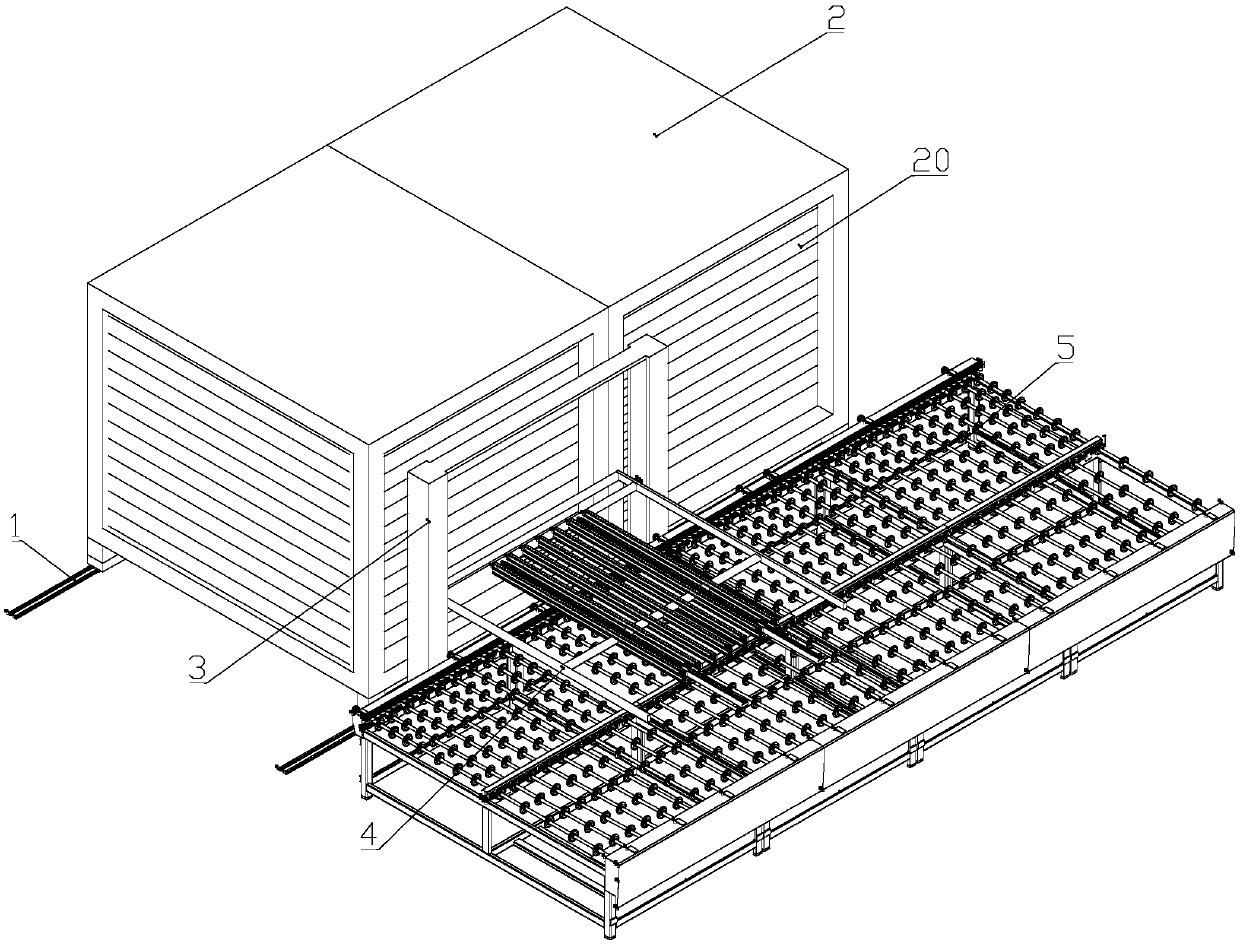

Glass warehousing system and control method

A storage system and glass technology, applied in the direction of conveyor objects, furnaces, storage devices, etc., can solve the problems of glass access, classification difficulties, lower work efficiency, large space occupation, etc., reduce intermediate logistics handling links, and simple structure , the effect of shortening the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

