Polishing and grinding device with six-freedom-degree mechanical arms

A polishing and grinding, manipulator technology, used in grinding/polishing equipment, metal processing equipment, grinding/polishing safety devices, etc., can solve the problems of low workpiece consistency, high labor dependence, low processing efficiency, etc., to save effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

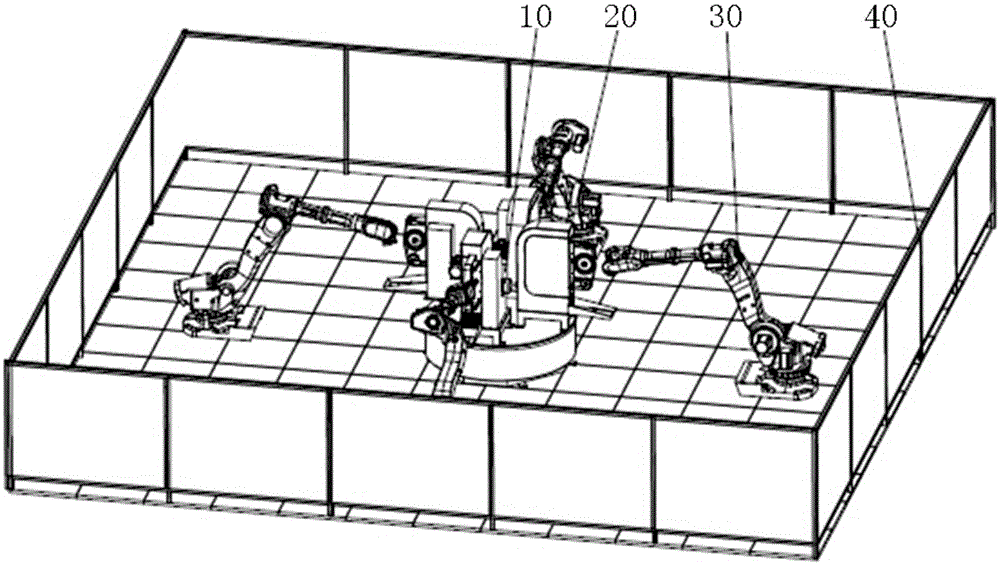

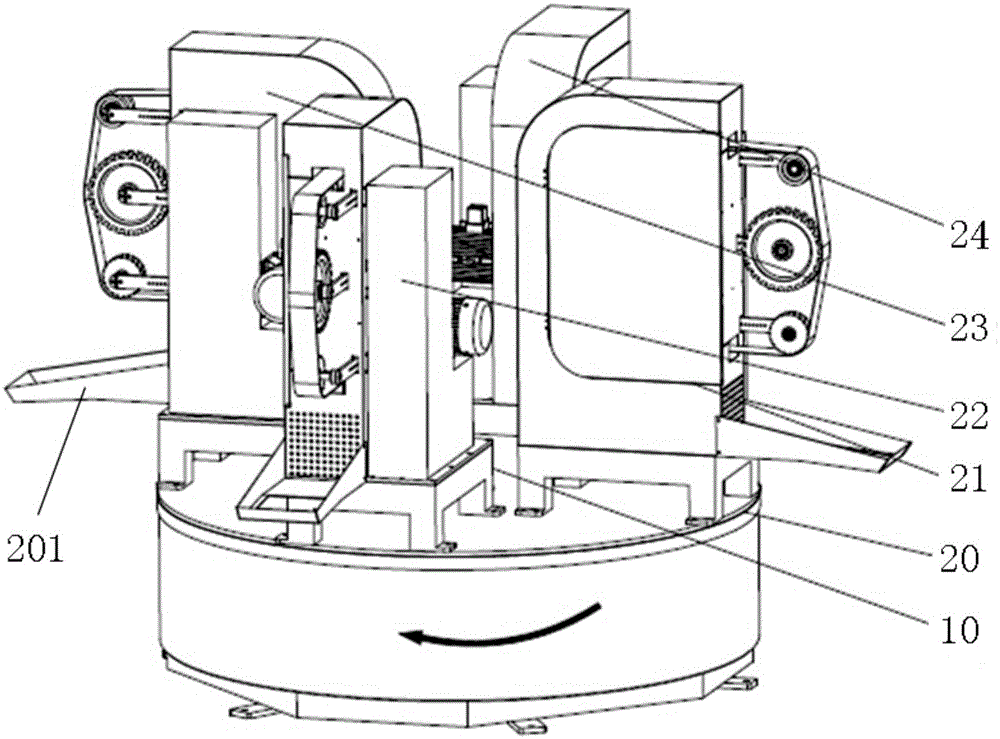

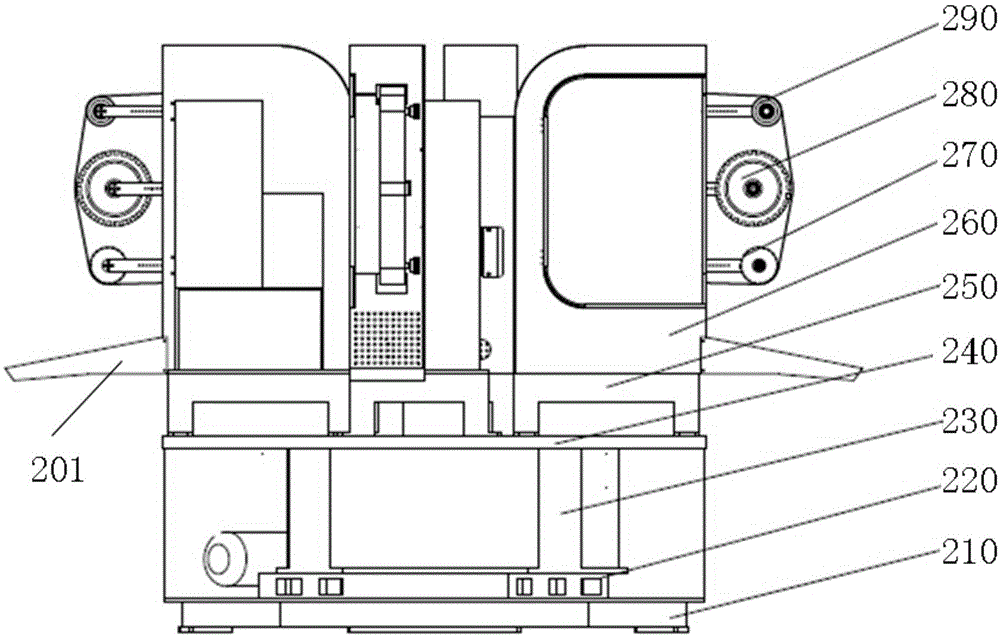

[0018] refer to figure 1 , the present invention provides a six-degree-of-freedom manipulator polishing and polishing equipment, which includes a control system (not shown), and an indexing disc polishing workstation 20 connected to the control system, an electric ring part 10, and a plurality of six-degree-of-freedom manipulators 30. The electric ring part 10 is arranged at the center of the indexing disc grinding workstation 20, the indexing disc grinding workstation 20 is evenly distributed on the disc 240, and the six-degree-of-freedom manipulator 30 is evenly distributed on the periphery of the indexing disc grinding workstation 20, The indexing disk grinding workstation 20 is electrically connected to the control system through the electric ring part 10 . The combination of multiple six-degree-of-freedom industrial manipulators and the ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com