Tea leaf drying and screening device for tea leaf processing plants

A technology for screening devices and processing plants, which is applied in the direction of tea processing before extraction, etc., can solve the problems of not meeting the production needs of tea processing plants, low production efficiency, and affecting processing efficiency, so as to save handling links, high production efficiency, and avoid pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

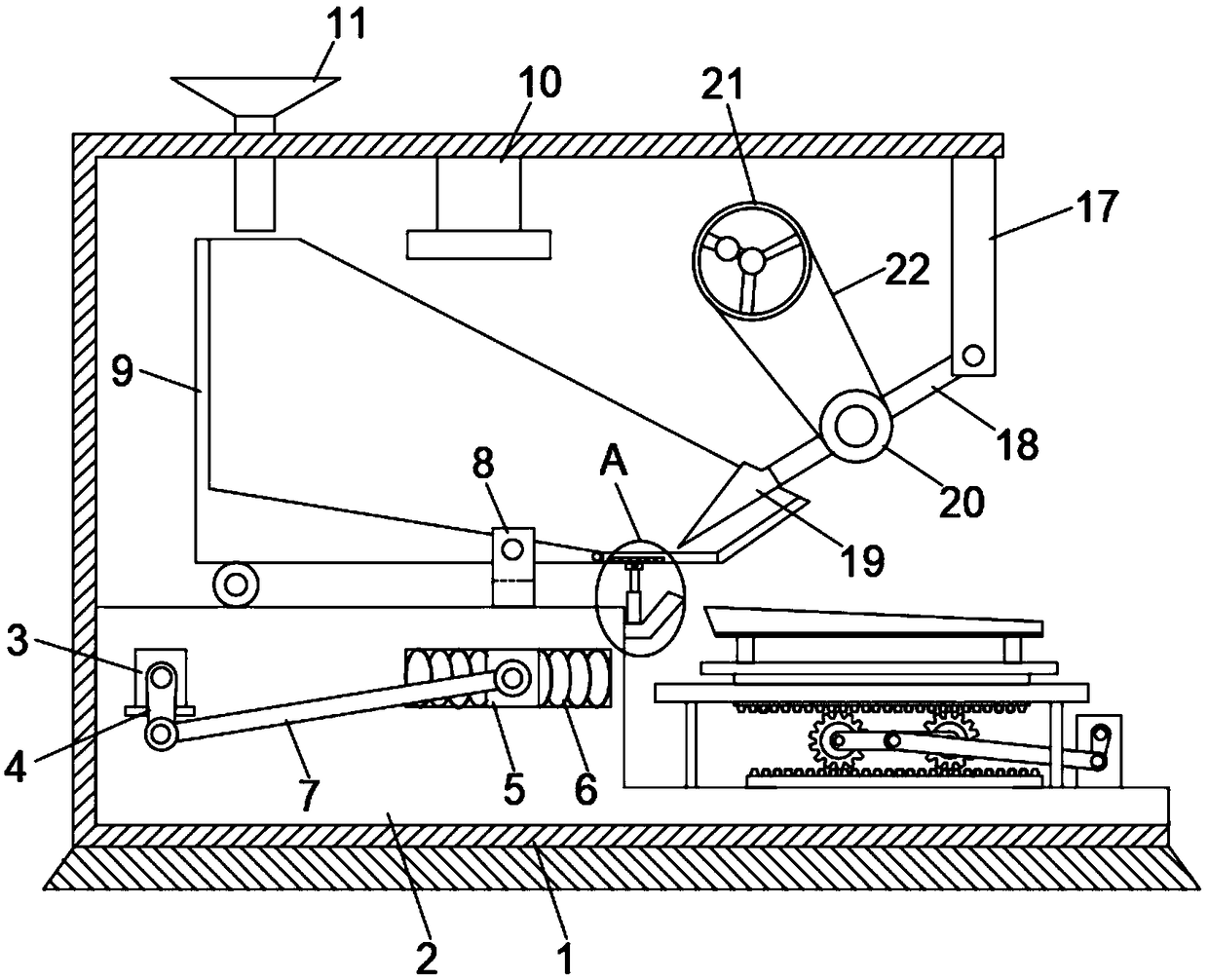

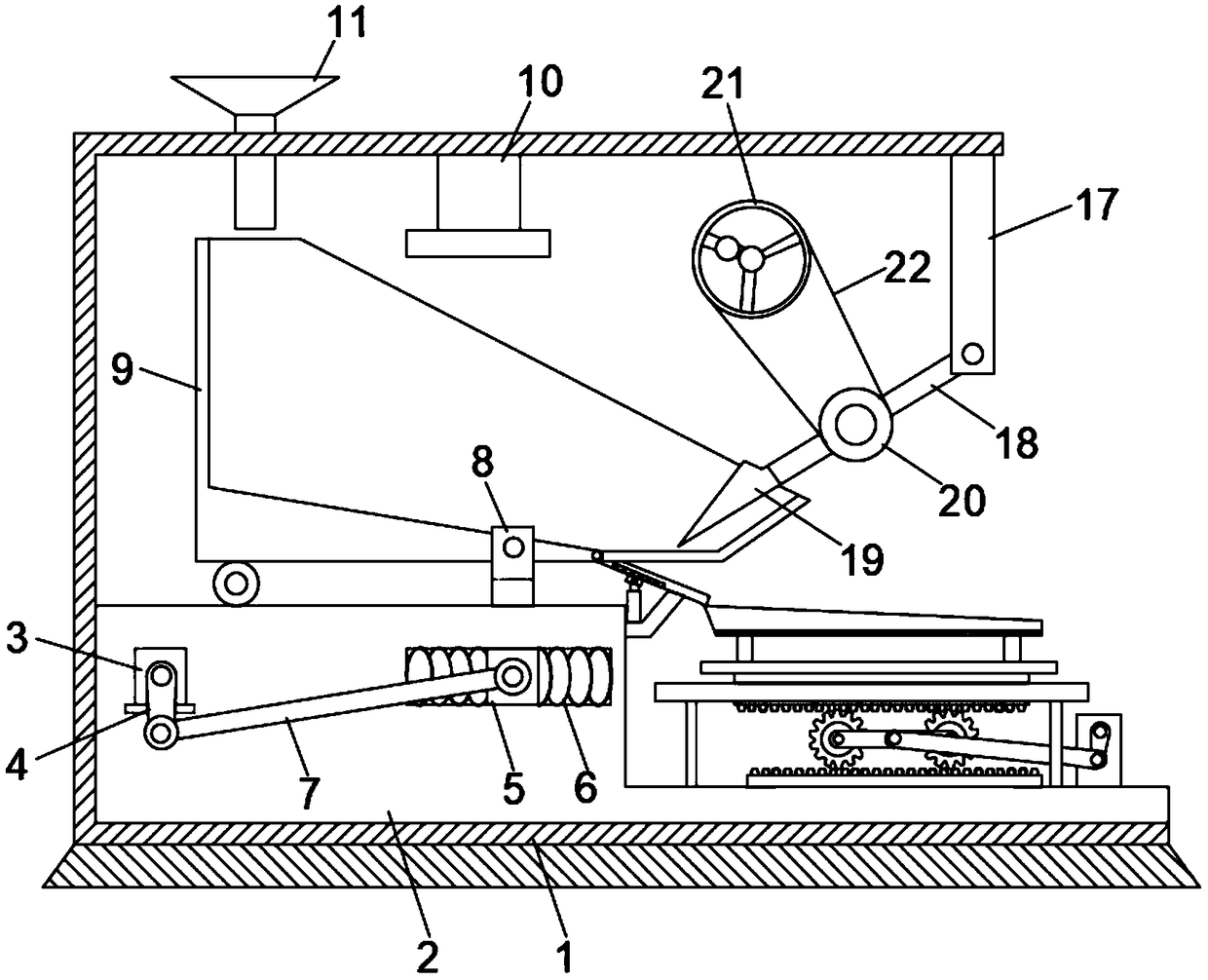