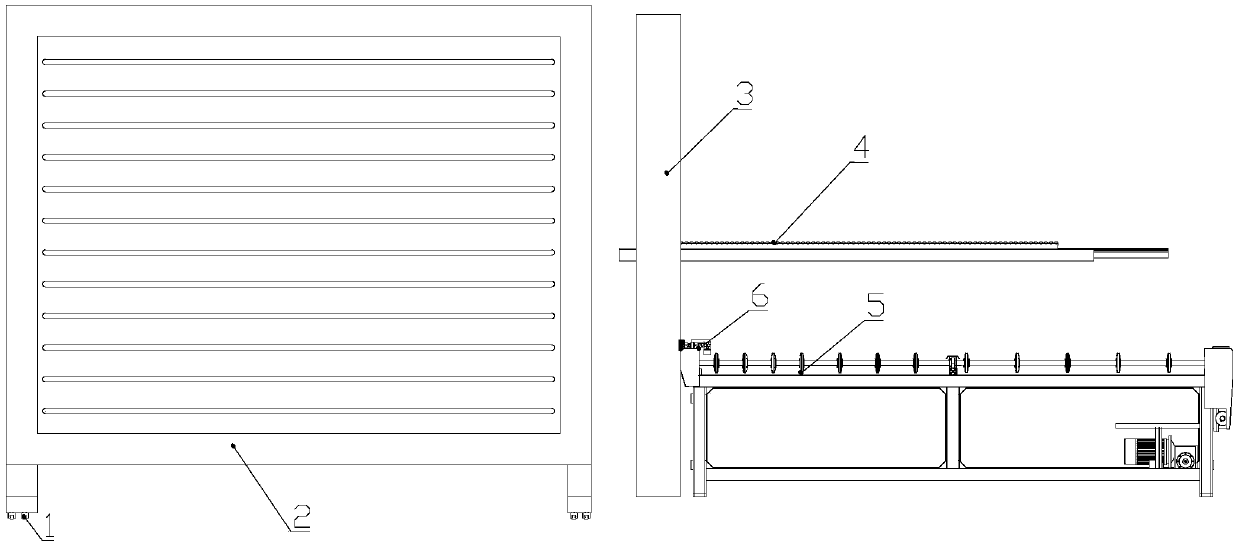

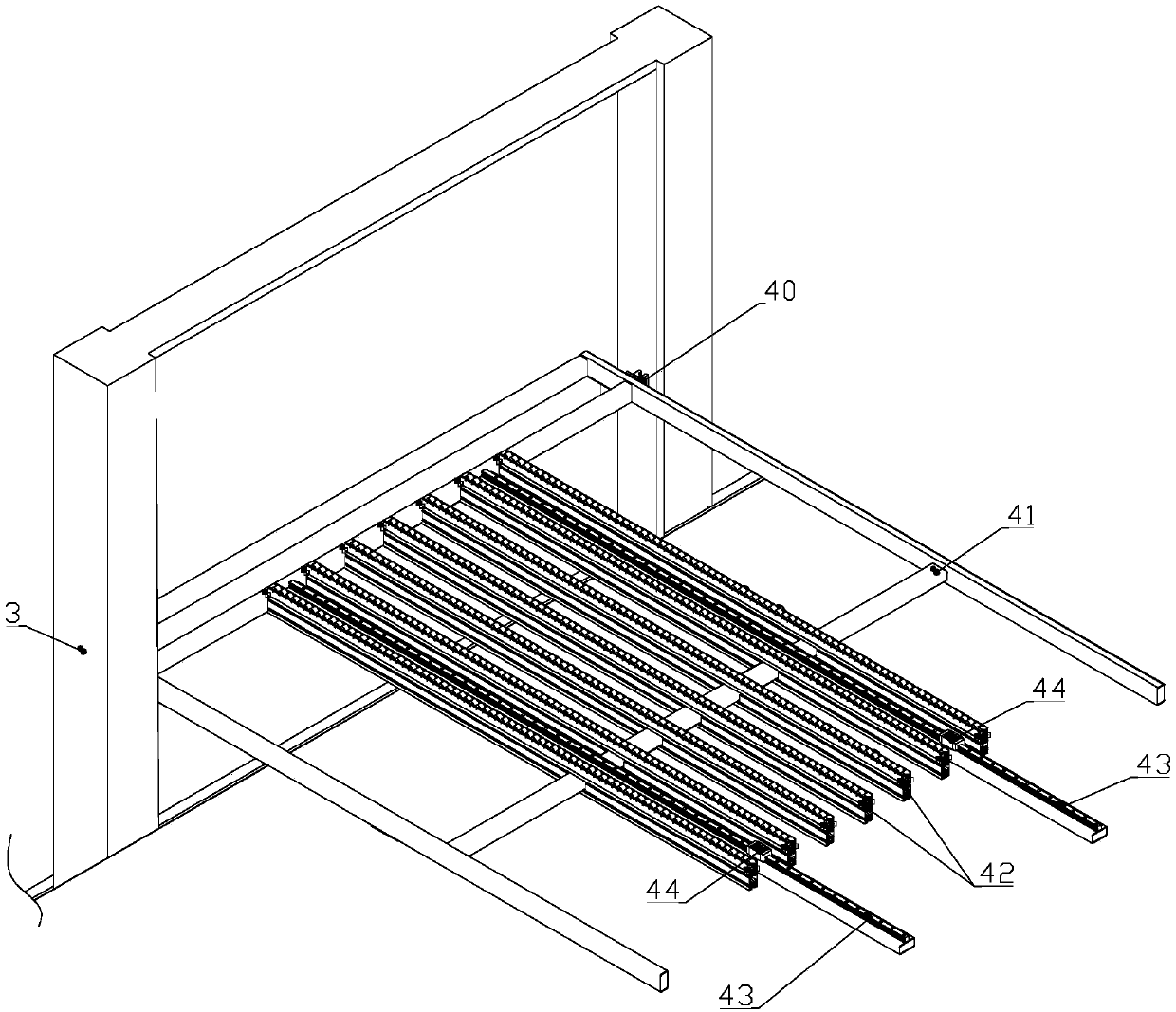

Method used

Image

Examples

specific Embodiment 1

[0049] Specific embodiment 1, according to the customer's order requirements, if the original glass of 3660mm*2440mm or 6330mm*3360mm needs to be reasonably filled with the order glass, so the glass sheets obtained by cutting personnel according to the order are of different sizes, and the glass sheets that enter the storage system Glass is also free access to complete customer orders through the following control methods:

[0050] (1) In the cutting process, the first glass sheet is transported to the delivery platform 5, and the specifications and other information of the first glass sheet are input into the storage management control system, and the storage management control system calculates the storage of the first glass sheet in the storage cabinet 2 position, and control the glass fetching mechanism 4 to send the first glass sheet into the predetermined storage position to complete the storage action;

[0051] (2) Before the storage operation of the first glass piece i...

specific Embodiment 2

[0054] Specific embodiment 2: when the edging process is busy, the storage management control system intelligently controls, automatically stores the specifications of the glass sheet and calculates the storage position of the glass sheet in the storage cabinet 2, and controls the glass pick-up mechanism 4 to send the glass sheet into a predetermined location The storage position completes the storage action, and all the glass sheets entering the transfer platform 5 are stored in the grid corresponding to the storage cabinet 2. When the edging process is idle, the storage management control system intelligently controls the glass pick-up and delivery mechanism 4, and transfers the glass from the storage cabinet 2. According to the size of the glass sheets from small to large, the glass sheets are reversely conveyed and taken out, and the glass sheets in the storage cabinet 2 are automatically compensated from small to large and enter the double-sided machine for edge grinding. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com