Production technology and equipment for preparing ammonium sulfate through byproduct of tert-butylamine production process

A production process, ammonium sulfate technology, applied in ammonia compounds, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of equipment corrosion, high energy consumption, difficult processing, etc., to increase the reaction time, reduce the number of pumps, The effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

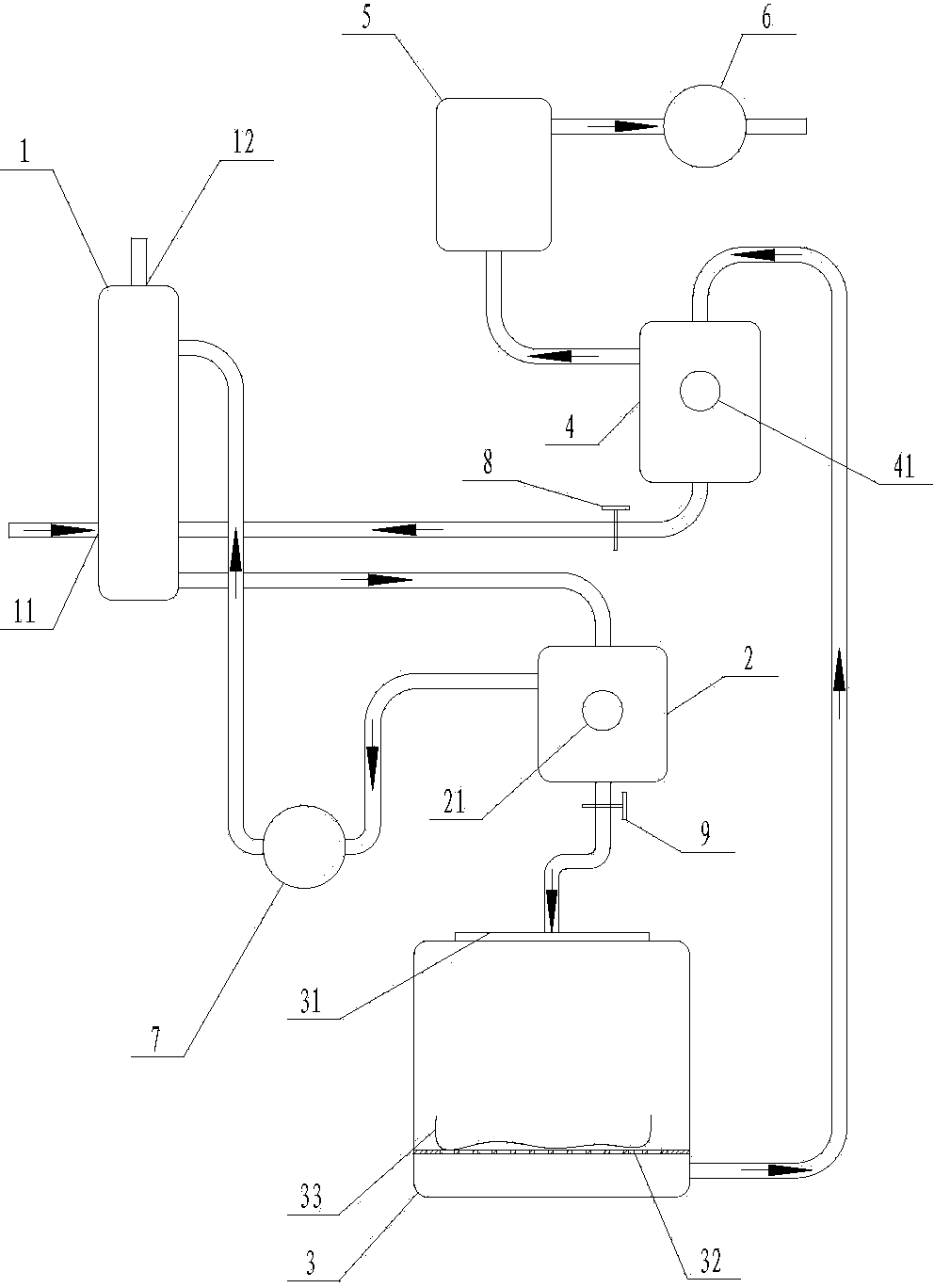

[0025] As shown in the figure, an equipment for preparing ammonium sulfate by using the by-products in the production process of tert-butylamine, including ammonia neutralization cooling tower 1, solid-liquid separator 2, vacuum filtration tank 3, vacuum tank 4, heat exchanger 5, vacuum pump 6. Circulating centrifugal pump 7, first valve 8 and second valve 9.

[0026] The bottom of the ammonia neutralization cooling tower 1 communicates with the top of the solid-liquid separator 2 and the bottom of the vacuum tank 4 through pipelines, and the upper part of the ammonia neutralization cooling tower 1 communicates with the circulating centrifugal pump 7 through pipelines, and the ammonia neutralization cooling An air inlet 11 and a sulfuric acid inlet 12 are provided on the body of the tower 1. The connection between the tower body and the pipeline is the outlet or inlet, which will not be described here.

[0027] The top of the solid-liquid separator 2 is lower than the bottom ...

Embodiment 2

[0037] Different from Embodiment 1, in this embodiment, when the volume of crystals in the solid-liquid separator 2 reaches 60% of the total volume of solids and liquids, and at the same time ensure that the bottom of the observation port 21 is not exceeded, the second valve 9 is opened to displace the crystals. Put into the suction filtration in the vacuum filtration tank 3.

Embodiment 3

[0039] Different from Embodiment 1, in this embodiment, when the volume of crystals in the solid-liquid separator 2 reaches 90% of the total volume of solids and liquids, while ensuring that the bottom of the observation port 21 is not exceeded, the second valve 9 is opened to displace the crystals. Put into the suction filtration in the vacuum filtration tank 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com