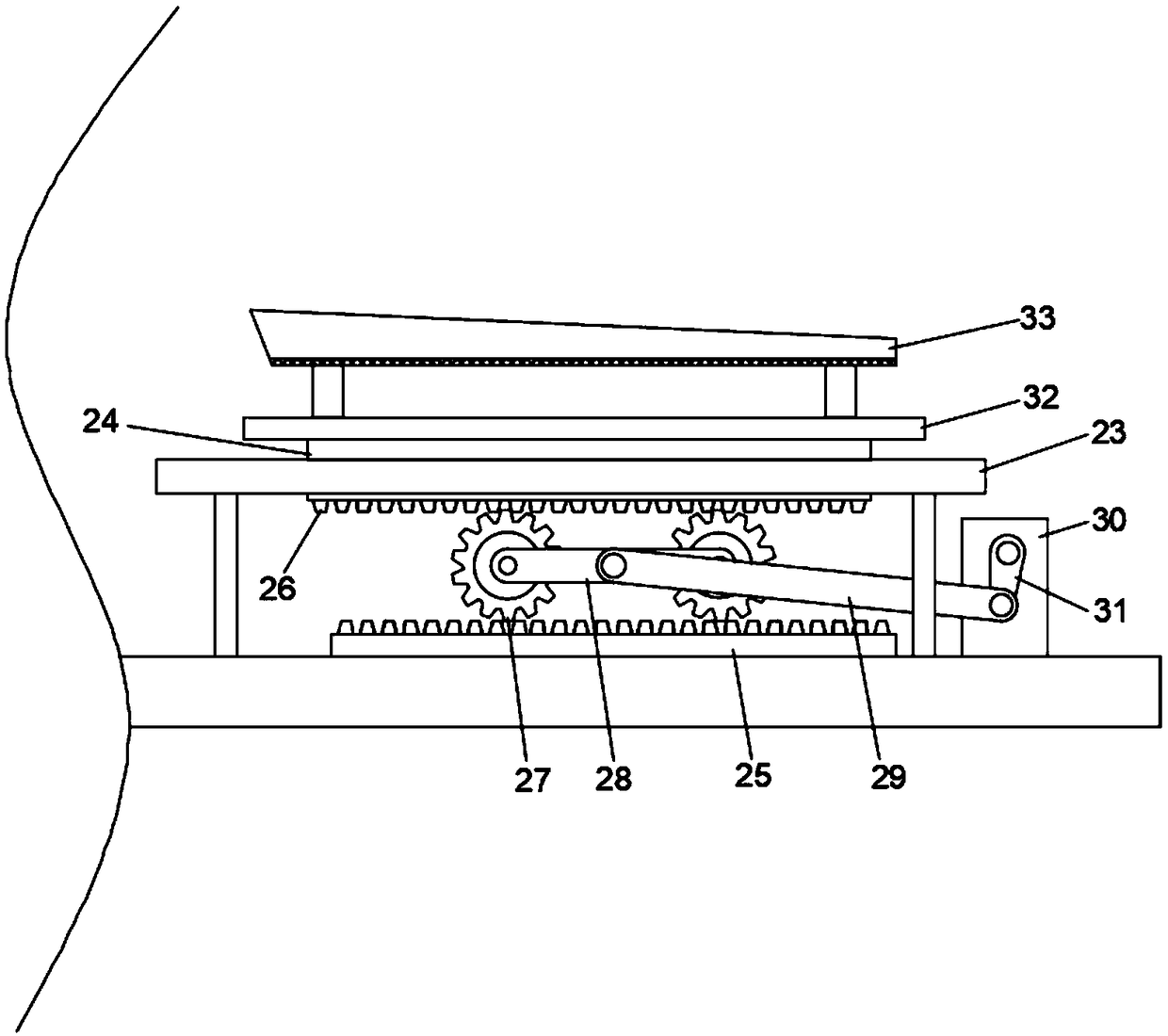

[0020] refer to Figure 1-5 , a tea drying and screening device used in a tea processing factory, comprising a box body 1, an opening is opened at the right end of the box body 1, a table body 2 is fixedly installed at the inner bottom of the box body 1, and a support frame is connected to the side wall of the table body 2, The upper end of the support frame is fixedly equipped with a first motor 3, the first motor 3 adopts a servo motor, and the sliding speed of the drying car 9 is controlled by controlling the rotating speed of the first motor 3, and the bottom of the support frame and the side wall of the table body 2 are fixedly welded The reinforcing ribs arranged obliquely make the supporting frame more stable to the supporting structure of the first motor 3, the first rotating handle 4 is sleeved on the output rod of the first motor 3, and the inside of the table body 2 is also provided with an installation cavity, the installation cavity The inside of the body is slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com