Turning, sewing, unwinding and rolling integrated device

A technology of unwinding and seaming, which is applied in the direction of winding strips, transportation and packaging, thin material processing, etc., and can solve problems such as the decline in work efficiency, the quality of seam heads, the impact on product work efficiency, and the decline in staff physical strength. The handling link, low labor cost, and the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

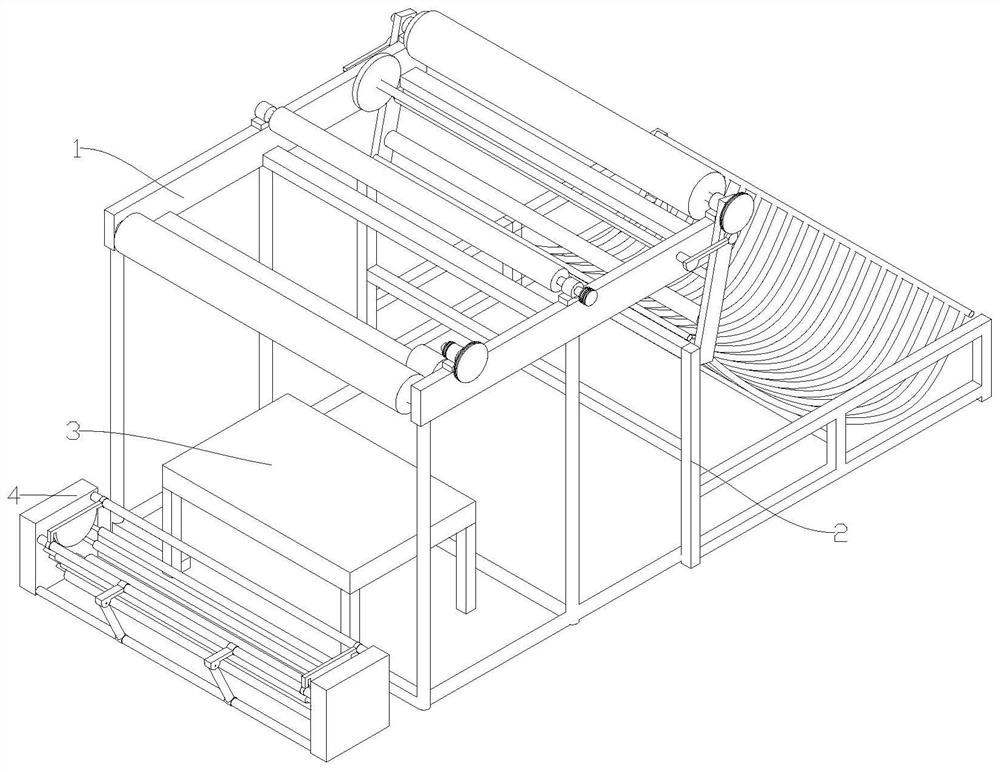

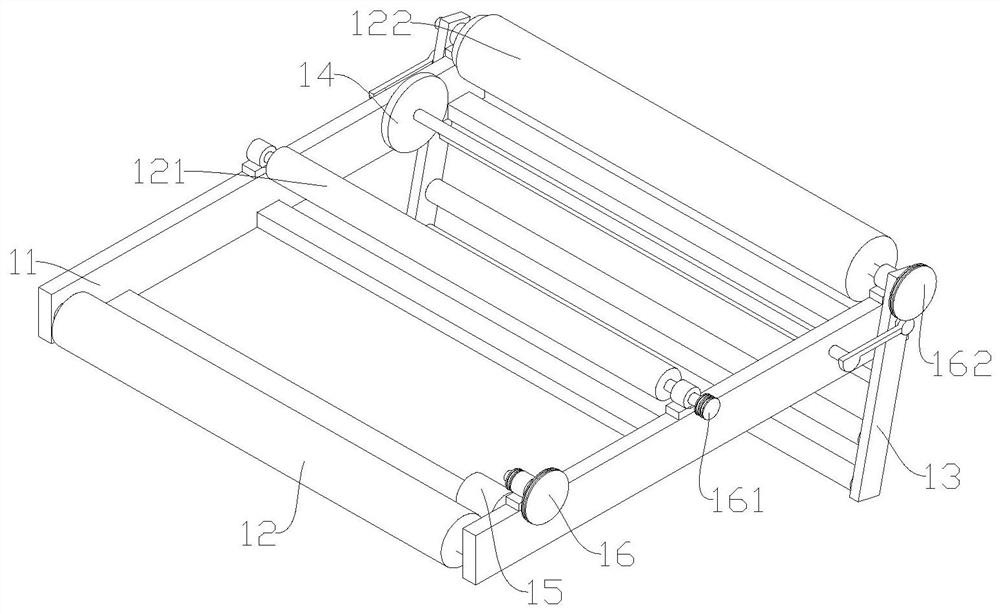

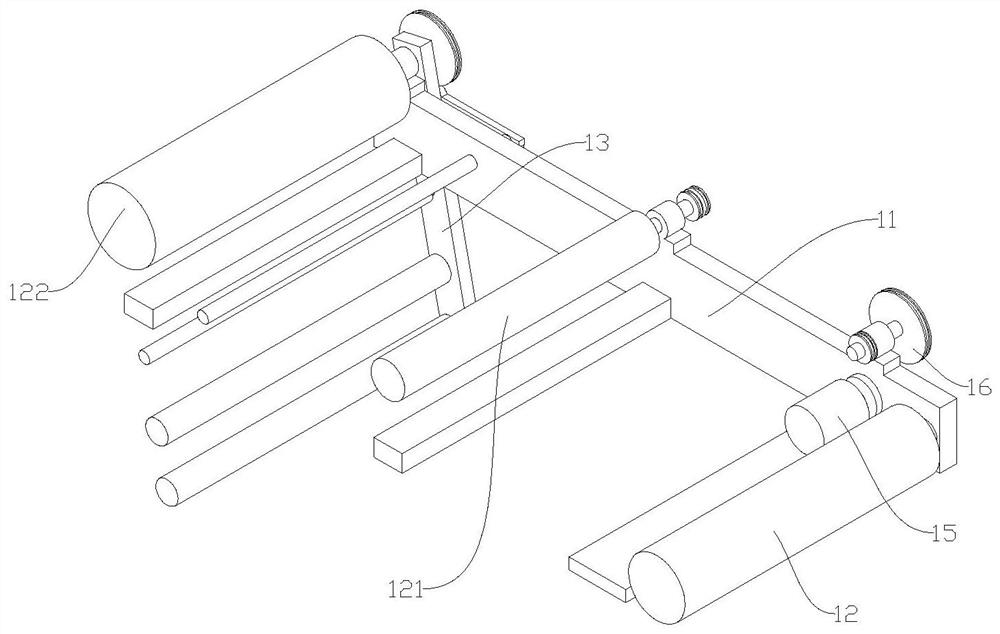

[0034] Example. An integrated device for turning seam, unwinding and rolling, which is composed of Figures 1 to 7 As shown, it includes an unwinding mechanism 1 and a seam turning mechanism 3 located below the unwinding mechanism 1; the rear of the unwinding mechanism 1 is connected with a fabric supporting mechanism 2 and a rolling mechanism in sequence; the front of the unwinding mechanism 1 is provided with Material preparation mechanism 4; the end of the unwinding mechanism 1 is provided with an elastic mechanism 13; the bottom of the unwinding mechanism 1 is connected with the bottom of the turning mechanism 3 through a connecting piece.

[0035] The seam turning mechanism 3 is a sewing device.

[0036] The unwinding mechanism 1 includes an unwinding frame 11 , a No. 1 roller 12 , a No. 2 ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com