Mechanical arm positioning fetching method based on machine vision

A technology of machine vision and robotic arm, applied in the field of robotic arm, can solve the problems of high cost and poor real-time performance, and achieve the effect of improving accuracy, fast and flexible grasping, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

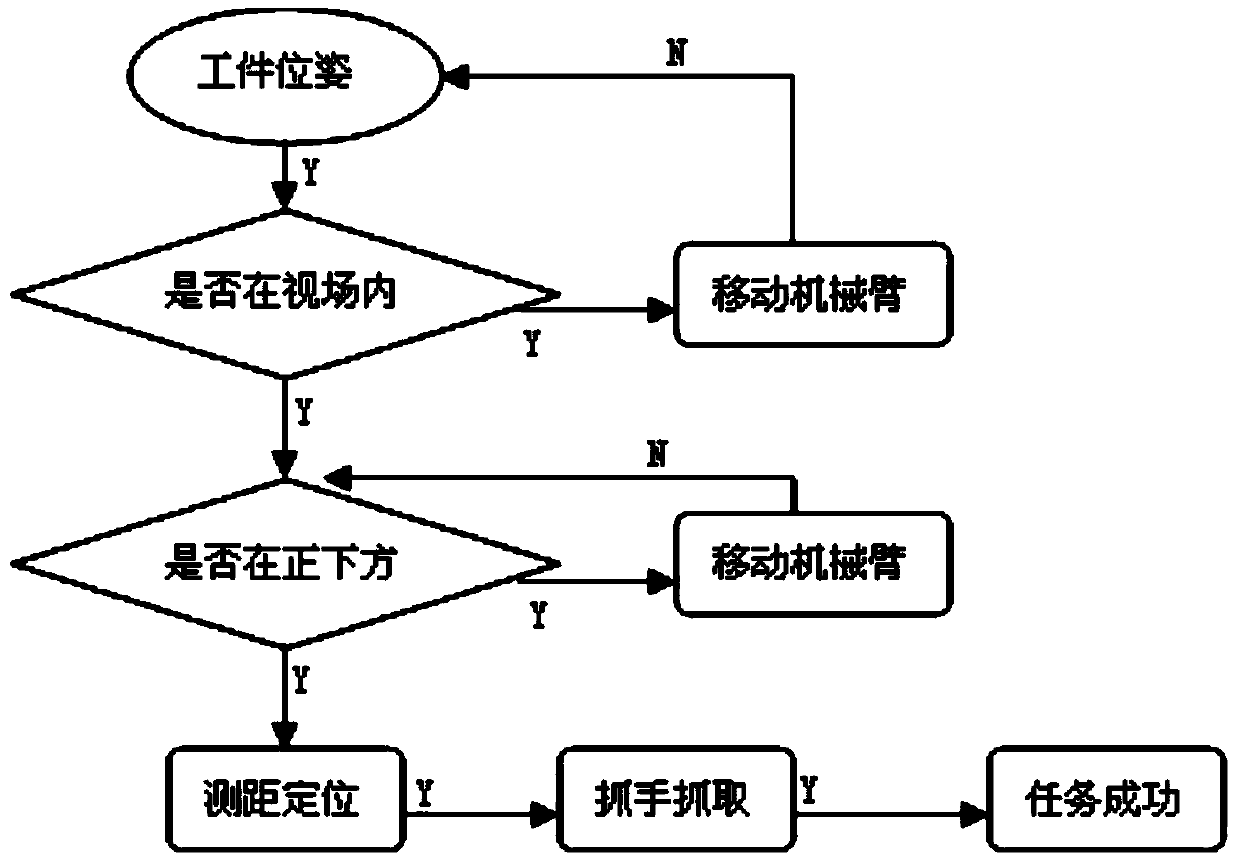

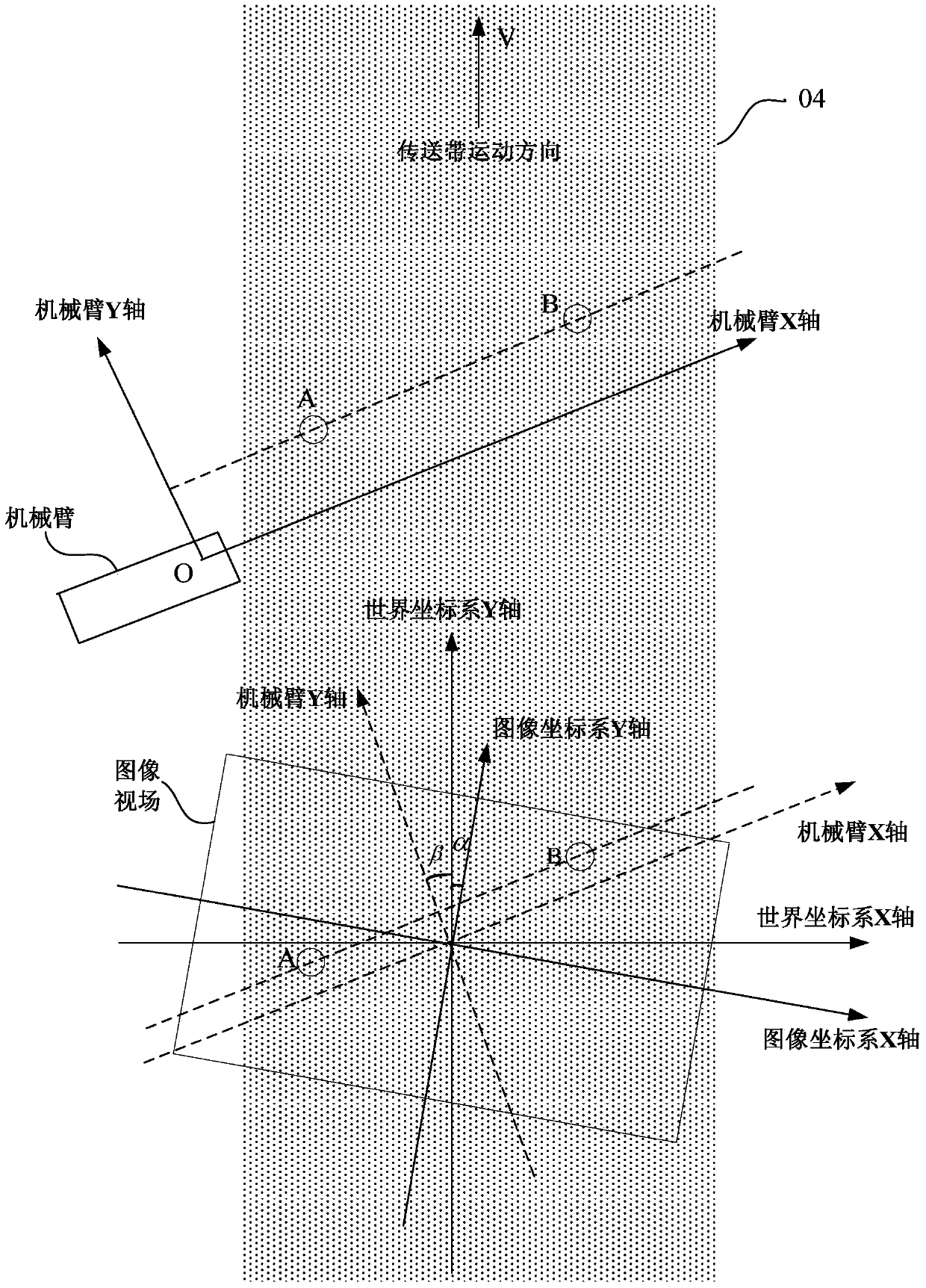

[0050] The above and other technical features and advantages of the present invention will be further described below in conjunction with the accompanying drawings.

