Step-by-step type electrochemical polishing device

A polishing device and electrochemical technology, applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems of low processing efficiency, inability to polish and level small workpieces, high cost, etc., and achieve simple structure, convenient industrial production, The effect of high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

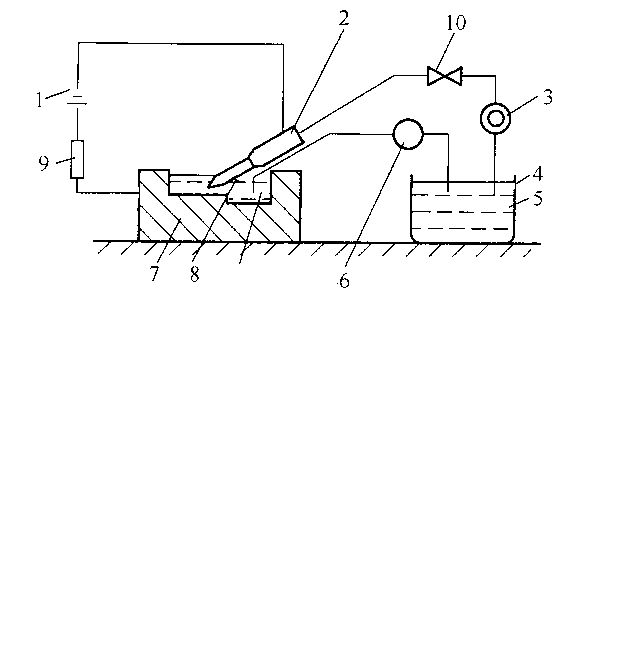

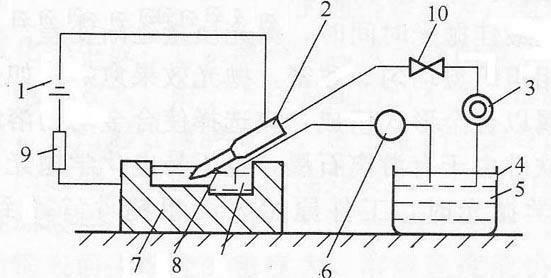

[0011] Below in conjunction with accompanying drawing, further illustrate the present invention.

[0012] Such as figure 1 As shown, a step-by-step electrochemical polishing device of the present invention, wherein the positive pole of the power supply 1 is connected to the workpiece 7, and the negative pole of the power supply 1 is connected to the electric polishing machine 2. In order to effectively control the current, the power supply 1 and the An adjustable resistance 9 is also provided between the workpieces 7; the electric polisher 2 is connected with the pump 3, and in order to effectively control the electric polisher 2, a valve 10 is also provided between the electric polisher 2 and the pump 3; Electrolyte 5 is housed in the workpiece 7, and one end of the attractor 6 is immersed in the electrolyte 5 of the workpiece 7, and the other end is immersed in the electrolyte 5 of the electrolytic tank 4. In order to increase the corrosion resistance of the electrolytic tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com