Method and equipment for continuous production of stewed food

A food and equipment technology, applied in the field of food production equipment, can solve the problems of complex vacuum packaging machines, high labor intensity, uneven temperature, etc., and achieve the effect of reducing handling links, reducing labor intensity, and high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below by specific embodiment the present invention is described in detail as follows:

[0034] This method of continuous production of marinated food includes thawing, pickling, marinating, cooling, small packaging, sterilization, cleaning, drying, large packaging and storage in sequence. conduct.

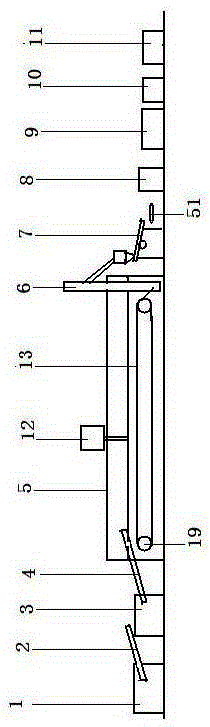

[0035] exist figure 1 Middle: The equipment for the continuous production of stewed food includes thawing tank 1, first conveyor belt 2, pickling tank 3, second conveyor belt 4, marinating tank 5, bucket elevator 6, cooling vibrating screen 7, air pressure packaging Machine 8, sterilizing equipment 9, spiral cleaning machine 10, dryer 11, brine pot 12 is arranged beside the brine tank 5, stainless steel wire mesh conveyor belt 13 is arranged in the brine tank 5, and the above-mentioned equipment forms a continuous production line of brine .

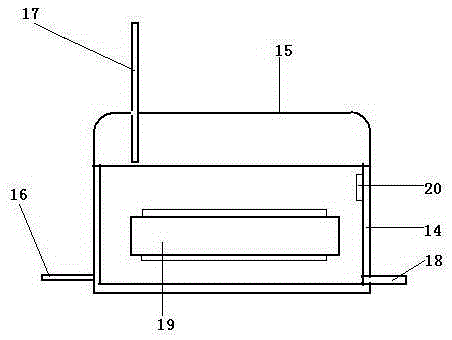

[0036] exist figure 2 Middle: the stewed tank 5 is 20 meters long, the cross section is rectangular, the two sides and the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com