Multifunctional soft granule making machine set

A soft granule and multi-functional technology, applied in food science, animal feed, food forming, etc., can solve the problems of increasing labor intensity of workers, large floor area, large investment in equipment, etc., to reduce handling links and reduce land occupation area, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in more detail below in conjunction with examples.

[0027] Best practice:

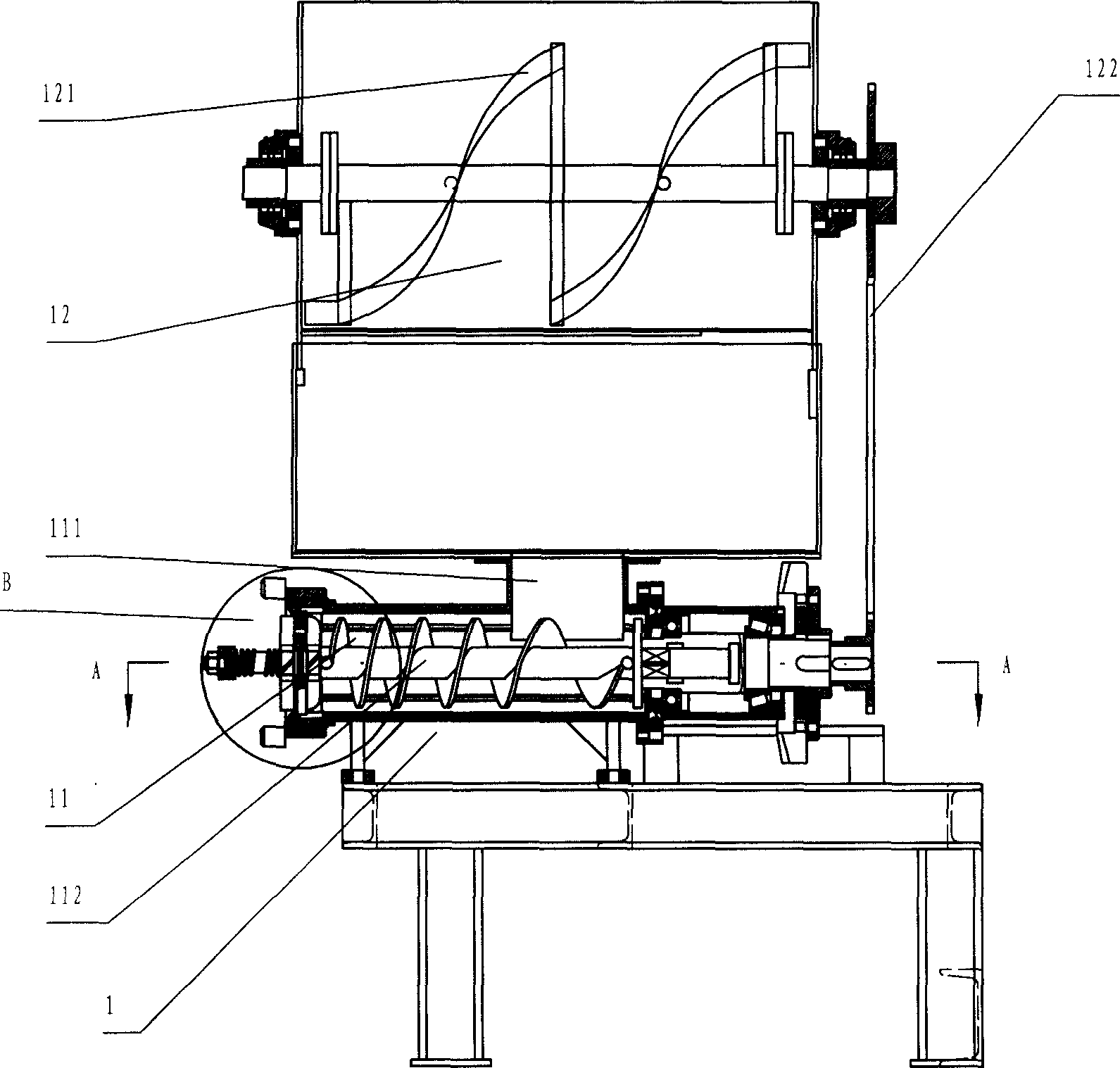

