Synchronous assembly tool used for seat backrest and seat foam

A seat back and assembly tooling technology, which is applied to vehicle seats, transportation and packaging, and special positions of vehicles, etc., can solve the problems of affecting work efficiency and production costs, affecting the production efficiency of car seats, and occupying a large space. Achieve the effects of reducing storage and handling links, simple structure, and saving equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

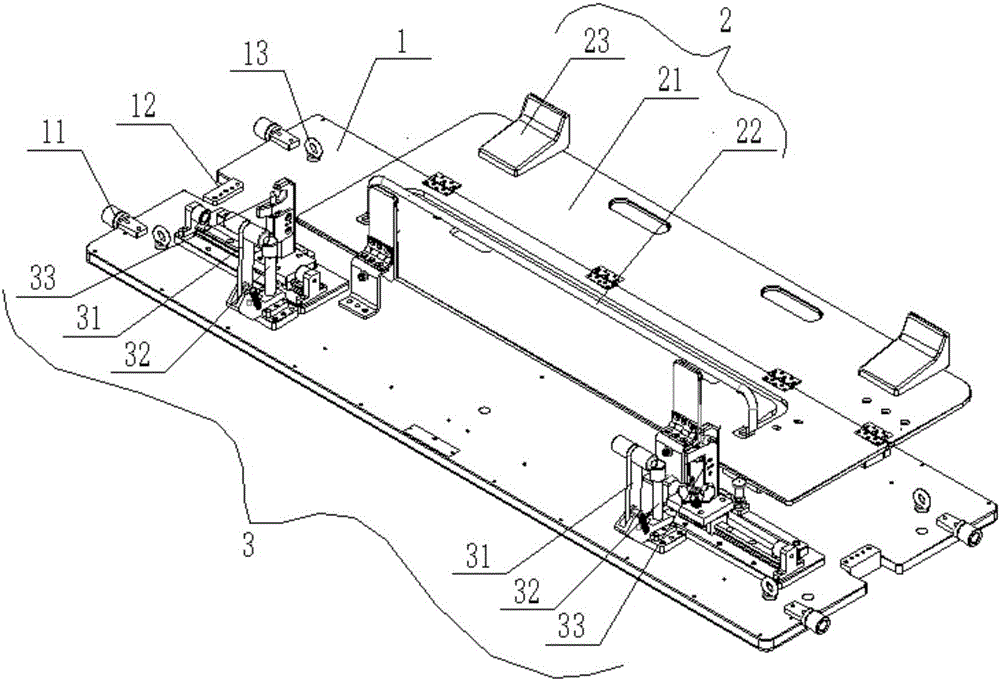

[0026] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

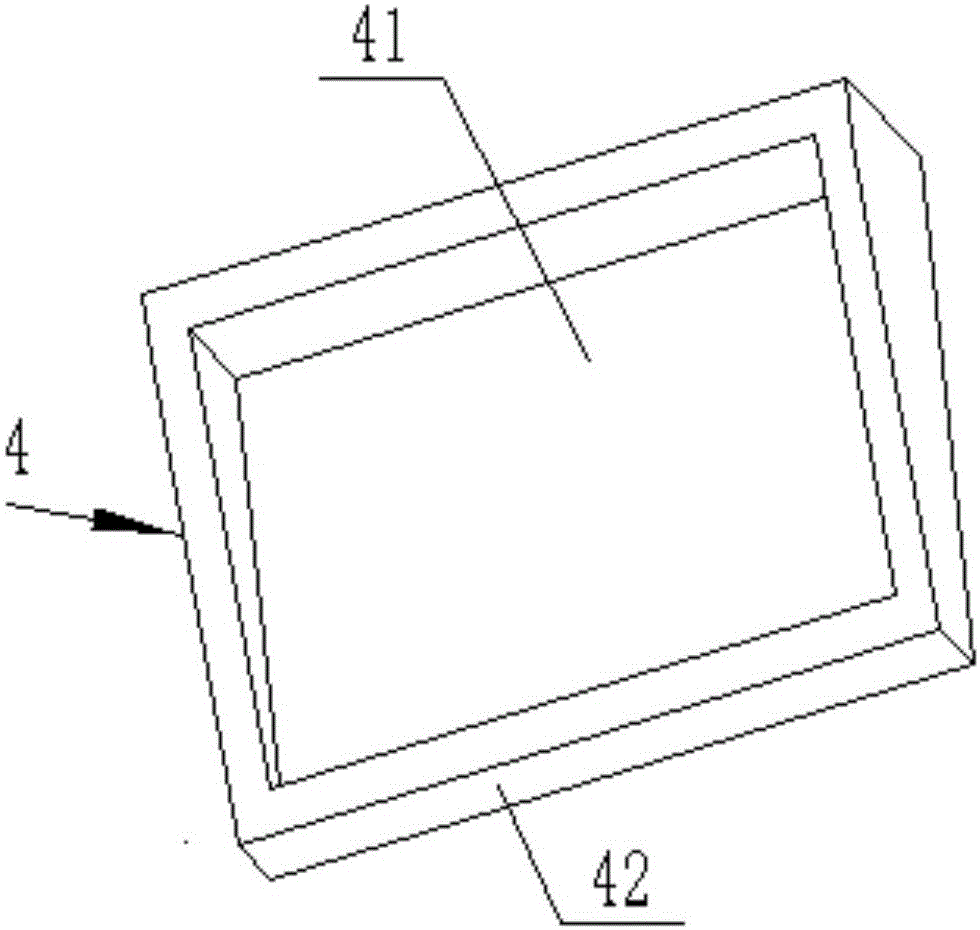

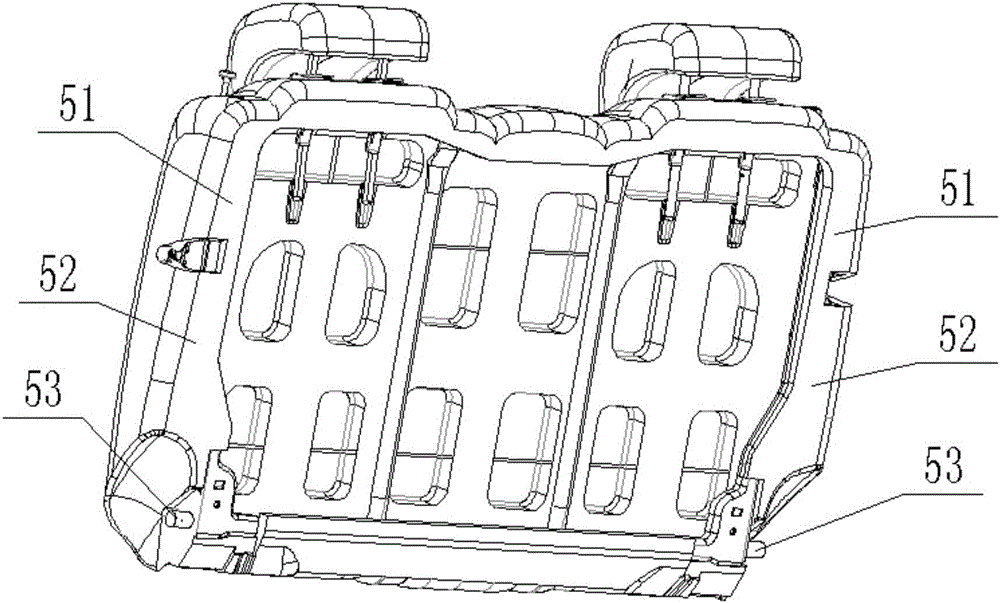

[0027] see Figure 1-3 , a synchronous assembly tooling for the seat back and seat foam, including a work station board 1, a foam tooling 2 for supporting and positioning the seat foam 4, and a backrest tooling 3 for supporting and positioning the seat back 5, The foam tooling 2 and the backrest tooling 3 are respectively installed on the two assembly line operation sides of the station board 1; the station board 1 is a rectangular board, and the length direction of the station board 1 is on the assembly line. direction of movement: a plurality of cylindrical buffer blocks 11 are respectively installed on both sides of the length direction of the station board 1, and when two adjacent station boards 1 collide with each other, the buffering effect is realized by the cylindrical buffer blocks 11, so There are buffer gaps 12 on both sides of the length directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com