Automatic production line of slender special-shaped pipes

An automatic production line and special-shaped tube technology, which is applied in the direction of automatic in/out of workpieces, metal processing machinery parts, metal processing, etc., can solve the problems of high scrap rate, low production efficiency of manual processing of slender special-shaped tubes, and automatic processing that cannot be positioned multiple times Problems such as multiple tool changes have achieved the effects of high authenticity rate, shortened processing cycle, and reduced handling links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

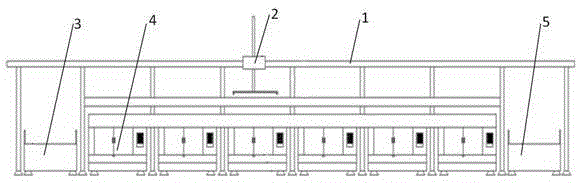

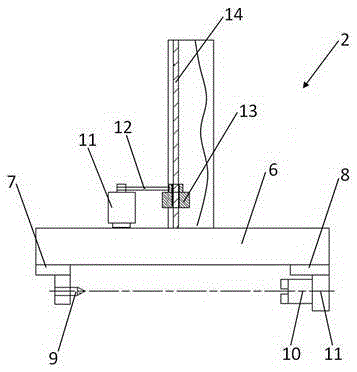

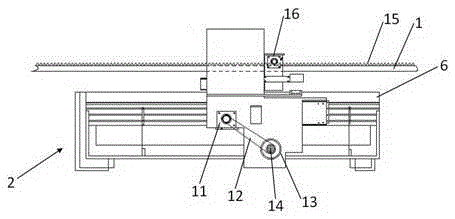

[0027] Such as Figure 1~4 As shown, an automatic production line for slender special-shaped pipes includes a truss 1, an upper hopper 3, a processing center 4, and a lower hopper 5. The upper hopper 3, multiple processing centers 4, and the lower hopper 5 are along the The beam of 1 is arranged in a straight line, and the truss manipulator 2 is arranged on the truss 1, and the truss manipulator 2 includes a clamping mechanism, a turning mechanism, a lateral movement mechanism, and a longitudinal movement mechanism.

[0028] The truss manipulator 2 can clamp the workpiece from the upper bin 3, and send the workpiece to the machining center 4 to process the predetermined position through the combination of the lateral movement mechanism and the longitudinal movement mechanism, and rotate the workpiece through the turning mechanism. Thus, each surface of the workp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com