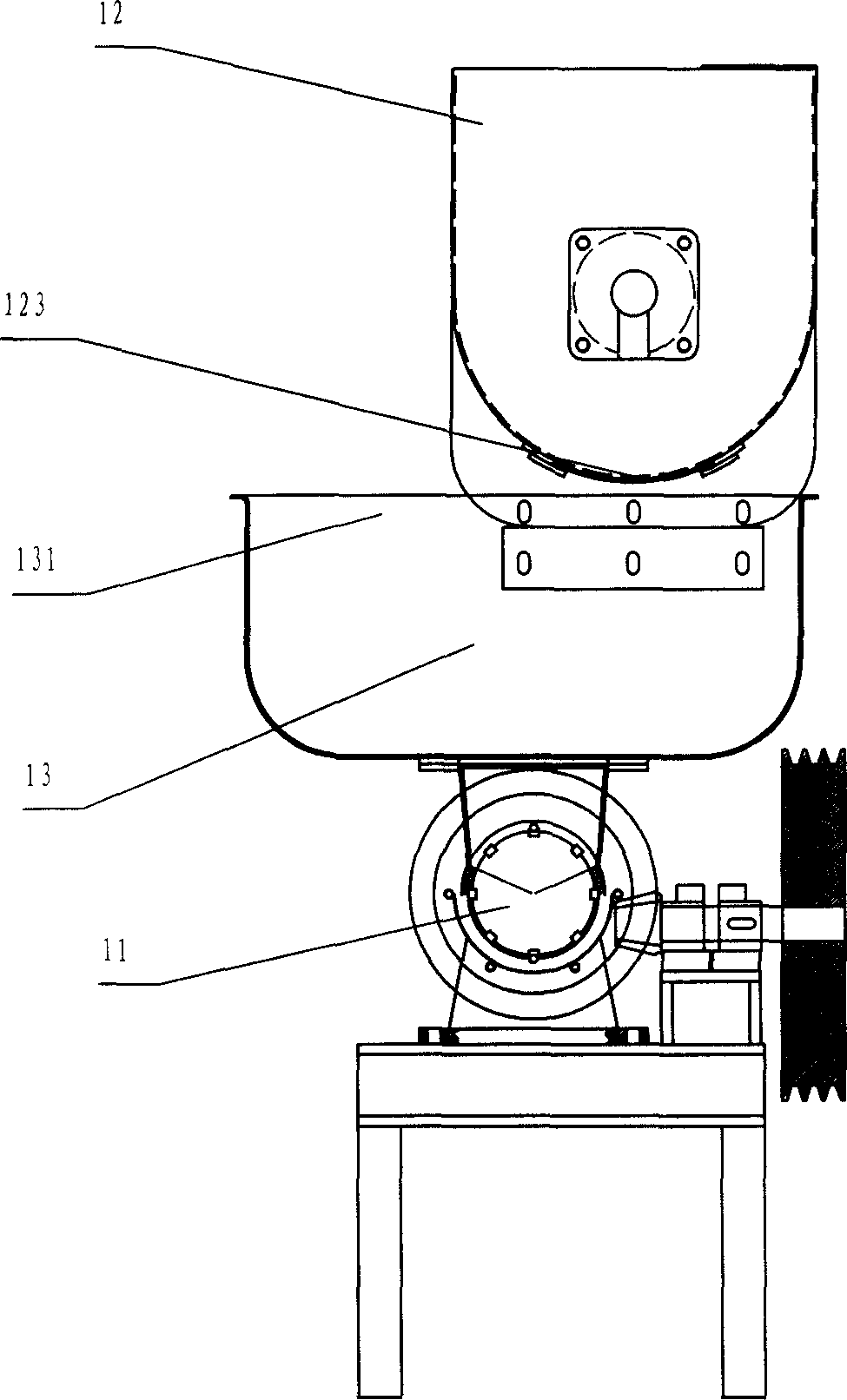

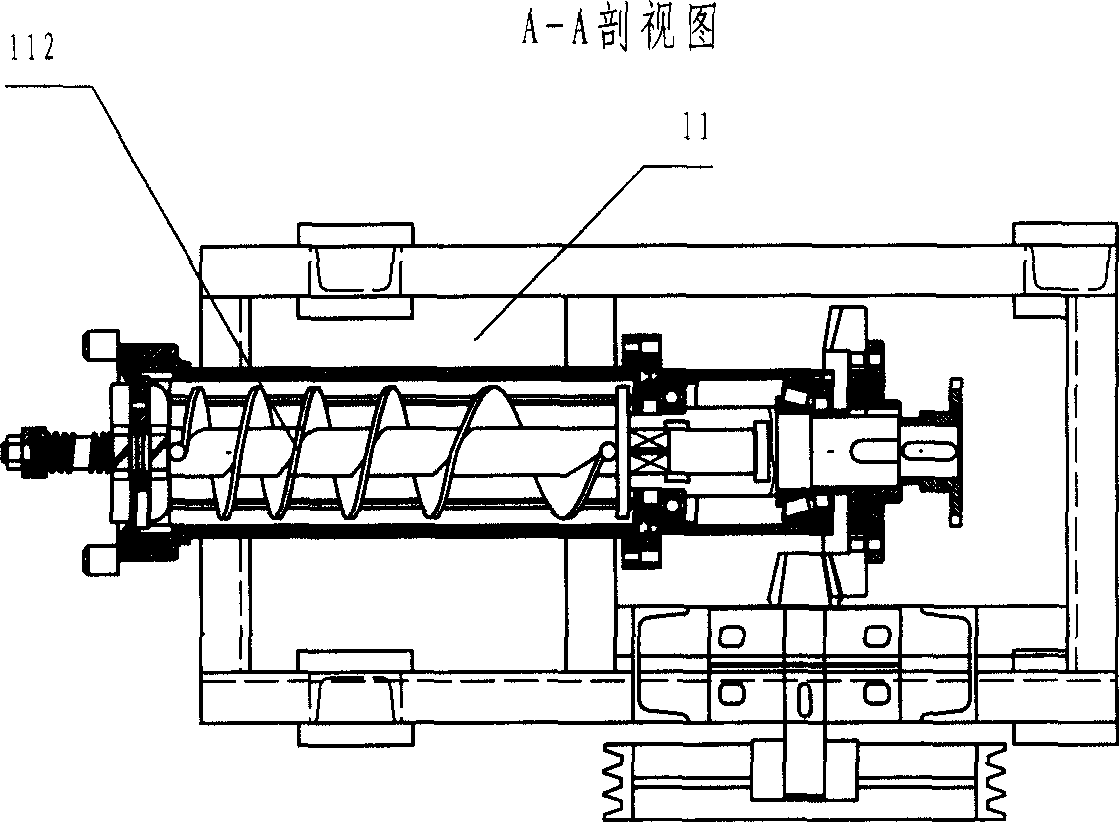

[0028] a kind of like figure 1 , 2 And the multifunctional soft granule unit shown in 3, it comprises granulator 1. The granulator 1 includes an extrusion cylinder 11 and a mixing bin 12 for the mixer. The mixing bin 12 is connected with the extruding barrel 11 of the granulator. The delivery connection between the mixing chamber 12 and the extruding cylinder 11 is realized by setting a buffer chamber 13 between them. The buffer chamber 13 is an open box-shaped body, and the opening end of the buffer chamber 13 is Next to the mixing bin 12, the material inlet 111 of the extruding barrel is provided at the bottom of the box-shaped buffer bin, and the material inlet 111 is staggered with the discharge port 123 of the mixing bin. The mixing bin 12 and the extruding barrel 11 share the same power, and the diesel engine drives the screw 112 in the extrusi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com