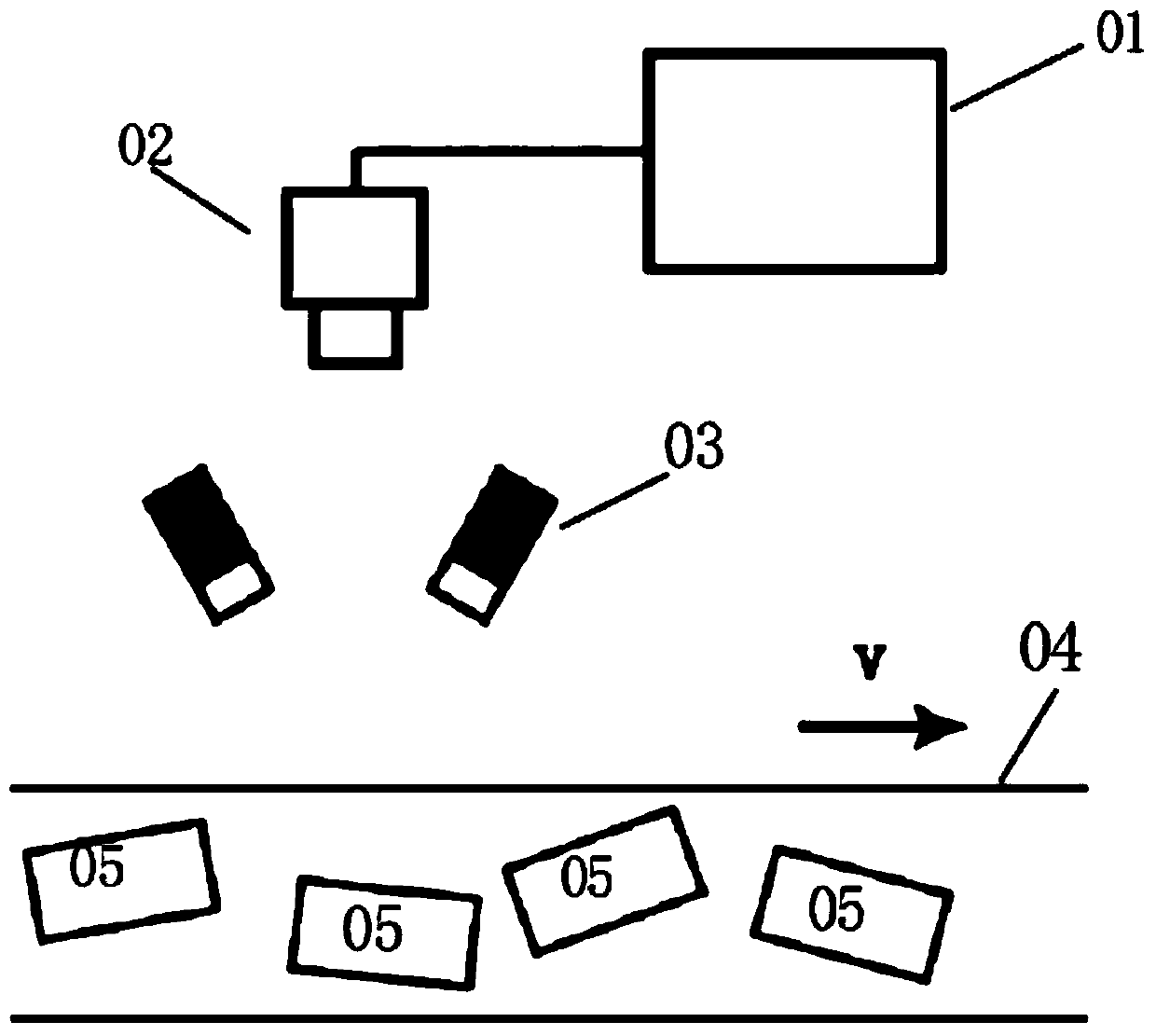

[0051] see figure 2 , is a schematic diagram of the position among the camera 02 , the conveyor belt 04 and the workpiece 05 in the present invention. The present invention connects the camera 02 and the mechanical arm (not shown in the figure) through the computer 01 to carry out information transmission and control. The present invention may include a plurality of mechanical arms, which are arranged beside the conveyor belt at certain intervals, and grasp the workpieces 05 scattered on the conveyor belt 04 under the control of the computer 01 . One of the advantages of the present invention is that only one camera 02 needs to be installed above the conveyor belt 04 , instead of having to equip each mechanical arm with a camera as in the prior art, which greatly reduces the production cost and facilitates larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com