve the problems of unsatisfactory mechanical precision and fundamentally avoiding the stability of optical resonators, and achieve real-time high-precision monitoring and reliable and fast adjustment, high Effect of Precision Optical Axis Monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

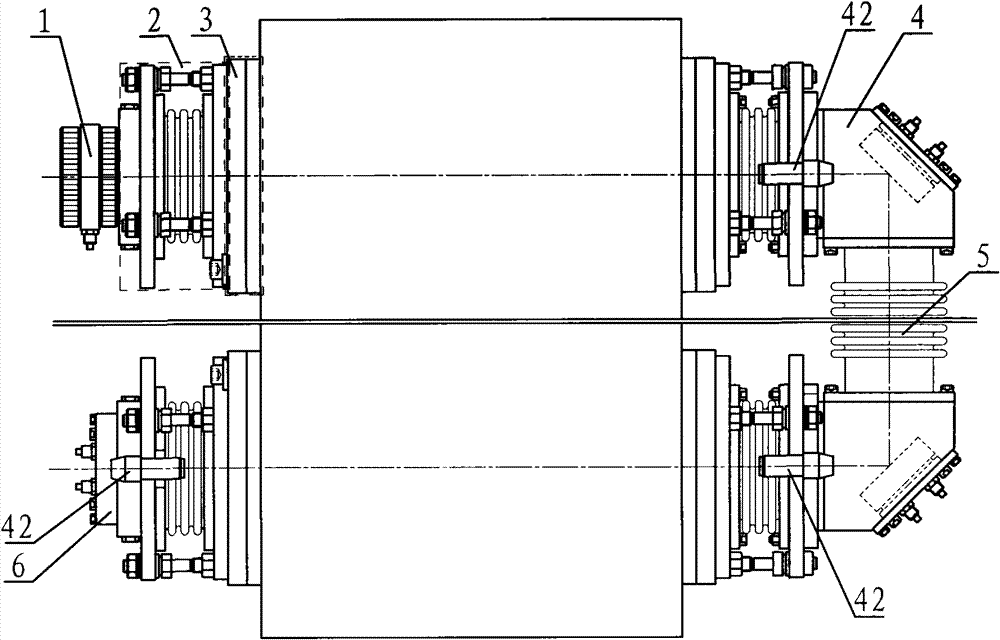

Embodiment

[0026] Embodiment: the present invention comprises a front window mirror module 1, a rear reflector module 6 and a middle folding mirror module 4, and the front window mirror module 1 and the rear reflector module 6 are respectively arranged on the laser through an angle adjustment module 2 and a position adjustment module 3 On one side of the box body 40, the middle folding mirror module 4 is divided into two groups, which are connected by a long bellows assembly 5, and are respectively arranged on the other side of the laser box body 40 through the angle adjustment module 2 and the position adjustment module 3, The rear mirror module 6 and the angle adjustment module 2 of the middle folding mirror module 4 are both provided with an optical axis monitoring module 42 .

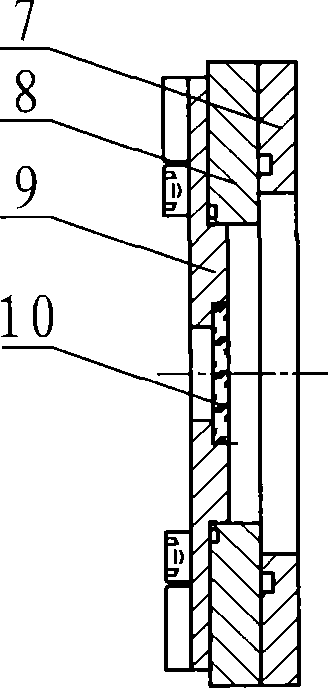

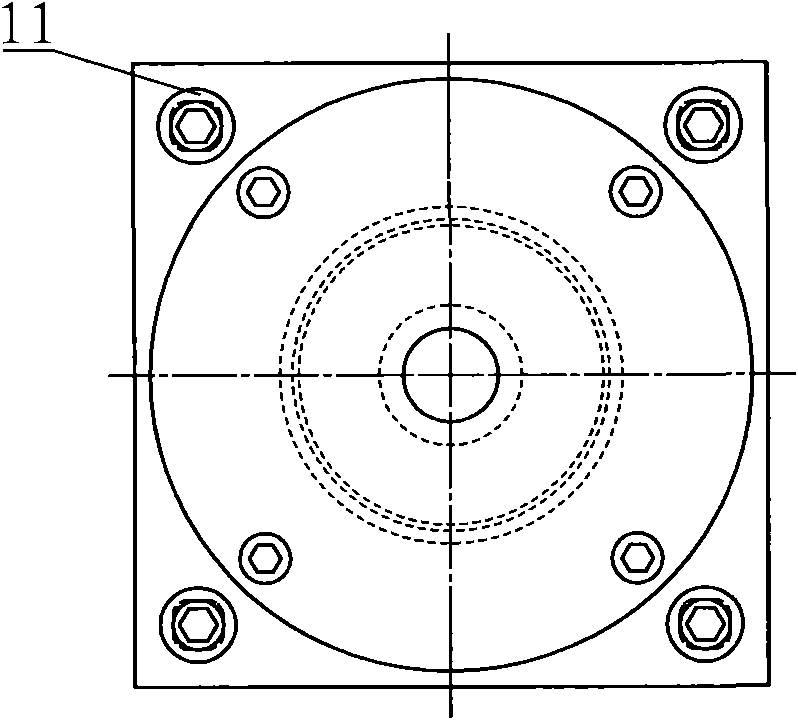

[0027] In this example, the position adjustment module is divided into four groups, and its structure is as follows figure 2 As shown, they all include a sealing flange 7 and an adjustable flange 8 connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com