Multi-joint all-dimensional glove gum dipping device

A kind of dipping device and all-round technology, which is applied in the direction of household components, household appliances, and other household appliances, etc. It can solve the problems of manufacturer loss, slow running speed of actuating parts, rigid dipping angle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

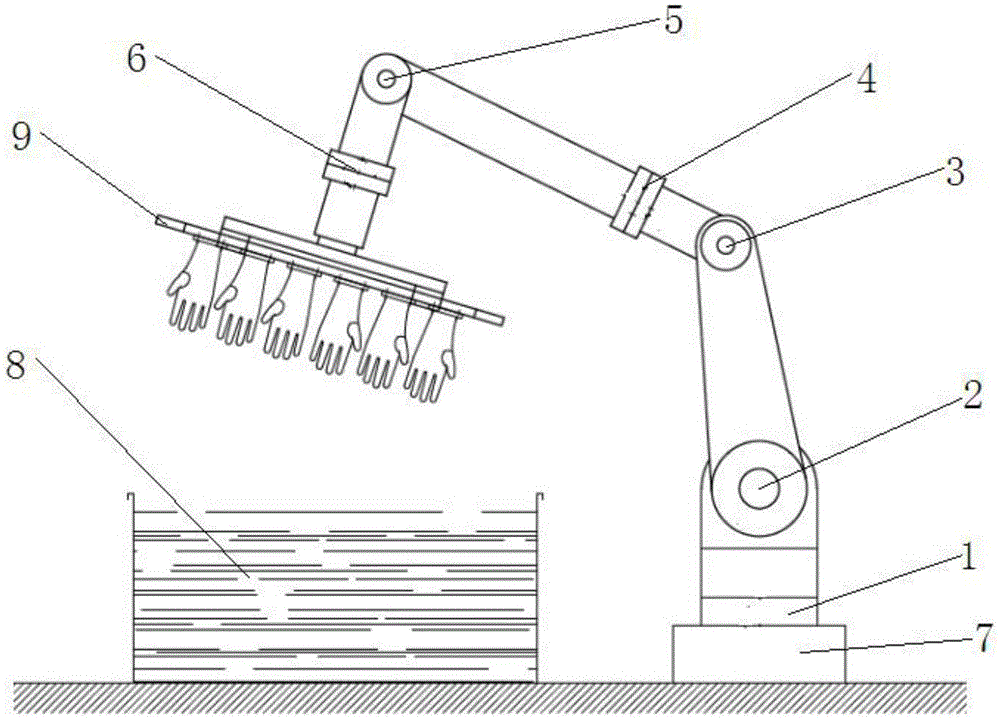

[0014] refer to figure 1 As shown, a multi-joint all-round glove dipping device includes a base 7 fixed on the ground, the base 7 is connected to the first crossbeam 10 through the first joint 1, and the first crossbeam 10 is connected through the second joint 2 The second beam 11, the second beam 11 is connected to the third beam 12 through the third joint 3, the third beam 12 is connected to the fourth beam 13 through the fourth joint 4, and the fourth beam 13 is connected to the fifth joint 5 The fifth crossbeam 14 is connected, the fifth crossbeam 14 is connected to the sixth crossbeam 15 through the sixth joint 6, the sixth crossbeam 15 is connected to the glove mold 9, and the dipping pool 8 is arranged below the glove mold 9.

[0015] The first joint 1 , the second joint 2 , the third joint 3 , the fourth joint 4 , the fifth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com